How to Test HDPE Geomembrane Quality: Laboratory and On-Site Inspection Methods

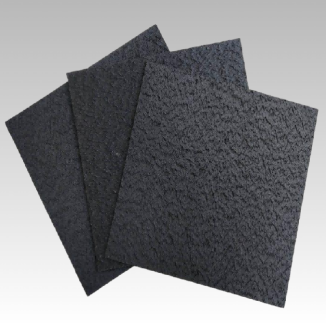

HDPE geomembrane is the spine of dependable containment and waterproofing systems—used in landfills, wastewater cure plants, agricultural ponds, and chemical storage facilities. Its overall performance at once affects undertaking safety, environmental compliance, and long-term durability. However, substandard HDPE geomembrane (e.g., skinny material, bad chemical resistance, or vulnerable structural strength) can lead to catastrophic leaks, expensive repairs, and regulatory fines. To keep away from these risks, rigorous fantastic testing—combining laboratory evaluation and on-site inspections—is non-negotiable. Below, we ruin down the most fundamental strategies to take a look at HDPE geomembrane quality, masking each managed laboratory assessments and real-world on-site checks.

1. Laboratory Basic Performance Tests for HDPE Geomembrane

Laboratory exams consider the core bodily and chemical homes of HDPE geomembrane below managed conditions. These checks verify if the cloth meets enterprise requirements (e.g., ASTM, GB/T) earlier than it’s transported to the job site.

1.1 Thickness Uniformity Test

Thickness is a foundational indicator of HDPE geomembrane quality—uneven thickness weakens the material, developing prone spots for tears or leaks. This take a look at ensures the HDPE geomembrane’s thickness fits precise necessities (e.g., 1.5mm, 2.0mm) and is regular throughout the whole roll; to habits it, pattern the geomembrane from 5–8 random areas on a roll (per ASTM D5199 standard), use a digital thickness gauge (with 22 kPa pressure, as required by means of standards) to measure every sample, then calculate the common thickness and test for deviations—most requirements permit a ±5% tolerance from the distinctive thickness. A skinny area of HDPE geomembrane is extra probable to puncture from sharp rocks or equipment, whilst overly thick areas can reason troubles for the duration of welding, making this take a look at integral for baseline quality.

1.2 Tensile Strength and Elongation Test

Tensile energy measures how tons pressure the HDPE geomembrane can face up to earlier than breaking, whilst elongation measures how an awful lot it can stretch barring tearing—both integral for withstanding soil shifts or temperature changes. This check verifies the geomembrane’s potential to withstand pulling and stretching in real-world stipulations (e.g., when underlying soil settles); the technique includes slicing the HDPE geomembrane into dog-bone-shaped specimens (per ASTM D638), mounting them in a everyday checking out computer that pulls at a regular pace (typically 50mm/min), then recording the most pressure (tensile strength, in N/mm²) and share of stretch at spoil (elongation, typically ≥100% for brilliant HDPE). Low tensile energy potential the geomembrane may additionally tear at some point of set up or use, and terrible elongation makes it susceptible to cracking in bloodless climate (when HDPE contracts), so this take a look at safeguards towards untimely failure.

1.3 Chemical Resistance Test

HDPE geomembrane regularly contacts harsh resources (e.g., wastewater chemicals, agricultural fertilizers, landfill leachate), so this take a look at ensures it won’t degrade when uncovered to these materials. It evaluates the geomembrane’s balance in opposition to project-specific chemical substances via immersing HDPE geomembrane samples in the goal chemical (e.g., 10% sulfuric acid, 5% sodium hydroxide) at a managed temperature (usually 23°C or 50°C for accelerated testing), leaving them for 7–28 days (per ASTM D543), then disposing of and checking out their tensile strength, weight, and thickness—a certified geomembrane will exhibit ≤10% alternate in tensile electricity and minimal weight/thickness loss. Chemical degradation can make the geomembrane brittle or porous, main to environment-harming leaks and regulatory violations, so this check is indispensable for compliance and longevity.

2. Laboratory Special Performance Tests for HDPE Geomembrane

Beyond fundamental properties, these exams focal point on HDPE geomembrane’s capacity to stand up to unique on-site challenges—like punctures, UV radiation, or severe temperatures.

2.1 Puncture Resistance Test

Sharp objects (e.g., rocks, roots, development debris) threaten geomembrane systems, so this check measures how properly HDPE geomembrane resists being pierced. It ensures the geomembrane can face up to unintentional contact with sharp substances in the set up base with the aid of securing a HDPE geomembrane pattern over a inflexible body (per ASTM D4833), the usage of a pointed metal probe (1.0mm tip) to push thru the pattern at 12.5mm/min, then recording the pressure required to puncture—high-quality HDPE generally wishes ≥300 N of force. A geomembrane with low puncture resistance will in all likelihood increase holes at some stage in installation, even with cautious base prep, making this take a look at key for keeping off post-installation repairs.

2.2 Weathering (UV Resistance) Test

Outdoor geomembrane structures face a long time of daylight (UV radiation), which breaks down HDPE over time, so this check simulates long-term UV publicity to verify the geomembrane retains its properties. It includes setting HDPE geomembrane samples in a xenon arc weathering chamber (per ASTM G154)—which mimics UV rays, heat, and humidity—exposing them for 1,000–3,000 hours (equivalent to 5–15 years of out of doors use), then checking out their tensile power and elongation; certified merchandise continue ≥80% of their unique strength. UV degradation makes the geomembrane brittle and crack-prone, specially in sunny regions, so skipping this check dangers untimely machine failure.

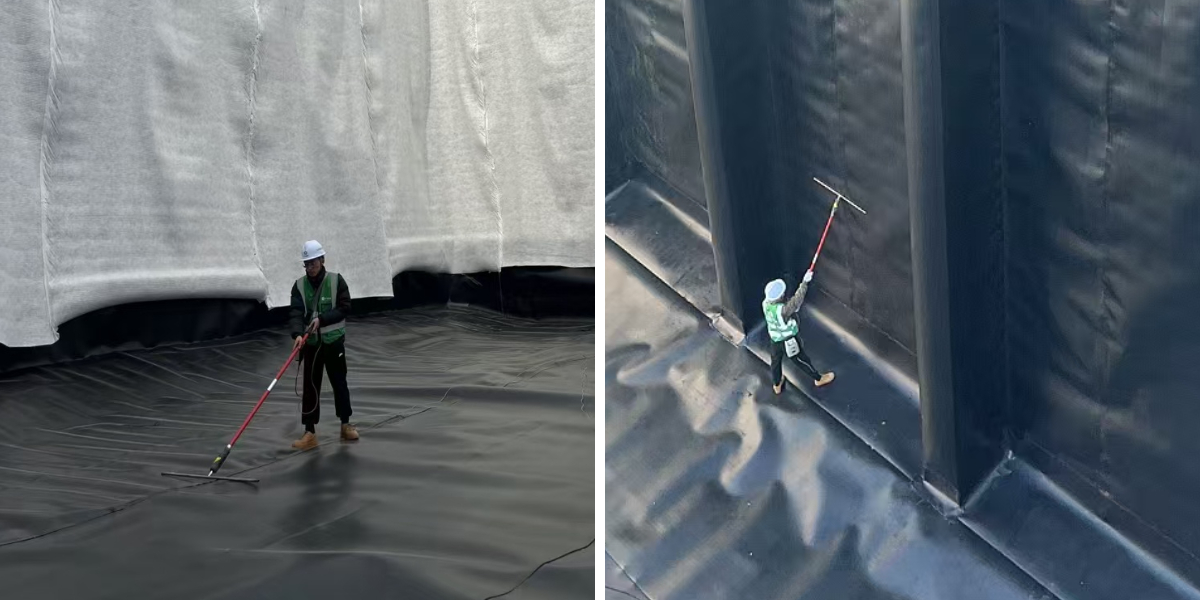

3. On-Site Visual and Dimensional Inspection of HDPE Geomembrane

Even laboratory-tested HDPE geomembrane can be broken throughout transportation or handling. On-site visible and dimensional tests are the first line of protection to seize problems earlier than installation.

3.1 Surface Defect Inspection

Visual exams pick out seen harm or flaws from transport (e.g., tears, scratches, contamination) to spot problems earlier than laying the geomembrane. To habits it, unroll the HDPE geomembrane in a clean, flat location (away from debris) and look into the complete floor for tears, holes, frayed edges (even small 1mm holes purpose leaks), discoloration (UV harm at some point of storage) or stains (chemical contamination), and bubbles/wrinkles (poor manufacturing or storage); mark faulty areas with non-toxic chalk, and reject rolls the place defects cowl extra than 5% of the surface. Installing a geomembrane with pre-existing injury wastes time and money—post-installation repairs are a ways more expensive than rejecting a inaccurate roll.

3.2 Dimensional Accuracy Check

This check verifies the HDPE geomembrane’s width and size in shape challenge specifications, making sure it suits the set up region besides immoderate reducing or overlapping (which will increase welding work and leak risks). Use a calibrated tape measure to take a look at the geomembrane’s width (at 3–4 factors alongside the roll) and complete length, then examine measurements to order specs (e.g., 6m width × 100m length)—most requirements permit ±1% tolerance for size and ±2% for width. If the geomembrane is too brief or narrow, contact the dealer immediately; delays from reordering are higher than adjusting the assignment to suit substandard material, as mismatched dimensions pressure more seams (potential leak points) or gaps that undermine the containment system.

4. On-Site Leak and Weld Quality Testing for HDPE Geomembrane

Seams (where two geomembrane panels are welded together) are the most prone phase of any system. On-site leak exams make certain these seams—and the set up geomembrane—are impermeable.

4.1 Vacuum Box Test for Welded Seams

The vacuum field take a look at is the enterprise fashionable for checking HDPE geomembrane weld integrity, detecting small leaks visible assessments miss. To operate it, easy the welded seam with a lint-free cloth, observe a soapy water answer (bubbles structure if there’s a leak), region a vacuum container (clear plastic with a seal) over the seam, create a vacuum (typically -50 kPa) with a hand pump, and preserve it for 10–15 seconds—no bubbles suggest a tight weld, whilst bubbles point out areas desiring re-welding. Weld leaks are the #1 motive of geomembrane gadget failures, and this check is obligatory for tasks like landfills and ingesting water ponds (per regulations), making it non-negotiable for gadget reliability.

4.2 Spark Test (Holiday Test) for Pinholes

This take a look at detects tiny pinholes or skinny spots in HDPE geomembrane that reason sluggish leaks, figuring out imperceptible defects past seams. Ensure the geomembrane is easy and dry, join a spark tester (low-voltage electrical tool) to a floor cable, alter voltage primarily based on thickness (e.g., 5,000V for 1.5mm HDPE, per ASTM D4788), then go the probe 2–3mm above the surface—sparks (a “holiday”) grounding to the substrate suggest a pinhole. Mark pinholes and restore with a HDPE patch earlier than proceeding; pinholes are too small to see however let water/chemicals seep over time, so this check ensures the geomembrane is one hundred percent impermeable.

Final Thoughts: Quality Testing = Long-Term Success

Cutting corners on HDPE geomembrane high-quality trying out may additionally retailer time upfront, however it leads to a long way increased fees later—from leaks and repairs to environmental fines. By combining laboratory assessments (to validate fabric properties) and on-site inspections (to trap dealing with injury and make certain suited installation), you warranty that your geomembrane machine performs as meant for 20–30 years.

Always work with suppliers who grant certified check reviews for their HDPE geomembrane, and appoint skilled inspectors to habits on-site tests. Quality is an investment, no longer an expense.

Would you like me to create a HDPE Geomembrane Quality Test Checklist that you can print and use? It will encompass laboratory take a look at requirements, on-site inspection steps, pass/fail criteria, and a guidelines for verifying provider certifications—making it convenient to make certain each roll meets your project’s standards.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province