Geotextile 500g m2

1. High strength reinforcement: improves soil stability, suitable for roadbed, slope and other engineering projects.

2. Efficient permeable filtration: Drainage and sedimentation prevention to prevent soil erosion (such as dam filter layer).

3. Isolation and protection: prevent mixing of different materials and protect the anti-seepage layer (such as in landfills).

4. Convenient construction: Lightweight and easy to lay, suitable for complex terrain, saving time and cost.

5. Durable and environmentally friendly: corrosion-resistant, anti-aging, some materials can be recycled to reduce ecological damage.

Product Introduction:

Geotextile 500g m2 is a permeable geosynthetic material made of synthetic fibers (such as polyester, polypropylene, etc.) through processes such as needle punching, weaving, or thermal bonding. According to production processes and functions, it is mainly divided into the following types:

Process: Short fibers or long fibers are fixed into a three-dimensional network structure through needle punching, thermal bonding, or chemical bonding.

Features: Strong permeability, low cost, uniform tensile strength, suitable for isolation and filtration scenarios.

Subclass:

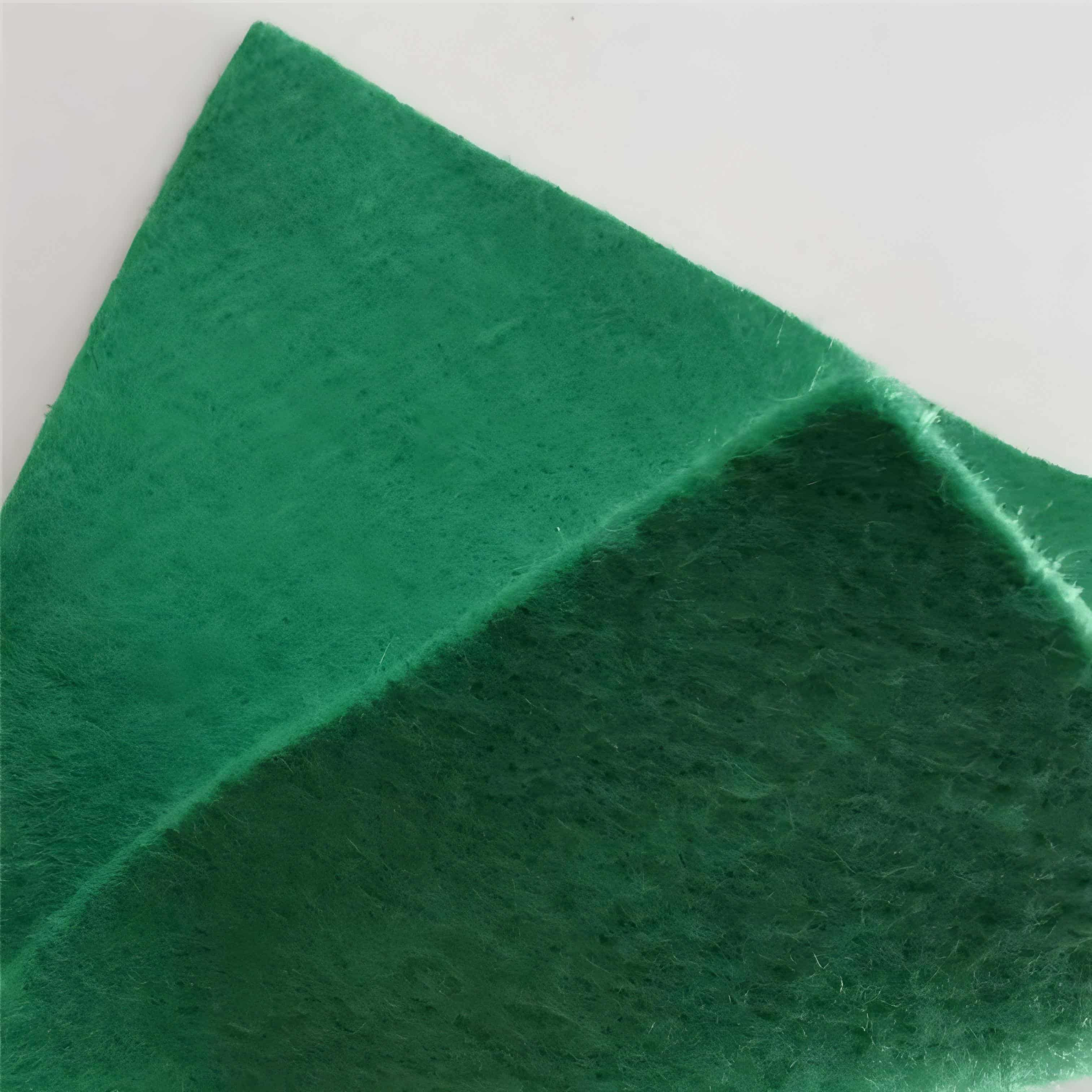

Short fiber needle punched geotextile: made of polyester or polypropylene short fibers as raw materials, the fibers are randomly arranged, suitable for slope protection and land improvement.

Filament anti sticking needle punched geotextile: It is made of polyester filament, with uniform pore distribution and strong aging resistance, and is commonly used in water conservancy project filter.

Process: A regular grid structure is formed by weaving synthetic fibers.

Features: High strength, outstanding deformation resistance, suitable for reinforcement and load-bearing scenarios (such as soft foundation treatment and coastal protection).

Fabric film composite: Non woven fabric and PE film composite (such as one fabric and one film, two fabrics and one film), with both anti-seepage and drainage functions, used in anti-seepage projects such as tunnels and landfills.

Multi layer composite: Non woven fabric and woven fabric composite can simultaneously achieve isolation and reinforcement functions, and are applied in complex scenarios such as roadbed reinforcement.

Divided by fiber type

Short fiber geotextile: Low cost, good flexibility, suitable for temporary projects or projects with limited budgets.

Long fiber geotextile: Its tensile strength can reach 2-3 times that of short fiber fabric, and its corrosion resistance is better. It is used for high demand permanent engineering.

core features

1. Physical properties

High strength: Plastic fibers can maintain strength and elongation in both dry and wet conditions, with uniform tensile strength.

Permeability: The gaps between fibers form drainage channels, effectively removing excess moisture.

Corrosion resistance: resistant to acid and alkali erosion, extending service life.

Antimicrobial: immune to insect infestation and microbial damage.

2. Construction advantages

Lightweight and Soft: The material is lightweight and soft, making it easy to transport, lay, and construct.

Complete specifications: with a width of up to 9 meters and a unit area mass of 100-1000g/m ², suitable for different engineering needs.

Environmental friendliness: non-toxic and odorless, does not pollute the environment, and meets the requirements of sustainable development.

major function

1. Filtering function

Prevent water flow from carrying away soil particles, protect soil structure, and maintain engineering stability. For example, intercepting fine sand and small stones in dam engineering to prevent soil erosion.

2. Drainage function

Form drainage channels to quickly remove excess water and enhance project stability. Burying geotextile in the roadbed of highways can dissipate the water pressure in the gaps.

3. Isolation function

Isolate different soil layers or materials (such as soil and sand, concrete) to prevent mixing and maintain overall structural functionality. For example, in road engineering, isolating the roadbed from the soft foundation to prevent uneven settlement.

4. Reinforcement effect

Form a composite with the soil, improve soil strength and stability, and prevent deformation. If used for backfilling and reinforcing retaining walls or reinforcing flexible road surfaces.

5. Protective function

Prevent water erosion and erosion, protect the stability of bank slopes and riverbeds. For example, laying geotextiles in river management can reduce the damage of water flow to embankments.

6. Anti seepage and anti filtration

Composite with geomembrane to form anti-seepage material, preventing liquid infiltration; At the same time, as an anti filter layer, it allows water to pass through while retaining soil particles. The application of a one cloth one membrane structure in landfills.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Dam engineering

Anti seepage and anti filtration: Geotextile is used as the anti-seepage layer of dams to prevent damage such as pipe surge and soil flow caused by water infiltration. At the same time, as an anti filtration layer, it allows water to pass through and intercept soil particles, maintaining the stability of the dam.

Drainage system: Lay geotextile inside the dam to form drainage channels, quickly remove excess water, and reduce the damage of water pressure to the dam.

Slope protection: Cover the embankment slope with geotextile to resist water erosion, prevent soil loss, and protect the integrity of the slope structure.

Channel Engineering

Reduce leakage: Lay geotextile at the bottom and slope of the channel to reduce water leakage and improve water delivery efficiency.

Prevent erosion: Geotextile isolates water flow from soil, preventing the bottom and slope of the channel from being washed away by water flow and extending the service life of the channel.

River training

Bank protection material: Geotextile is used as a part of the bank protection structure to prevent water flow from directly scouring the riverbank and protect the soil on the riverbank from erosion.

2. Transportation Engineering

highway engineering

Roadbed reinforcement: Laying geotextile in the roadbed to improve its bearing capacity and stability, and prevent road collapse caused by foundation settlement.

Slope protection: Cover the slope with geotextile to prevent rainwater and surface water from washing away the slope soil and maintain slope stability.

Drainage system: Geotextile is used as a drainage material to help remove moisture from the roadbed and pavement, preventing damage to the road due to excessive moisture.

Asphalt pavement crack prevention: Laying geotextile in asphalt pavement can delay the occurrence and development of pavement cracks and extend the service life of the pavement.

railway engineering

Track bed isolation: Laying geotextile in the railway track bed plays a role in drainage and isolation, preventing ballast from being embedded in the roadbed and extending the service life of the railway.

Roadbed reinforcement: Geotextile is used as a reinforcement material for railway roadbeds to enhance the bearing capacity of the foundation and reduce roadbed settlement.

Antifreeze insulation: In cold regions, geotextiles can be used as insulation layers for frost and frost prevention, reducing damage to railway infrastructure caused by frost heave.

Airport project

Runway anti settlement: Geotextile is laid under the airport runway to prevent deformation due to foundation settlement and ensure flight safety.

Drainage system: Geotextile is used as a drainage material to help remove moisture from the runway and apron, preventing water accumulation from affecting aircraft takeoff and landing.

3. Environmental Protection Engineering

Landfill site

Anti seepage system: Geotextile is laid at the bottom and slopes of the landfill site, combined with geotextile and other materials to form a complete anti-seepage system, preventing the pollution of groundwater and soil by leachate from garbage.

Enhance stability: Geotextile enhances the stability of landfill sites to prevent accidents such as garbage landslides and collapses.

sewage-treatment plant

Pool body anti-seepage: used for anti-seepage and corrosion prevention of regulating tanks, sedimentation tanks and other pool bodies in sewage treatment plants, protecting the structure of the pool body from sewage erosion.

Filter material: As a filter material for biological filters, it improves the efficiency of sewage treatment and removes suspended solids and harmful substances from sewage.

tailing pond

Drainage of rainwater: Geotextile is used in the drainage system of tailings ponds to help remove rainwater and reduce the risk of dam failure.

Prevent leakage: Lay geotextile at the bottom of the tailings pond to prevent tailings liquid from leaking and polluting the surrounding environment.

4. Construction Engineering

basement waterproofing

Enhance waterproof performance: Geotextile, as a part of the basement waterproof system, is used in conjunction with waterproof coatings, waterproof rolls, etc. to enhance the waterproof performance of the basement and prevent groundwater intrusion.

roofing

Improve tear resistance: Lay geotextile in the roof waterproof layer as a reinforcement material to enhance the tear resistance and puncture resistance of the waterproof layer, and extend the service life of the roof waterproof layer.

foundation treatment

Reinforced foundation: Geotextile is used for foundation treatment of buildings, helping to reinforce the foundation and improve the stability of the building.

Isolation and filtration: As an isolation and filtration material in the foundation, it prevents mixing of different soil layers and maintains the stability of the foundation structure.

5. In the field of agriculture

saving irrigation

Precise water control: Geotextiles are used in water-saving irrigation systems to achieve precise water control and improve water resource utilization efficiency.

Prevent leakage: Lay geotextile in irrigation channels to reduce water leakage and ensure that irrigation water effectively reaches crop roots.

improvement of saline-alkali

Blocking salt migration: Geotextiles are used in saline alkali land improvement projects to block salt migration, reduce soil salinity, and improve soil quality.

Greenhouse

Sunshade adjustment: Geotextile serves as a sunshade net for greenhouses, regulating the temperature and light intensity inside the greenhouse to provide a suitable environment for crop growth.

Foundation reinforcement: Lay geotextile in the greenhouse foundation to enhance the bearing capacity of the foundation and prevent damage to the greenhouse due to foundation settlement.

6. Disaster prevention and control

Emergency landslide repair

Rapid laying of reinforced grid cloth: In emergency landslide repair, rapid laying of reinforced grid cloth enhances soil stability and prevents further expansion of landslides.

Drainage in flood stricken areas

Constructing temporary drainage channels: In flood stricken areas, geotextiles are used to construct temporary drainage channels to quickly drain accumulated water and reduce the impact of disasters.

The application of geotextile covers almost all engineering fields involving the interaction between soil, water, and structure. Its core value lies in solving practical problems in engineering through the physical properties of materials, while also possessing advantages such as convenient construction, controllable cost, and ecological compatibility. It is an indispensable key material in modern engineering construction.