Why Geotextile Cloth Outperforms Traditional Materials (Straw, Hay, or Gravel)

For decades, straw, hay, and gravel have been go-to materials for erosion control, soil stabilization, and driveway construction. However, as infrastructure and landscaping initiatives demand larger durability, efficiency, and long-term value, geotextile fabric has emerged as a greatest alternative. Geotextile cloth, a artificial or herbal fiber cloth engineered for geotechnical applications, addresses the inherent barriers of regular substances whilst handing over more desirable overall performance throughout various scenarios. This article explores three key motives why geotextile material outperforms straw, hay, and gravel, highlighting its function in geotextile soil stabilization, driveway construction, and beyond.

1. Superior Geotextile Soil Stabilization: Long-Term Structural Integrity vs. Temporary Fixes

Soil stabilization is fundamental for stopping erosion, preserving slope stability, and helping structural hundreds in building and landscaping projects. Traditional substances like straw and hay provide brief erosion manage however fail to furnish lasting soil stabilization, whilst gravel regularly struggles with compaction troubles and uneven load distribution. In contrast, geotextile fabric is mainly designed to strengthen soil structure, handing over long-term balance that common substances can't match.

Straw and hay act as floor mulch to gradual water runoff and shield topsoil, however they decompose rapidly—typically inside 6 to 12 months—leaving the soil unprotected afterward. This decomposition additionally provides natural count number that can disrupt soil pH stability and entice pests, requiring regular reapplication. Gravel, whilst extra long lasting than straw or hay, tends to sink into tender soil over time, main to uneven surfaces, potholes, and decreased load-bearing capacity. These problems are especially complex in high-traffic areas or areas with heavy rainfall.

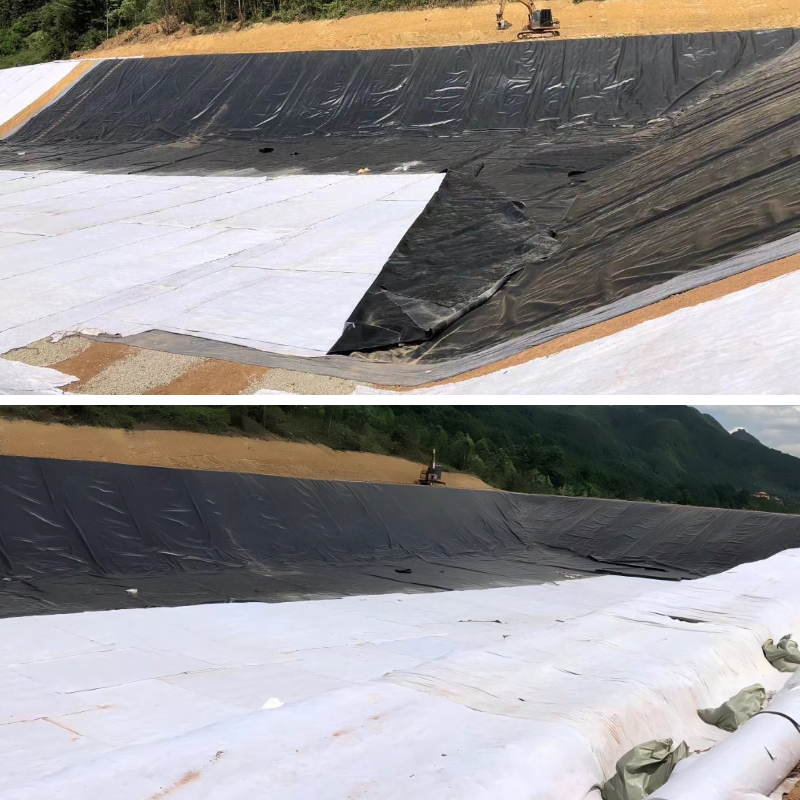

Geotextile fabric solves these challenges via its engineered fiber structure, which creates a steady barrier that distributes masses evenly throughout the soil surface. In geotextile soil stabilization projects, the cloth interlocks with soil particles, stopping lateral motion and lowering erosion brought on by means of water and wind. Non-woven geotextile cloth, in particular, provides excessive permeability, permitting water to drain whilst keeping soil particles— a stability that straw, hay, and gravel can't achieve. For example, in avenue construction, setting geotextile material under the gravel base enhances load distribution, extending the road’s lifespan through up to 50% in contrast to gravel-only installations. This long-term balance eliminates the want for widely wide-spread repairs and reapplication, decreasing ordinary undertaking costs.

2. Enhanced Durability & Low Maintenance: Outlasting Straw, Hay, and Gravel

Durability and upkeep necessities are key elements in fabric choice for any development or landscaping project. Traditional substances like straw and hay are inherently fragile, whilst gravel requires normal protection to preserve performance. Geotextile cloth, however, presents magnificent sturdiness and minimal maintenance, making it a greater low cost preference over the lengthy term.

Straw and hay are relatively prone to weathering, decomposition, and injury from pests and rodents. In moist conditions, they take in water and end up heavy, dropping their erosion manage competencies and probably contributing to soil saturation. In dry conditions, they are inclined to blowing away or catching fire, requiring regular monitoring and replacement. Gravel, whilst greater weather-resistant, requires ordinary grading to repair uneven surfaces and replenish potholes. It additionally tends to migrate over time, in particular in areas with heavy visitors or water flow, main to high-priced upkeep efforts.

Geotextile material is engineered to stand up to harsh environmental conditions, consisting of severe temperatures, UV radiation, and chemical exposure. Synthetic geotextile material (made from polypropylene or polyester) is resistant to decomposition, rot, and pest damage, with a lifespan of 20 to 50 years relying on the application. Unlike straw and hay, it does no longer require reapplication, and in contrast to gravel, it keeps its shape barring migration or compaction issues. For instance, in agricultural applications, geotextile material used as a weed barrier eliminates the want for regular mulching with straw or hay, decreasing labor and cloth costs. In driveway construction, geotextile cloth for driveway installations prevents gravel from sinking into the soil, putting off the want for ordinary grading and extending the driveway’s lifespan with minimal maintenance.

3. Versatility & Multifunctional Applications: Adapting to Diverse Project Needs

One of the most sizable benefits of geotextile fabric is its versatility, as it can be tailor-made to meet the unique wants of numerous projects—from erosion manipulate and soil stabilization to driveway building and drainage systems. Traditional substances like straw, hay, and gravel have constrained applications, regularly requiring extra substances to obtain favored results.

Straw and hay are principally used for transient erosion manage and mulching, with little utility in structural functions like driveway development or slope stabilization. Gravel is beneficial for drainage and floor purposes however lacks the flexibility to adapt to varying soil prerequisites or challenge requirements. For example, gravel by myself can't efficiently forestall soil erosion on steep slopes, requiring extra substances like preserving partitions or mesh.

Geotextile cloth, by way of contrast, comes in a vary of kinds (woven, non-woven, and knitted) and weights, making it appropriate for a extensive array of applications. Woven geotextile material is best for geotextile soil stabilization and driveway construction, as it affords excessive tensile electricity and load-bearing capacity. Non-woven geotextile fabric is ideal for erosion control, drainage, and weed suppression, thanks to its excessive permeability and filtration capabilities. Geotextile material for driveway projects, for example, can be mixed with gravel to create a stable, long-lasting floor that handles heavy site visitors and prevents potholes. In coastal erosion control, geotextile fabric is used to beef up sand dunes and defend shorelines, outperforming straw bales which are shortly washed away by using waves.

Additionally, geotextile material works synergistically with different materials, bettering their performance. When used under gravel in driveways or roads, it improves drainage, reduces gravel migration, and extends the existence of the surface. When used with straw or hay in erosion manage projects, it affords a long-lasting base layer that extends the effectiveness of the natural mulch. This versatility makes geotextile material a one-stop answer for many assignment needs, reducing the want for more than one substances and simplifying installation.

Conclusion: Geotextile Cloth – The Superior Choice for Modern Projects

While straw, hay, and gravel have served their cause in regular building and landscaping, geotextile fabric has demonstrated to be a top of the line choice in phrases of soil stabilization, durability, and versatility. Its potential to supply long-term geotextile soil stabilization, minimal maintenance, and adaptability to various functions makes it a low in cost and dependable preference for present day projects. Whether used as geotextile material for driveway construction, erosion control, or drainage systems, geotextile fabric outperforms regular substances via addressing their inherent boundaries and handing over greater performance.

For challenge managers, contractors, and householders searching to maximize the value, durability, and sustainability of their projects, geotextile fabric is the clear choice. Its lengthy lifespan, low upkeep requirements, and multifunctional functions make it an funding that will pay off over time, outperforming straw, hay, and gravel in almost each scenario.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province