A Step-by-Step Guide to Geotextile Tube Installation.

Geotextile tube set up has end up a cornerstone of modern-day engineering and environmental management. These versatile containers, crammed with slurry, provide an environment friendly and good value answer for dewatering, shoreline protection, and land reclamation. This complete information will stroll you via the whole process, from preliminary website online evaluation to closing monitoring, making sure your assignment leverages the full workable of this technology. By following hooked up geotube dewatering first-class practices, you can attain top of the linedewatering performance, structural integrity, and challenge success.

Introduction to Geotextile Tube Technology

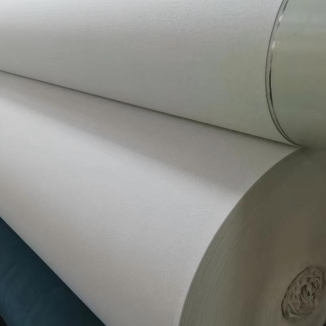

Before diving into the set up steps, it is necessary to recognize what geotextile tubes are and how they function. Essentially, a geotextile tube is a large, high-strength container made from permeable technical textiles. They are designed to be stuffed with a slurry mixture—often water-saturated sludge, sediment, or soil. The material acts as a filter, permitting easy water to break out whilst conservingthe strong particles inside. This process, acknowledged as dewatering, consequences in a vast extent discount of the contained material, developing a stable, strong structure. The use of geotextile dewatering tubes is regular in a number sectors, together with wastewater treatment, aquaculture, coastal engineering, and dredging.

Phase 1: Comprehensive Project Planning and Site Assessment

A profitable set up starts lengthy earlier than the first geotextile tube is positioned on the ground. Meticulous planning is the foundation of tremendous and secure undertaking execution.

Step 1: Conduct a Detailed Site Survey

The first motion is to absolutely investigate the set up site. Key elements to consider include:

●Topography and Ground Bearing Capacity: The floor need to be steady sufficient to help the weight of the stuffed tubes besides big settlement. Soft, unstable soils may also require a basis layer of sand or a geotextile mat.

●Tidal and Wave Action (for marine applications): Understanding water dynamics is integral for designing tube layouts that face up to hydraulic forces.

●Accessibility: Ensure that heavy machinery, transport trucks, and filling gear can effortlessly get entry to the site.

Step 2: Analyze the Filling Material

The traits of the slurry to be dewatered at once have an impact on the complete project. A consultant pattern must be examined to determine:

●Particle Size Distribution: This impacts the preference of geotextile material pore size.

●Solid Content and Chemistry: The preliminary stable proportion and the presence of chemical compounds can have an effect on dewatering pace and material selection.

●Adhering to geotube dewatering exceptional practices at this stage skill deciding on the propergeotextile fabric—one with the fantastic tensile strength, permeability, and filtration efficiency—for the precise slurry.

Step 3: Design the Tube Layout and Dimensions

Based on the web site and cloth analysis, engineers will plan the layout. This consists of figuring outthe most desirable measurement and structure of the geotextile dewatering tubes, their placement sample (e.g., stacked, single line), and the required fill volume. Proper layout ensures balance and effectivity all through the dewatering process.

Phase 2: Preparing the Installation Site

Proper web site practise is non-negotiable for the structural overall performance and durability of the installation.

Step 4: Clear and Level the Area

Remove all vegetation, rocks, debris, and any sharp objects that ought to puncture the geotextile material. The vicinity have to be graded to a smooth, degree floor to grant uniform support.

Step 5: Install a Foundation Layer

In many cases, specifically on smooth subsoils, putting in a protecting basis is a key geotube dewatering first-class practice. This commonly includes laying a non-woven geotextile material on the organized ground. This layer serves two critical functions:

It separates the underlying soil from the tube, stopping soil particles from mixing with the filling material.

It presents extra safety towards punctures from beneath and can assist with lateral drainage.

Step 6: Position and Anchor the Geotextile Tube

Unroll the empty geotextile tube onto the basis layer. Orient it in accordance to the engineered design. Anchor the tube securely in place. A frequent and tremendous approach is to use anchor trenches alongside the sides. The edges of the tube are buried in shallow trenches and backfilled with soil. This prevents the tube from transferring or sliding for the duration of the filling process, which is necessaryfor preserving the meant structure and structure.

Phase 3: The Filling and Dewatering Process

This is the core operational segment the place the geotextile dewatering tubes are activated and commence their work.

Step 7: Set Up the Filling System

The slurry is usually pumped from its supply (e.g., a dredge, containment pond) into the tube the use of a high-density polyethylene (HDPE) pipeline. A flocculant machine is frequently set up to inject polymer (flocculant) into the slurry line. This is a integral geotube dewatering satisfactory practice, as flocculants reason excellent particles to clump collectively (flocculate), dramatically accelerating the dewatering price and enhancing water clarity.

Step 8: Implement Staged Filling

Do now not fill the tube to its full peak in a single, non-stop operation. Instead, use a staged or sequential filling approach.

●First Fill Cycle: Fill the tube to a predetermined top (e.g., 50-60% of its capacity) and then cease the pump.

●Passive Dewatering: Allow the stuffed area to dewater passively. Water will drain thru the cloth walls, and the solids will consolidate. This may also take numerous hours to days, relying on the material.

●Subsequent Fill Cycles: Once widespread dewatering and consolidation have occurred, resume filling to the subsequent stage. This procedure is repeated till the remaining diagram peak is reached.

●Staged filling prevents overpressurization of the geotextile tube, which can lead to seam failure or rupture, and is a imperative fine exercise for reaching most solids retention.

Step 9: Monitor the Filling Operation Closely

Continuous monitoring for the duration of filling is essential. Operators ought to watch the pump pressure, look at the effluent water clarity, and look at the tube for any symptoms of uneven stress or workable damage. Adjustments to flocculant dosage or fill price may additionally be crucial in real-time to optimize performance.

Phase 4: Consolidation and Project Completion

The work continues after the remaining fill cycle. Proper administration of the consolidation segmentensures a secure ultimate product.

Step 10: Allow for Final Consolidation and Drying

After the ultimate filling stage, the geotextile tube must be left undisturbed for a ultimate consolidation period. This can remaining from countless weeks to months, at some stage in which inside drainage and evaporation similarly decrease the water content material and make bigger the electricity of the contained solids. The material of the geotextile dewatering tubes will progressively conform to the consolidated mass inside.

Step 11: Inspect and Manage Effluent Water

Throughout the dewatering process, the effluent water draining from the tubes ought to be managed. It ought to be clear, however if not, it might also want to be accumulated in a settling pond or recirculated. Monitoring effluent first-class is section of accountable environmental administrationand aligns with geotube dewatering pleasant practices.

Step 12: Final Inspection and Closure

Once consolidation is complete, behavior a closing inspection of the structure. The dewatered fabric inner the tubes will have a soil-like consistency and can be left in area for land formation, included with soil and vegetation, or the cloth can be slit open for elimination of the solids if the challenge requires. Proper disposal or reuse of the dewatered cloth is the ultimate step in closing out the project.

Conclusion

Installing geotextile dewatering tubes is a incredibly fantastic approach for managing difficult slurries and developing secure structures. While the method is easy in concept, its success hinges on rigorous planning, cautious execution, and a steadfast dedication to geotube dewatering nice practices. By following this step-by-step guide—from thorough web page evaluation and training to managedstaged filling and last consolidation—you can make certain your geotextile tube set up is safe, efficient, and promises the preferred environmental and engineering outcomes. Whether for dewatering sludge or constructing a new coastline, this science presents a sustainable and effective solution.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province