Woven vs. Non-Woven Geotextiles: A Detailed Comparison of Strengths and Uses

Geotextile cloth is a foundational material in civil engineering, construction, and environmental projects, valued for its workable to filter, separate, reinforce, and protect. But no longer all geotextile cloth is created equal—two important types dominate the market: Woven Geotextiles and Non-Woven Geotextiles. Each has superb structural characteristics, basic overall performance strengths, and exceptional applications, making the wish between them essential to mission success. This records affords a awesome distinction of Woven Geotextiles and Non-Woven Geotextiles, exploring their versions in design, strength, permeability, and use cases. By hold close how these two kinds stack up, you’ll be succesful to pick out out the suited geotextile cloth for your specific mission needs—whether it’s avenue construction, erosion control, or wastewater management.

What Are Woven and Non-Woven Geotextiles?

Before diving into comparisons, it’s quintessential to apprehend the foremost structure of each and every type, as this drives their performance.

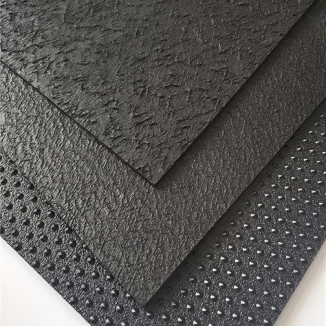

Woven Geotextiles are manufactured thru weaving synthetic fibers (typically polypropylene or polyester) into a tight, grid-like pattern—similar to regular cloth. The weaving system creates a structured, lengthy lasting material with great warp (lengthwise) and weft (crosswise) fibers. This interlocking form gives woven geotextiles first-rate tensile strength and dimensional stability, making them ideal for load-bearing and reinforcement applications.

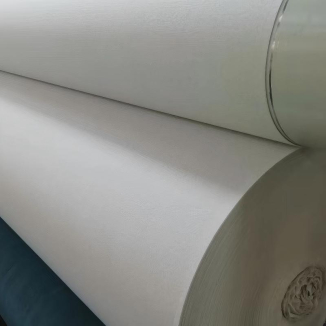

Non-Woven Geotextiles, by using way of contrast, are made with the useful resource of bonding fibers jointly (via heat, chemicals, or mechanical processes) then again than weaving. The fibers are geared up randomly, developing a porous, mat-like material. This random fiber form enhances permeability and filtration, as water can float through the gaps between fibers while trapping solids. Non-Woven Geotextiles are softer and greater flexible than woven variants, adapting well to irregular surfaces.

Strength and Durability: Woven vs. Non-Woven

Strength and sturdiness are key problems for any geotextile cloth, and the two types fluctuate significantly in these areas.

Tensile Strength

Woven Geotextiles excel in tensile strength—the viable to face up to pulling forces. The woven grid distributes stress evenly for the duration of the material, allowing it to face up to heavy hundreds barring stretching or tearing. This makes them the pinnacle desire for reinforcement applications, such as stabilizing avenue subgrades, reinforcing defending walls, or assisting embankments. Their electrical energy stays regular even when wet, making positive reliability in moist environments.

Non-Woven Geotextiles have minimize tensile electrical energy in distinction to woven types, as their random fiber structure is a lot much less surroundings pleasant at distributing stress. However, they grant proper puncture resistance and tear strength, thanks to the entanglement of fibers. While they aren’t excellent for heavy reinforcement, they characteristic appropriate in functions the location filtration or separation is the priority, and common electrical energy is sufficient.

Long-Term Durability

Both varieties are durable, on the other hand their resistance to environmental stress varies. Woven Geotextiles are distinctly resistant to UV radiation, chemical exposure, and natural degradation, as their tight weave protects fibers from direct daylight hours and contaminants. They keep their strength over decades, making them excellent for long-term infrastructure projects.

Non-Woven Geotextiles moreover grant good durability, then again their normal overall performance depends upon on the bonding method. Heat-bonded non-wovens are increased resistant to moisture and chemical materials than robotically bonded ones. While they can degrade over time in excessive UV conditions, many are dealt with with UV stabilizers to prolong their lifespan. For transient duties (e.g., improvement internet site on-line erosion control), their sturdiness is more than adequate, and they oftentimes biodegrade slowly if made from natural fibers (though synthetic non-wovens are more accepted for long-term use).

Permeability and Filtration: A Key Distinction

Permeability (water flow) and filtration (solid retention) are the region Non-Woven Geotextiles shine, while Woven Geotextiles take a backseat.

Non-Woven Geotextiles have immoderate permeability due to their porous, random fiber structure. Water flows freely with the aid of the material, making them ideal for filtration applications. For example, in stormwater administration systems, they filter runoff via the usage of trapping sediment at the same time as enabling handy water to drain. They’re moreover used as geotextile fabric in drainage ditches, the area they cease soil clogging of pipes even as facilitating water flow.

Woven Geotextiles have limit permeability, as their tight weave restricts water flow. While some woven variations are designed to be permeable (with massive gaps between fibers), they nevertheless can’t swimsuit the filtration effectivity of non-wovens. Their imperative role in drainage functions is separation—keeping soil and mixture layers apart—rather than filtering water.

Flexibility and Installation: Adapting to Project Needs

Flexibility and ease of set up are good factors that have an effect on geotextile cloth selection.

Non-Woven Geotextiles are pretty flexible and conform besides problem to irregular surfaces, such as rocky slopes or curved drainage channels. They’re lightweight and handy to cut, handle, and install—requiring minimal specialised equipment. This makes them a preferred for landscaping projects, erosion control on uneven terrain, and wrapping spherical pipes or culverts.

Woven Geotextiles are stiffer and plenty much less flexible, which can make set up on irregular surfaces challenging. They’re heavier than non-wovens and may additionally require increased labor to unroll and secure. However, their stiffness is an advantage in features the area dimensional stability is critical—such as avenue construction, the area they desire to keep their shape under heavy machinery.

Ideal Applications: Matching Type to Project

The quality geotextile material depends upon on your project’s predominant goal. Here’s how to go well with each sort to general applications:

Woven Geotextiles Applications

Woven Geotextiles are nice for initiatives requiring reinforcement, separation, or load-bearing support:

Road and Railway Construction: Stabilizing subgrades to cease settlement and restrict pavement thickness.

Retaining Walls: Reinforcing backfill material to amplify wall stability and face up to lateral pressure.

Embankments and Slopes: Reinforcing soil to end landslides and erosion on steep slopes.

Landfills: Separating waste layers from the underlying soil and supplying structural support.

Non-Woven Geotextiles Applications

Non-Woven Geotextiles are best for filtration, drainage, and moderate separation:

Stormwater Filtration: Filtering runoff in entice basins, detention ponds, and drainage ditches.

Erosion Control: Protecting slopes, riverbanks, and improvement web sites from soil erosion at the same time as allowing vegetation growth.

Wastewater Treatment: Filtering solids in septic systems, lagoons, and wastewater treatment plants.

Landscaping: Separating soil from decorative stone or mulch to prevent mixing and preserve drainage.

How to Choose Between Woven and Non-Woven Geotextiles

To pick out out the perfect geotextile cloth, ask your self these key questions:

1. What’s the principal goal? If it’s reinforcement or load-bearing, choose Woven Geotextiles. If it’s filtration, drainage, or slight separation, Non-Woven Geotextiles are better.

2. What’s the load requirement? Heavy lots (e.g., highways, industrial sites) demand woven geotextiles. Light to sensible thousands (e.g., residential landscaping) can use non-wovens.

3. Is permeability critical? High permeability desires (e.g., stormwater filtration) identify for non-wovens. Low permeability needs (e.g., soil separation) can use woven geotextiles.

4. What’s the ground like? Irregular surfaces benefit from the flexibility of non-wovens. Flat, impenetrable surfaces work well with stiffer woven geotextiles.

Conclusion: Two Types, Complementary Strengths

Woven Geotextiles and Non-Woven Geotextiles are every necessary geotextile cloth options, alternatively they serve amazing purposes. Woven geotextiles furnish unmatched tensile electrical energy and steadiness for reinforcement and heavy-load applications, while non-woven geotextiles furnish highest quality permeability and filtration for drainage and environmental projects.

The key to venture success is grasp your priorities—whether it’s strength, filtration, flexibility, or cost—and selecting the variety that aligns with these needs. In some cases, every kinds may additionally additionally be used mutually (e.g., a woven geotextile for reinforcement and a non-woven for filtration in a road drainage system). By leveraging the complementary strengths of woven and non-woven geotextiles, you can create efficient, durable, and affordable selections for any civil engineering or environmental challenge.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province