Case Study: Using a Cement Blanket to Stabilize a Failing Pond Bank

Introduction: The Challenge of Eroding Waterfront Infrastructure

Ponds, reservoirs, and irrigation channels are vital assets in agricultural, commercial, and residential settings. However, their slopes and banks are persistently inclined to erosion from wave action, fluctuating water levels, and surface runoff. Traditional solutions like riprap or cast-in-place concrete often current significant challenges, including high cost, prolonged installation times, and ecological disruption. This case study examines a real-world project the place a rapidly deteriorating pond bank was efficiently stabilized using an advanced technology: a cement-filled geosynthetic matrix, often referred to as a cement blanket. We will discover how this solution not only solved the immediately Bund Lining crisis but also furnished a permanent, high-strength Concrete Ditch Liner equivalent surface that seamlessly integrated with the environment.

Project Background: A Pond on the Brink of Failure

The challenge was a one-acre stormwater retention pond on a commercial property. The primary problem was a 120-foot long section of the financial institution that had suffered severe erosion. Years of wave action from wind and surface water runoff had carved deep gullies into the slope, undermining the integrity of the surrounding location and threatening adjacent infrastructure.

The Original Problem Assessment:

Severe Surface Erosion: The bank face exhibited significant loss of soil, with rills and gullies up to 18 inches deep.

Underlying Soil Instability: The subsoil was once a silty-clay, which became soft and unstable when saturated, leading to sloughing.

Ineffective Previous Repairs: Attempts to restore the area with soil and seed had failed repeatedly, as the new vegetation could not set up a root hold on the rapidly eroding slope.

Urgent Need for a Permanent Solution: The property manager wanted a durable, long-term fix that could be implemented rapidly to prevent further damage and attainable liability. The client had initially considered a Concrete Ditch Liner however was deterred by the projected cost and disruption of standard forming and pouring.

Evaluating the Options: Why a Cement Blanket Was Selected

The project team evaluated several traditional methods before making a final decision.

Riprap (Rock Armor): While a frequent solution for Ditch Lining, it was deemed less suitable. The required quarry rock used to be expensive to transport and place. Furthermore, the irregular surface can be difficult to maintain, and it does now not address underlying subsurface erosion effectively.

Cast-in-Place Concrete: This would create a rigid and permanent Concrete Ditch Liner. However, the challenges had been prohibitive: the high cost of formwork, the need for concrete pump trucks, massive curing time, and the creation of a non-permeable, ecologically sterile surface that could crack with subgrade movement.

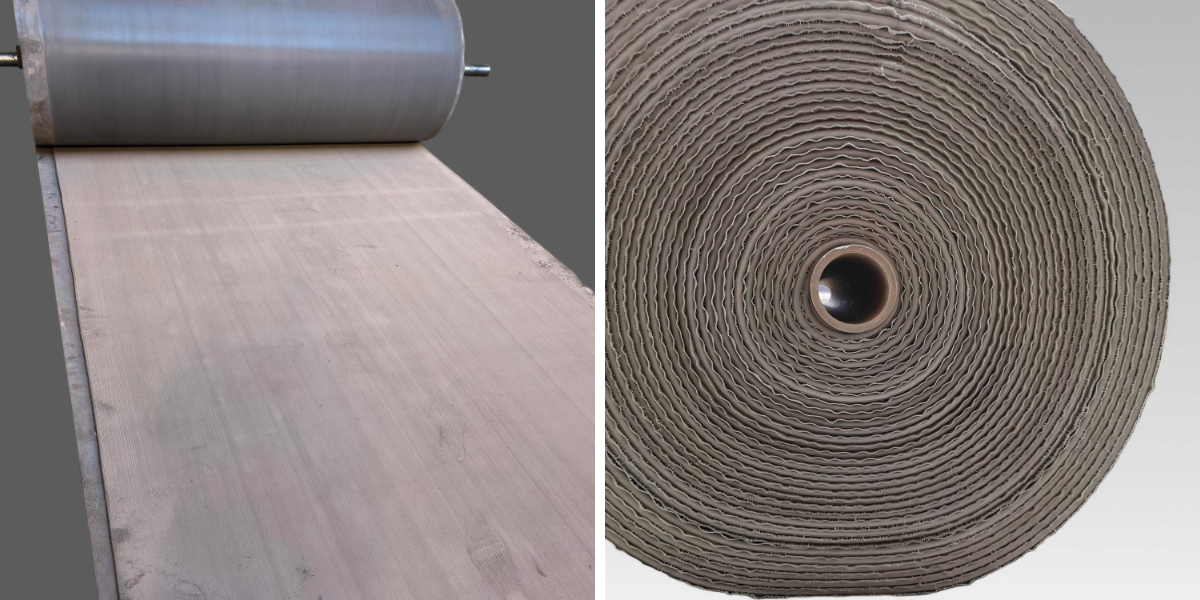

Cement Blanket System: This progressive solution emerged as the superior choice. It consists of a three-dimensional matrix of high-strength geosynthetic cloth that is deployed directly onto the prepared slope and then filled with a flowable cement slurry. The crew selected this method for its:

Rapid Deployment and Installation

Cost-Effectiveness compared to cast-in-place concrete

Flexibility and Conformability to the irregular slope

Permeability, permitting for venting of subsurface gasses and water

Ability to create a monolithic, high-strength layer perfect for both the pond bank and as a conceptual Bund Lining for containment structures.

The Solution: Step-by-Step Implementation of the Cement Blanket

The set up was completed by a skilled crew in a matter of days, a fraction of the time required for conventional methods.

Phase 1: Site Preparation

The first and most critical step used to be to regrade the severely eroded slope. The goal was to create a stable, uniform surface for the blanket to lie against. All loose, unstable soil was once removed, and the slope was cut back to its authentic design grade. The subgrade was then mechanically compacted to supply a firm, stable foundation, a crucial step for any permanent Ditch Lining or financial institution stabilization project.

Phase 2: Deployment of the Geosynthetic Matrix

The flexible, collapsed panels of the 3D geomatrix were rolled out directly onto the prepared subgrade. The fabric was easily maneuvered to conform perfectly to the contours of the slope, which include the transition at the toe and the crest. Adjacent panels were overlapped and securely fastened together, creating a continuous, seamless layer equipped to become a unified Concrete Ditch Liner system once filled.

Phase 3: Mixing and Placing the Grout

A particular mixing area was established nearby. A pumpable, flowable cement grout was once mixed in a continuous mixer. This grout was especially designed for high strength and workability. The grout was then pumped immediately from the mixer onto the deployed matrix.

Phase 4: Filling and Finishing

The crew used rakes and squeegees to systematically work the grout into the three-dimensional matrix, ensuring it was absolutely filled from bottom to top. The excess grout was once struck off, revealing the textured surface of the encapsulated fabric. This process created a uniform, in-situ Bund Lining quality floor with consistent thickness across the entire bank.

Phase 5: Curing

The cement blanket started out to cure immediately. Within just a few hours, the surface used to be firm enough to withstand rainfall. The undertaking required no wet curing or protective coverings, as the fabric matrix helps continue moisture for optimal cement hydration. The full design strength used to be achieved in 28 days, but the slope was stabilized and covered from the moment the grout had set.

Project Results and Performance Analysis

The outcome was a resounding success, assembly all the project's critical objectives.

Immediate Stabilization: Erosion was halted completely the very equal day the installation was finished. The bank used to be secure against further climate events.

Exceptional Durability: The finished cement blanket formed a monolithic, armor-like shell with a compressive strength exceeding a thousand psi, performing as a highly effective Concrete Ditch Liner. It is resistant to freeze-thaw cycles, UV degradation, and chemical exposure from the stormwater.

Cost and Time Savings: The task was completed approximately 40% quicker and at a 25% lower cost than a bid for a traditional cast-in-place concrete wall would have been.

Environmental Integration: The floor texture of the cement blanket allows for the eventual growth of a vegetative layer, enabling it to blend naturally into the panorama over time, unlike a standard Concrete Ditch Liner.

Versatility Demonstrated: This project successfully showcased the material's dual suitability for both vertical Bund Lining applications in containment and for sloped Ditch Lining and financial institution revetment.

Conclusion and Key Takeaways

This case study clearly demonstrates that a cement blanket system is a tremendously viable, efficient, and robust solution for stabilizing failing pond banks, slopes, and channels. It successfully addresses the shortcomings of riprap and cast-in-place concrete through combining speed, cost-effectiveness, and superior engineering performance.

Key Takeaways for Project Managers and Engineers:

Act Proactively: Address erosion issues early before they require big earthworks.

Consider Modern Solutions: Geosynthetic-enhanced solutions like the cement blanket offer significant blessings over traditional methods for Ditch Lining and slope armor.

Permanent Protection is Achievable: This technology offers a permanent, rigid Bund Lining and bank protection answer that is designed to last for decades with minimal maintenance.

For any site going through similar challenges with eroding banks, drainage ditches, or containment bunds, the cement blanket method warrants serious consideration. It delivers the everlasting protection of a Concrete Ditch Liner with the flexibility, speed, and economy that modern development demands.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province