Case Study: How a Cement Blanket Saved Time on a Road Construction Project

In the realm of street construction, time is no longer simply a measure of progress; it is the lifeblood of the complete project. Every day of prolong can lead to a cascade of problems, from escalating expenses to disruptions in transportation and public inconvenience. Road initiatives are complicated undertakings, involving more than one stakeholders, giant groups of workers, and a sizable array of substances and equipment.

The longer a street development undertaking takes, the greater the charges related with labor, machinery, and materials. Delays can additionally end result in overlooked deadlines, which may additionally lead to economic penalties. Moreover, prolonged development intervals can purpose visitors congestion, detours, and protection dangers for motorists and pedestrians alike.

This is the place progressive options like the Flexible Concrete Blanket, additionally acknowledged as cement canvas or cement cloth, come into play. These modern substances have the workable to appreciably limit the time required for avenue development projects, making them greater efficient, price - effective, and much less disruptive to the public. By streamlining the building process, a cement blanket can assist contractors meet deadlines, retailer money, and enhance the normal first-class of the completed road.

The Traditional Road Construction Conundrum

The Labor - Intensive Mixing and Pouring

In normal street construction, the procedure of making ready and making use of cement is a labor - intensive and time - ingesting affair. First, employees need to accumulate the crucial materials: cement powder, sand, gravel, and water. Cement, in its uncooked form, is a satisfactory powder that serves as the binding agent for the street - constructing mixture. The sand and gravel act as aggregates, imparting bulk and steadiness to the remaining product.

The mixing system is the place the complexity begins. Workers have to cautiously measure and mix these substances in specific ratios. This regularly includes the usage of giant - scale mixing equipment, which wants to be set up, calibrated, and maintained. Manual labor is additionally required to make sure that the combination is absolutely blended. Any miscalculation in the ratios can lead to a sub - preferred street surface, both too brittle or now not sturdy adequate to face up to visitors loads.

Once the combination is ready, the pouring manner commences. Workers need to transport the moist cement combination to the development site, which can be challenging, mainly in giant - scale tasks the place the distance between the mixing place and the roadbed is significant. Pouring the cement evenly and easily over the organized roadbed requires expert labor. Even small imperfections at some stage in pouring can end result in an uneven avenue surface, which can purpose issues such as water pooling, uneven wear, and expanded automobile vibration over time. This labor - intensive mixing and pouring method can take days or even weeks, relying on the dimension of the street project.

Curing Time: A Lengthy Wait

After the cement has been poured, the subsequent hurdle is the curing time. Curing is the system by means of which the cement hardens and good points strength. Traditional cement combos commonly require a exceptionally lengthy length to remedy properly. This is due to the fact the chemical reactions inside the cement - water - combination combination want time to attain completion.

During the curing process, the street ought to be left undisturbed as plenty as possible. Any exterior forces, such as site visitors or heavy gear movement, can disrupt the curing system and weaken the last shape of the road. This potential that building work in the neighborhood may additionally have to be halted, and visitors diversions want to be maintained for an prolonged period.

The curing time for normal cement can vary from a number of days to weeks. For example, in everyday climate conditions, a popular concrete street may also want at least 7 - 10 days to attain a enough electricity for mild traffic, and up to 28 days to gain its full graph strength. This lengthy curing time is a foremost bottleneck in the street building schedule. It now not solely extends the ordinary undertaking period however additionally will increase the fees related with website online management, visitors control, and tools idling. In addition, unfavourable climate conditions, such as excessive humidity, low temperatures, or heavy rainfall, can similarly extend the curing time or even harm the curing cement, main to extra delays and achievable rework.

Enter the Cement Blanket: A Revolutionary Solution

What Exactly is a Cement Blanket?

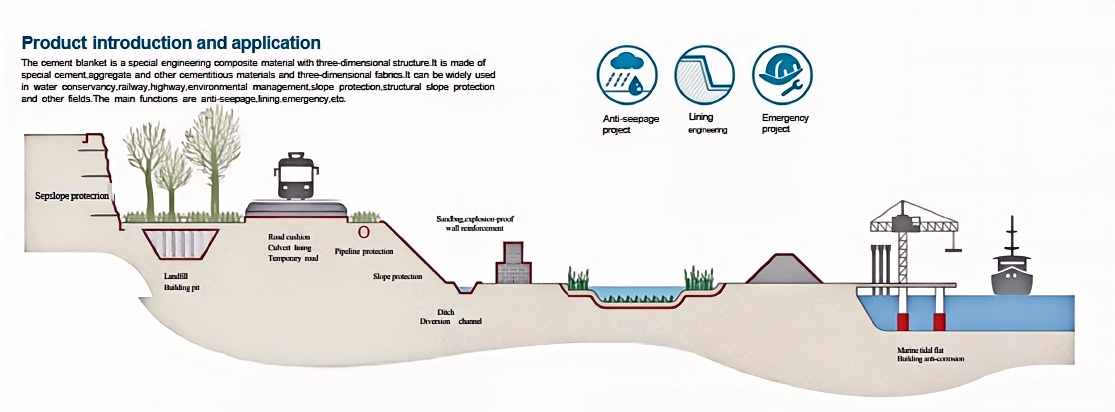

A cement blanket, additionally regarded as Flexible Concrete Blanket, cement canvas, or cement cloth, is a modern building cloth that has been making waves in the avenue building industry. This progressive product combines the power and sturdiness of usual cement with the flexibility and comfort of a cloth - like material.

At its core, a cement blanket is composed of a combination of dry cement and a fibrous material, usually a artificial fiber such as polyester or a herbal fiber like jute. The cement is evenly allotted at some stage in the fiber matrix, developing a homogeneous structure. The fibers serve more than one purposes: they furnish reinforcement to the cement, improving its tensile energy and flexibility. This special mixture approves the cement blanket to be rolled up or folded, making it surprisingly transportable and effortless to transport to the building site. It can be without problems maneuvered round barriers and into tight spaces, not like usual giant - scale cement - pouring equipment.

For example, in a small - scale avenue restore mission in a slender alley, a cement blanket can be carried with the aid of a couple of employees and unrolled at once onto the broken area. This is in stark distinction to the typical method, which would require a giant cement mixer truck to be parked nearby, regularly inflicting site visitors disruptions in the already - congested alley. The dimension and form of a cement blanket can differ relying on the producer and the meant application, however they are normally on hand in giant sheets that can be reduce to in shape the unique necessities of a project.

The Science Behind Its Quick - Acting Properties

One of the most superb points of a cement blanket is its capacity to harden hastily upon contact with water. When the dry cement inside the blanket comes into contact with water, a chemical response referred to as hydration occurs. This is the equal essential method that takes area in ordinary cement - based totally mixtures, however it takes place a whole lot greater shortly in a cement blanket.

The special shape of the cement blanket performs a necessary function in this accelerated hydration process. The fibers in the blanket act as a wicking agent, drawing water evenly in the course of the cement matrix. This ensures that the cement is uniformly hydrated, ensuing in a greater regular and better ultimate product. In usual cement mixing, reaching a uniform distribution of water can be challenging, regularly main to versions in the curing procedure and the first-class of the closing structure.

Moreover, the cement in a cement blanket is formulated to have a excessive reactivity with water. Special components can also be blanketed in the cement combination to velocity up the hydration process. These components can decrease the activation electricity required for the chemical reactions to occur, allowing the cement to harden in a be counted of hours alternatively than days, as is the case with normal cement. For instance, in some street building tasks the place time is of the essence, a cement blanket can be saturated with water in the morning and be equipped to guide mild site visitors by means of the afternoon, notably lowering the development time and minimizing disruptions to the public.

Case Study Breakdown

Project Background and Initial Hurdles

The street development venture in query was once a fundamental hyperlink in a primary transportation network. It used to be designed to enhance connectivity between two industrial zones, which would now not solely enhance financial improvement however additionally relieve visitors congestion on present roads. The task was once positioned in a semi - city area, with a combine of residential neighborhoods, small businesses, and agricultural land nearby.

However, the task confronted countless full-size challenges from the start. One of the most urgent troubles used to be the tight deadline. The neighborhood authorities had set a strict timeline of six months for the completion of the road, as it was once section of a large infrastructure improvement plan. Any prolong in this assignment may want to have a domino impact on different associated tasks in the area.

Another undertaking was once the terrain. The avenue had to traverse thru a hilly area, which required full-size earth - shifting and grading work. Traditional avenue development strategies had been already time - consuming, and the complicated terrain made the procedure even extra arduous. In addition, the mission website used to be on hand solely via slim rural roads, which made it tough to transport giant building tools and materials, similarly including to the logistical challenges.

Implementing the Cement Blanket

The selection to use a cement blanket in this challenge used to be a recreation - changer. The first step in imposing the cement blanket was once website preparation. Workers cleared the location of any debris, vegetation, and unfastened soil. They then graded the floor to make sure a clean and even base for the cement blanket.

Once the website was once prepared, the cement blankets, additionally recognized as Flexible Concrete Blankets or cement canvas, had been delivered to the site. These blankets have been rolled out alongside the size of the roadbed. Since they have been light-weight and flexible, they should be without difficulty maneuvered round the curves and slopes of the hilly terrain. Workers used easy hand - held equipment to reduce the blankets to the suitable dimension and shape, making sure a ideal in shape for every part of the road.

As the blankets have been laid, water was once sprayed onto them the usage of a hose. This brought on the hydration technique in the cement inside the blankets. Workers had to be cautious not to over - saturate the blankets with water, as this should lead to uneven hardening. They additionally had to make sure that the water was once dispensed evenly throughout the floor of the blankets. After the water was once applied, the people used rollers to gently press the blankets onto the roadbed, getting rid of any air pockets and making sure appropriate adhesion.

Time Comparison: Traditional vs Cement Blanket

In the earth - transferring and grading stage, common strategies took about two weeks. This worried the usage of giant bulldozers, graders, and dump vans to reshape the terrain. In contrast, with the use of a cement blanket, the website online practise and laying of the blanket in the identical region took solely one week. The flexibility of the cement blanket allowed for faster adaptation to the terrain, lowering the want for vast grading work.

When it got here to the cement - laying process, typical cement mixing and pouring took every other three weeks. This protected the time for mixing the cement, transporting it to the site, and cautiously pouring and leveling it. With the cement blanket, the whole manner of laying the blankets and initiating the hardening took solely three days. The fast - hardening houses of the cement blanket intended that there was once no want for the lengthy - ready instances related with common cement curing.

For the curing period, common cement required at least two weeks of undisturbed time to attain ample strength. During this time, visitors had to be diverted, and building things to do in the neighborhood have been restricted. In contrast, the cement blanket used to be prepared to assist mild site visitors inside 24 - forty eight hours after software of water, and full - energy used to be accomplished inside a few days. This big discount in curing time allowed for a an awful lot until now reopening of the avenue to the public, minimizing disruptions to neighborhood organizations and residents. Overall, with the aid of the usage of a cement blanket, the whole development time for this avenue undertaking was once decreased from the originally projected six months to simply 4 months, a 33% discount in time.

Additional Advantages Beyond Time - Saving

Cost - Efficiency

The use of a cement blanket, additionally recognized as cement canvas or cement cloth, brings considerable value - effectivity advantages to street building projects. One of the important value - saving factors is the discount in labor requirements. Traditional avenue construction, with its labor - intensive mixing and pouring processes, needs a giant workforce. Workers are wished to function the mixing equipment, transport the moist cement, and cautiously pour and stage it. In contrast, a cement blanket can be laid through a smaller group of workers. Since the blankets are light-weight and flexible, they can be effortlessly maneuvered and installed, requiring fewer fingers on deck. This without delay cuts down on labor costs, which can be a tremendous component of the typical undertaking budget.

Moreover, the time saved at some stage in building by using the use of a cement blanket has a cascading impact on price reduction. With a shorter building period, there are fewer days of tools rental, decrease prices related with website management, and decreased visitors manipulate expenses. For example, if a venture is accomplished two months before due to the use of a cement blanket, the financial savings in gear condominium expenses for heavy - equipment like bulldozers and cement mixers can be substantial. Additionally, the decreased disruption to neighborhood companies and visitors for the duration of the shorter building duration can have intangible monetary benefits, such as minimizing misplaced commercial enterprise income due to accessibility issues.

Durability and Long - Term Performance

Cement blankets, or Flexible Concrete Blankets, are famend for their durability. The special composition of the cement inside the fibrous matrix contributes to its lengthy - lasting performance. The fibers beef up the cement, making it extra resistant to cracking and wear. In a street environment, the place the floor is continuously subjected to the stress of car traffic, temperature variations, and climate elements, sturdiness is crucial.

A long lasting avenue floor capability fewer repairs and renovation over time. Traditional roads might also require generic patching due to cracks, potholes, and uneven wear. These repairs no longer solely value cash in phrases of substances and labor however additionally purpose inconvenience to avenue users. In contrast, a avenue built with a cement blanket is much less probably to improve such problems in the quick to medium term. For instance, a cement - blanket - paved street might also want solely minor protection each few years in contrast to a common street that may additionally require annual or bi - annual foremost repairs. This long - time period sturdiness sooner or later saves each time and cash in the usual lifespan of the road, making the preliminary funding in a cement blanket a price - nice desire in the lengthy run.

Challenges and Solutions in Using Cement Blankets

Installation Complexities

While cement blankets provide severa advantages, their set up is now not except challenges. One of the foremost issues is terrain adaptability. In areas with extraordinarily rugged or uneven terrain, it can be challenging to make sure that the cement blanket lays flat and makes full contact with the ground. For example, in mountainous areas with massive boulders or steep inclines, the blanket may also now not conform flawlessly to the surface, leaving gaps or air pockets. These imperfections can weaken the integrity of the street over time, as water may additionally seep into the gaps and motive erosion or freeze - thaw damage.

Another set up complexity lies in the dealing with of the blankets in windy conditions. Since cement blankets are notably lightweight, robust winds can make it difficult to unroll and role them accurately. Workers may additionally fighting to maintain the blanket in place, and the hazard of the blanket being broken or torn for the duration of set up increases. This requires cautious planning, such as scheduling set up for the duration of calmer climate durations or the usage of brief anchors to keep the blanket in vicinity till it can be good secured.

Environmental Considerations

The environmental have an effect on of cement blankets is an vital thing to consider. While the use of a cement blanket can limit the usual development time and related environmental disruptions, there are nevertheless issues about the substances themselves. The cement used in the blankets, like regular cement, is produced thru a procedure that emits a huge quantity of carbon dioxide. This contributes to greenhouse fuel emissions and local weather change.

Moreover, the artificial fibers in some cement blankets might also now not be biodegradable. If these blankets quit up in landfills or the herbal surroundings at the give up of their lifespan, they can persist for a lengthy time, doubtlessly inflicting pollution. However, there are methods to mitigate these environmental concerns. Some producers are exploring the use of greater sustainable cement alternatives, such as geopolymers, which have a decrease carbon footprint. Additionally, lookup is being performed on the use of biodegradable fibers in cement blankets to minimize their lengthy - time period environmental impact. In the case of the avenue building assignment in our case study, the development organization labored with the producer to supply cement blankets made with a greater share of recycled materials, similarly minimizing the project's environmental footprint.

Conclusion: Cement Blankets - The Future of Road Construction?

In conclusion, the use of cement blankets, additionally regarded as Flexible Concrete Blankets, cement canvas, or cement cloth, in avenue building initiatives has demonstrated to be a recreation - altering innovation. As confirmed in the case study, these awesome substances provide a multitude of advantages, with time - saving being one of the most significant.

By doing away with the want for the labor - intensive and time - eating approaches of standard cement mixing, pouring, and lengthy - time period curing, cement blankets can substantially limit the typical development time. This no longer solely helps in assembly tight closing dates however additionally minimizes the disruptions to visitors and the surrounding communities. The challenge in our case find out about noticed a 33% discount in building time, which is a testomony to the effectivity of cement blankets.

Beyond time - saving, cement blankets convey fee - efficiency to the table. The decreased labor necessities and shorter development intervals lead to enormous financial savings in labor costs, tools rental, and website administration expenses. Their sturdiness additionally ensures lengthy - time period fee - effectiveness, as roads developed with cement blankets require fewer repairs and upkeep over time.

However, it is essential to well known the challenges related with cement blankets, such as set up complexities in rugged terrains and environmental considerations. But with ongoing lookup and development, options are being found. Manufacturers are exploring sustainable substances and increased set up methods to mitigate these issues.

Looking ahead, cement blankets have the plausible to grow to be a staple in avenue construction. As extra contractors and building groups emerge as conscious of their advantages and as the science continues to improve, we can count on to see an growing variety of street tasks making use of cement blankets. They provide a promising solution to the ever - developing demand for efficient, fee - effective, and long lasting avenue construction. In the future, cement blankets can also very properly redefine the way we construct roads, making the building procedure faster, extra sustainable, and much less of a burden on the surroundings and the public.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province