UV Resistance and Longevity: Key Geotextile Specifications for Outdoor Use

Outdoor construction, erosion control, and landscaping projects demand materials that can withstand the harshest elements—none more challenging than ultraviolet (UV) radiation. Geotextile cloth, a staple in these applications, relies heavily on UV resistance to maintain its structural integrity and performance over time. Without proper UV protection, even high-quality geotextiles can degrade, tear, or lose strength, leading to project failures, costly replacements, and environmental risks. This guide explores why UV resistance and longevity are non-negotiable geotextile cloth specifications for outdoor use, how materials like non woven filter cloth and geotextile blankets are engineered to resist UV damage, and what to look for when selecting products for your next outdoor project. By prioritizing these key traits, you can ensure your geotextiles deliver reliable, long-lasting results in sun-exposed environments.

The Impact of UV Radiation on Geotextile Cloth

UV radiation from the sun breaks down the molecular bonds in synthetic and natural materials—a process called photo-oxidation. For geotextile cloth, this degradation manifests in several ways: reduced tensile strength, brittleness, discoloration, and eventual tearing. Natural fiber geotextiles (e.g., jute, coir) are particularly vulnerable, as their organic structure decomposes rapidly under UV exposure. Synthetic geotextiles (polypropylene, polyester, polyethylene) fare better but still require additional protection to resist long-term UV damage.

Outdoor projects like highway embankments, coastal erosion control, or agricultural drainage systems expose geotextile cloth to direct sunlight for hours daily. Over months or years, unprotected geotextiles can lose 50% or more of their strength, rendering them ineffective at separation, filtration, or stabilization. This not only compromises project safety but also increases maintenance costs as materials need frequent replacement. UV resistance isn’t just a “nice-to-have” specification—it’s the foundation of a geotextile’s longevity in outdoor settings.

How Geotextiles Are Engineered for UV Resistance

Manufacturers use two primary strategies to enhance the UV resistance of geotextile cloth: material selection and UV stabilizer additives. These approaches ensure the geotextile retains its performance characteristics even after prolonged sun exposure.

1. Material Selection

The base polymer of a geotextile plays a critical role in its inherent UV resistance. Polyester (PET) is naturally more UV-resistant than polypropylene (PP), making it a preferred choice for long-term outdoor applications. Polyethylene (PE) falls between the two, with medium UV resistance. Non woven filter cloth, which is often used for drainage and sediment control, is typically made from PP or PET—with PET variants offering better longevity in sun-exposed areas. Natural fiber geotextiles, while eco-friendly, are only suitable for short-term outdoor use (6–12 months) due to their poor UV resistance.

2. UV Stabilizer Additives

Most synthetic geotextile cloth includes UV stabilizers during manufacturing. These additives (e.g., hindered amine light stabilizers, or HALS) absorb or scatter UV radiation, preventing it from breaking polymer bonds. The type and concentration of stabilizers vary by product, with higher concentrations offering longer UV protection. For example, geotextile blankets designed for permanent slope stabilization may contain premium UV stabilizers that extend their lifespan to 15–20 years, while temporary non woven filter cloth may use lower concentrations for 5–8 years of protection. Manufacturers often test UV resistance in accelerated aging chambers, simulating years of sun exposure to verify performance.

Longevity Beyond UV Resistance: Other Critical Specifications

While UV resistance is vital, geotextile cloth longevity in outdoor use depends on a combination of specifications. These traits work alongside UV protection to ensure the material withstands all outdoor stressors:

1. Tensile Strength and Abrasion Resistance

Outdoor geotextiles face mechanical stress from wind, water, soil movement, and equipment. High tensile strength ensures the material resists pulling forces without tearing, while abrasion resistance protects against damage from rocks, debris, or foot traffic. Geotextile blankets, which are often used in high-stress applications like slope stabilization, are engineered with woven or reinforced structures to enhance these properties—complementing their UV resistance for long-term durability.

2. Chemical and Biological Resistance

Outdoor environments expose geotextile cloth to chemicals (e.g., fertilizers, pesticides, saltwater) and biological activity (e.g., mold, rodents). Synthetic geotextiles are inherently resistant to most chemicals and biological degradation, unlike natural fibers. Non woven filter cloth used in coastal or agricultural projects, for example, resists saltwater corrosion and pesticide damage—ensuring it doesn’t degrade prematurely alongside UV exposure.

3. Water Permeability and Drainage

Waterlogging can weaken geotextiles over time, so permeability is critical for outdoor use. Non woven filter cloth has high porosity, allowing water to drain freely while trapping sediment. This prevents moisture buildup that could accelerate UV degradation or cause bacterial growth. Proper drainage also reduces soil pressure on the geotextile, minimizing mechanical stress and extending lifespan.

UV-Resistant Geotextiles in Action: Outdoor Applications

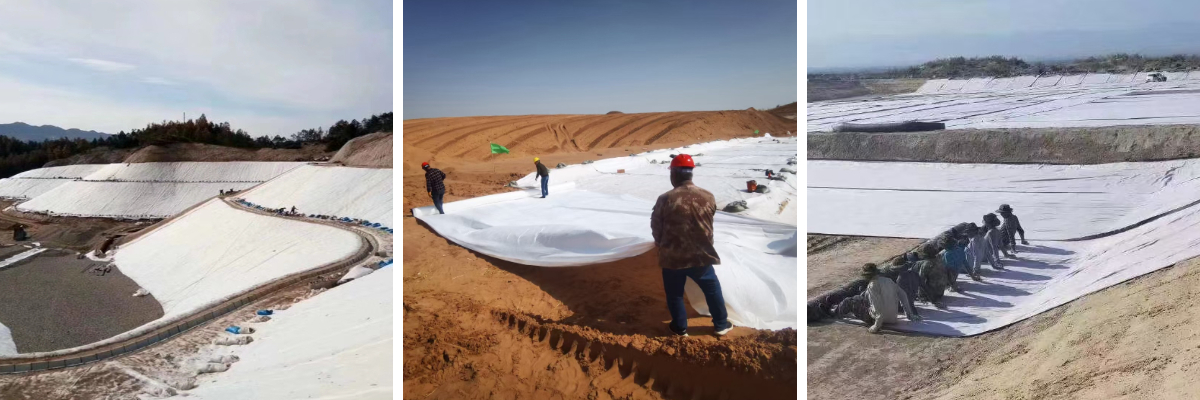

UV-resistant geotextile cloth, non woven filter cloth, and geotextile blankets are used in a range of outdoor projects where longevity is key:

1. Highway and Railway Embankments

Geotextile blankets with high UV resistance stabilize embankments, preventing soil erosion and slope failure. These blankets are exposed to direct sunlight daily, so their UV stabilizers ensure they retain strength for decades. They work alongside vegetation to create a permanent, self-sustaining stabilization system.

2. Coastal Erosion Control

Coastal projects face intense UV radiation and saltwater exposure. UV-resistant non woven filter cloth lines sand dunes or protects shorelines, filtering sediment while resisting sun damage and saltwater corrosion. Its longevity reduces the need for frequent replacements in hard-to-access coastal areas.

3. Agricultural and Landscaping

In agriculture, UV-resistant geotextile cloth acts as a weed barrier or mulch, withstanding sun exposure while suppressing weeds and retaining moisture. Landscapers use geotextile blankets for erosion control in gardens and parks, where the material must last until vegetation establishes—typically 5–10 years.

4. Mining and Industrial Sites

Mining tailings ponds and industrial waste sites require UV-resistant geotextiles to contain contaminants. Non woven filter cloth with premium UV stabilizers filters wastewater while resisting sun damage and chemical exposure, ensuring long-term containment safety.

How to Select UV-Resistant Geotextiles for Your Outdoor Project

Use these tips to choose geotextile cloth with the right UV resistance and longevity for your needs:

Check Manufacturer Specifications: Look for UV resistance ratings (e.g., “5000 hours of accelerated UV exposure” or “10-year outdoor lifespan”) and confirm the presence of UV stabilizers like HALS.

Match Material to Project Lifespan: For short-term projects (≤5 years), PP geotextiles with basic stabilizers work. For long-term projects (≥10 years), choose PET geotextiles with premium stabilizers.

Consider Application Stress: High-stress projects (coastal erosion, steep slopes) need geotextile blankets with reinforced structures and enhanced UV resistance, while low-stress projects (garden mulch) can use lighter non woven filter cloth.

Test for Local Conditions: If your project is in a sun-intense region (e.g., deserts), select geotextiles with higher UV stabilizer concentrations to account for increased radiation exposure.

Conclusion: UV Resistance = Long-Term Value

UV resistance and longevity are inseparable from successful outdoor geotextile cloth applications. Whether you’re using non woven filter cloth for drainage or geotextile blankets for slope stabilization, prioritizing these specifications ensures your material performs reliably, reduces maintenance costs, and avoids project failures.

By understanding how UV radiation impacts geotextiles, how manufacturers engineer UV resistance, and how to match products to your project’s needs, you can invest in geotextiles that stand the test of time. In outdoor construction and environmental projects, UV resistance isn’t just a specification—it’s a guarantee of long-term value, safety, and sustainability. Choose wisely, and your geotextiles will protect your project and the environment for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province