The Science Behind Geotextile Tubes: How They Filter Water and Retain Sediments

Geotextile tubes, in addition seen as Geotubes, are revolutionizing sediment management across industries—from coastal erosion manipulate to industrial wastewater treatment. These engineered constructions mix most superb fabric science with hydraulic engineering to attain environment excellent dewatering and sediment retention. This article delves into the scientific principles governing their performance, their purposes in Dredging and Dewatering Bags, and why they outperform ordinary methods.

1. The Core Mechanism: Filtration Through Fabric Engineering

Geotextile tubes have in notion on a dual-action process: mechanical filtration and hydrodynamic pressure to separate solids from liquids.

1.1 Fabric Composition and Pore Structure

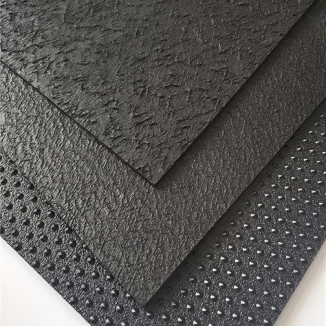

Geotubes are normally built from woven or non-woven polypropylene geotextiles, chosen for their sturdiness and permeability. The fabric’s equal opening measurement (O90)—the diameter via which 90% of particles pass—determines filtration efficiency. For instance:

Woven geotextiles (e.g., high-strength polypropylene) function smaller, uniform pores best for best sediments like silt and clay.

Non-woven geotextiles (e.g., needle-punched polyester) have irregular pore constructions suited for coarser substances like sand.

A 2025 market report highlights that woven Geotubes dominate the marine and hydraulic sector, growing at a 10% CAGR due to their superior tensile energy and resistance to wave forces.

1.2 Hydrodynamic Pressure and Consolidation

When slurry (a mix of water and sediment) is pumped into a Geotube, hydrostatic stress forces water through the cloth while conserving solids. Over time, three phases occur:

Dewatering: Water exits the tube, lowering volume with the aid of the usage of 60–90% inside hours.

Consolidation: Sediments compact under pressure, forming a secure matrix.

Drainage: Residual water percolates slowly, leaving at the once more of a dry, solid mass.

This process is accelerated via geotextile dewatering bags, which use the equal concepts on a smaller scale for site-specific applications like construction internet web site online runoff control.

2. Key Factors Influencing Performance

The efficiency of Geotubes relies upon on material properties, slurry characteristics, and operational parameters.

2.1 Fabric Strength and Durability

Geotubes ought to withstand:

Hydraulic stress during filling (up to 100 kPa for large-scale projects).

Environmental stressors like UV exposure, chemical corrosion, and abrasion.

For example, anti-UV-treated polypropylene extends lifespan in coastal applications, at the same time as high-tensile woven cloth prevent rupture during dredging operations.

2.2 Slurry Composition

The particle dimension distribution (PSD) of sediment influences filtration rate. Fine particles (e.g., clay) clog pores faster, requiring:

Pre-treatment with flocculants (e.g., polyacrylamide) to combination particles into larger clusters.

Multi-stage filtration the usage of coarser baggage upstream to shield finer Geotubes.

A 2023 research about in Geotextiles and Geomembranes verified that pre-flocculation reduces dewatering time by way of 40% in sludge treatment.

2.3 Filling Rate and Geometry

Optimal filling costs cease material deformation and make sure uniform consolidation. Engineers use finite trouble fashions (FEM) to simulate stress distribution, adjusting parameters like:

Tube diameter-to-length ratio (typically 1:5 to 1:10).

Layering method for stacked Geotubes in dike construction.

3. Applications: From Dredging to Disaster Management

Geotubes and Dredging and Dewatering Bags serve a range of sectors, pushed by way of their cost-effectiveness and environmental benefits.

3.1 Marine and Hydraulic Engineering

Coastal erosion control: Geotubes act as submerged breakwaters, absorbing wave strength and merchandising sediment deposition. In the Asia-Pacific region, where 37% of world coastlines are eroding, Geotubes are desired for their low protection in contrast to common rock revetments.

Beach restoration: Dredged sand is pumped into Geotubes to rebuild eroded shorelines. A 2025 case find out about in the Philippines validated a 60% discount in sand loss over two years the use of woven Geotubes.

3.2 Environmental Remediation

Sludge dewatering: Industrial wastewater (e.g., from mining or chemical plants) is treated with Geotubes to separate toxic sediments. Fibertex SA’s geotextile bags increased tailings dam sturdiness by means of way of 300% in South African gold mines by decreasing leachate contamination.

Oil spill response: Geotubes lined with hydrophobic fabric encompass and recover spilled oil, as examined in the 2024 Gulf of Mexico cleanup.

3.3 Construction and Mining

Dewatering luggage manage stormwater runoff on construction sites, filtering sediments to meet EPA regulations.

Mining waste management: Geotubes dewater pleasant tailings, enabling protected disposal or reuse in brick manufacturing.

4. Comparative Advantage: Why Geotubes Outperform Alternatives

Traditional methods like sandbags, concrete barriers, or sediment ponds suffer from:

High labor charges (e.g., guide sandbag filling).

Limited scalability (e.g., sediment ponds require massive land areas).

Environmental risks (e.g., concrete limitations disrupt ecosystems).

In contrast, Geotubes offer:

Cost savings: A 2024 market evaluation decided Geotube projects to be 25–40% more cost effective than traditional techniques over their 10–20-year lifespan.

Flexibility: Customizable sizes (from 1m to 50m in diameter) suit initiatives of any scale.

Sustainability: Retained sediments can be repurposed for land reclamation, lowering waste.

5. Future Innovations: Smart Geotubes and Circular Economy Integration

Research is established on enhancing Geotube overall performance through:

Smart sensors: Embedded IoT units expose pressure, moisture, and structural integrity in genuine time.

Biodegradable fabrics: Polylactic acid (PLA)-based geotextiles reduce plastic waste in transient applications.

Energy recovery: Methane generated from decomposing natural sediments in Geotubes is harnessed for electricity, as seen in Dutch wastewater therapy plants.

Conclusion: The Science Driving a Sustainable Future

Geotextile tubes, geotextile dewatering bags, and Dredging and Dewatering Bags characterize a paradigm shift in sediment management. By leveraging fabric science and hydraulic engineering, they handle world challenges like coastal erosion, industrial pollution, and neighborhood climate resilience. As the market grows (projected to achieve $3.3 billion through 2024), improvements in wise monitoring and spherical economy integration will in addition solidify their function as integral tools for a sustainable future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province