The Long-Term Performance and Durability of Geocell Materials: HDPE vs. Novel Polymers

Introduction

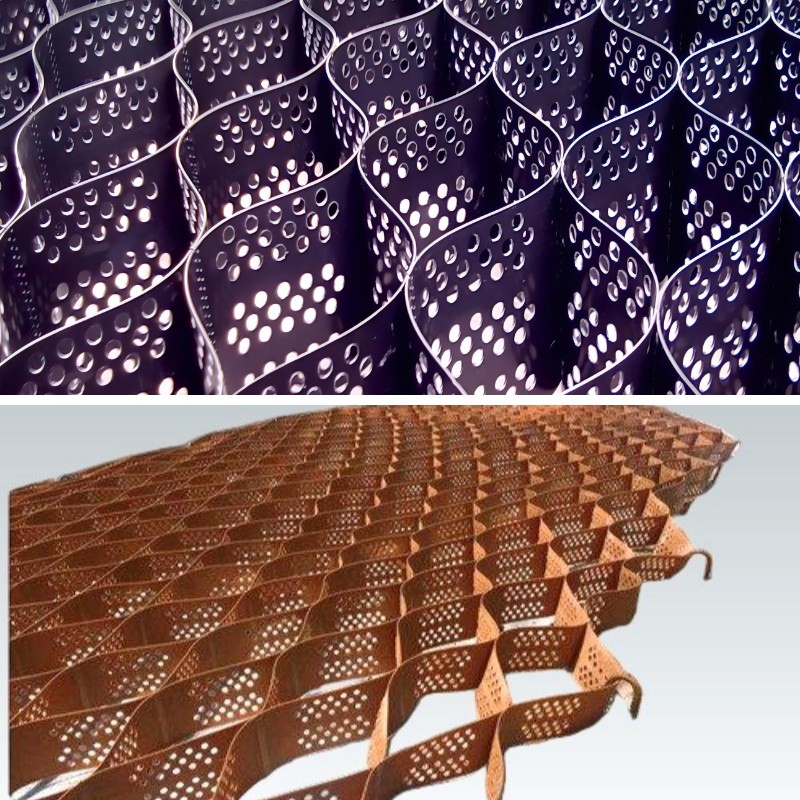

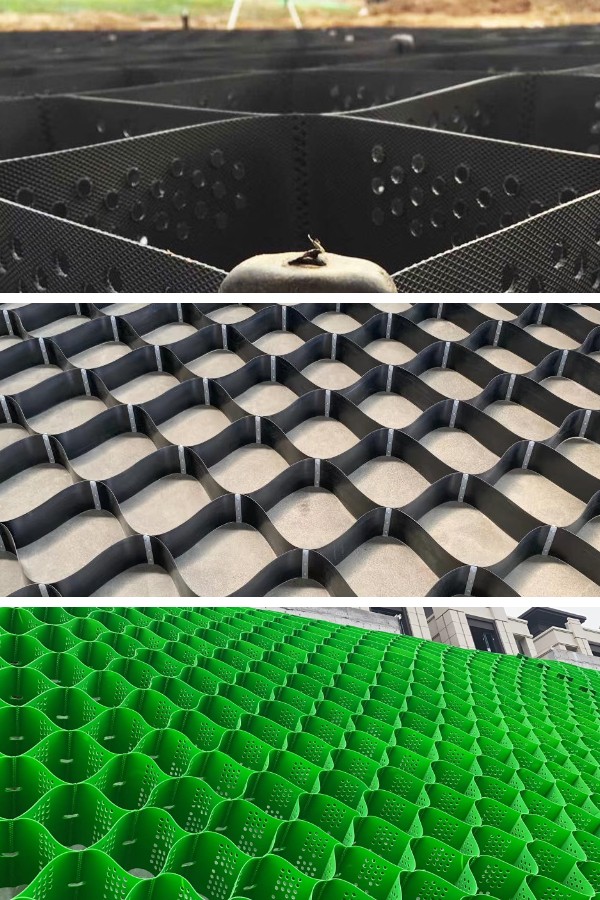

In the world of civil and geotechnical engineering, the desire of substances is paramount to the success and toughness of any project. Among the most versatile and broadly used floor stabilization options is the geocell. These three-dimensional, honeycomb-like structures, when stuffed with soil, aggregate, or concrete, create a strong composite layer that distributes masses successfully and reinforces susceptible subgrades. However, no longer all geocell substances are created equal. Their long-term overall performance and sturdiness are at once tied to the polymer from which they are manufactured. For decades, High-Density Polyethylene (HDPE) has been the enterprise standard. But current developments have added a new era of novel polymers that mission the reputation quo. This in-depth article explores the quintessential variations in the long-term sturdiness between common HDPE and these modern polymers, offering precious insights for engineers and venture managers concerned in geocell avenue base reinforcement and geocell slope stabilization.

Understanding Geocell Material Fundamentals

Before delving into the fabric showdown, it is indispensable to recognize what homes make a polymer appropriate for geocell applications. A geocell cloth is now not simply a easy plastic sheet; it is an engineering product designed to operate in harsh, frequently unpredictable environments for decades. Key residences include:

Creep Resistance: The potential to withstand long-term deformation below regular load. This is arguably the most quintessential property for geocell avenue base reinforcement, the place a everlasting load from pavement and visitors is present.

Environmental Stress Crack Resistance (ESCR): The material's resistance to cracking when subjected to tensile stresses and publicity to aggressive sellers like surfactants, oils, or chemicals.

Oxidative Stability: Resistance to degradation triggered with the aid of publicity to oxygen, regularly accelerated with the aid of warmth and UV radiation.

UV Resistance: The capability to keep residences after extended publicity to sunlight.

Chemical Resistance: Performance balance when in contact with soils, leachates, salts, and different chemical compounds current in the challenge environment.

The desire of geocell fabric without delay influences the layout lifestyles and protection cycles of initiatives ranging from heavy-haul roadways to fundamental geocell slope stabilization efforts.

HDPE: The Established Workhorse

High-Density Polyethylene (HDPE) has been the dominant geocell cloth for years, and for right reason. Its great adoption is constructed on a tested music document and a set of well-understood characteristics.

Strengths of HDPE Geocells

HDPE provides superb chemical resistance, making it pretty long lasting in a large vary of soil conditions, such as acidic and alkaline environments. This is a full-size benefit for functions like landfill liners and containment partitions the place chemical publicity is expected. Furthermore, HDPE offers proper UV resistance when desirable stabilized with carbon black, which protects the polymer chains from photo voltaic radiation. Its flexibility permits it to accommodate some differential agreement besides catastrophic failure, a treasured trait in many floor enchancment scenarios. For many fashionable applications, HDPE has furnished a dependable and comparatively cheap answer for geocell slope stabilization and get entry to street construction.

Long-Term Limitations and Vulnerabilities

Despite its strengths, HDPE has inherent vulnerabilities that can influence its long-term performance. The most sizable of these is creep. HDPE is a semi-crystalline polymer that, underneath sustained load, can slowly and constantly deform over time. This is a necessary consideration for everlasting geocell street base reinforcement beneath paved roads, as immoderate creep can lead to rutting and pavement failure.

The 2nd predominant vulnerability is its decrease resistance to Environmental Stress Cracking (ESC). While HDPE is chemically resistant to a extensive spectrum of substances, it is inclined to cracking below stress when uncovered to sure polar retailers like surfactants (found in soaps and detergents) and some oxidizing acids. In functions the place such dealers are present—for instance, in city environments or industrial sites—this can lead to untimely brittle failure of the geocell material. This vulnerability necessitates cautious consideration of the project's precise surroundings earlier than choosing HDPE for a integral geocell slope stabilization project.

The Rise of Novel Polymers: A New Generation of Performance

Driven by way of the want for greater overall performance in annoying applications, polymer science has delivered a new classification of substances mainly engineered to overcome the boundaries of HDPE. These novel polymers, which consist of superior formulations and copolymers, are redefining the benchmarks for geocell durability.

Enhanced Properties for Demanding Applications

The major gain of these novel polymers lies in their notably elevated mechanical properties. They showcase distinctly excessive creep resistance, frequently an order of magnitude higher than trendy HDPE. This makes them the top of the line desire for high-load, everlasting purposes like geocell street base reinforcement for highways, port terminals, and railway embankments, the place long-term dimensional balance is non-negotiable.

Furthermore, these superior substances boast an magnificent Environmental Stress Crack Resistance (ESCR). They are inherently resistant to a tons wider vary of stress-cracking agents, notably decreasing the chance of brittle failure in chemically difficult environments. This more advantageous sturdiness ensures the long-term integrity of structures, whether or not it is a bolstered slope at the back of a protecting wall or a channel lining. For engineers, this multiplied chemical compatibility offers a larger protection margin and reduces assignment risk.

Long-Term Durability and Sustainability

The long-term advantages of novel polymer geocell substances prolong past simply creep and ESCR. Their improved molecular shape regularly affords foremost durability and affect resistance, which is really helpful at some stage in set up and when subjected to dynamic loads. From a lifecycle perspective, the prolonged provider lifestyles and decreased threat of failure make contributions to a greater sustainable answer by means of minimizing aid consumption for repairs and reconstruction. When designing a geocell slope stabilization gadget for a quintessential infrastructure project, such as a toll road reduce or an embankment close to a waterway, the long-term integrity provided by using these superior polymers can be a decisive factor.

Head-to-Head Comparison: Key Factors for Material Selection

Choosing between HDPE and a novel polymer geocell cloth is now not about discovering a universally "better" option, however instead figuring out the proper device for the job. The choice ought to be guided by means of a clear perception of the project's precise requirements.

Project-Specific Application Analysis

For Heavy-Load, Permanent Infrastructure (Geocell Road Base Reinforcement): In purposes involving high, sustained loads, such as underneath paved roads, industrial yards, or airport runways, the most excellent creep resistance of novel polymers makes them the unequivocal choice. The long-term deformation of HDPE underneath these stipulations can be a design-limiting factor, whereas novel polymers make certain the structural integrity of the pavement machine for its whole layout life.

For Chemically Challenging Environments: If the mission website online has a manageable for infection from oils, surfactants, industrial chemicals, or aggressive leachates, the excessive ESCR of novel polymers is essential. Using HDPE in such environments introduces an useless threat of stress cracking. This is necessary for geocell slope stabilization in industrial areas, mining operations, or waste containment facilities.

For Standard and Temporary Applications: For transient get admission to roads, much less crucial slope protection, or tasks with minimal long-term loading and no chemical exposure, HDPE stays a doable and frequently greater cost-efficient option. Its verified records and vast availability make it a smart preference for these lower-risk scenarios.

Cost Considerations and Lifecycle Value

While the preliminary buy charge of novel polymer geocells may additionally be greater than that of HDPE, a easy cost-based evaluation is misleading. A real contrast need to be primarily based on lifecycle cost. The more desirable durability, decreased creep, and most appropriate environmental resistance of novel polymers translate into:

Reduced long-term maintenance.

Lower danger of untimely failure and highly-priced repairs.

Extended provider lifestyles for the project.

For everlasting infrastructure, the place the value of failure is immense, the preliminary funding in a top rate geocell fabric is without problems justified by way of the long-term financial savings and danger mitigation.

Conclusion: Making an Informed Choice for Your Project

The evolution of geocell substances from trendy HDPE to superior novel polymers represents a widespread bounce ahead in geotechnical engineering. HDPE continues to be a dependable cloth for many purposes the place its residences are sufficient. However, for tasks stressful the best requirements of long-term performance, the obstacles of HDPE in creep and environmental stress cracking can't be overlooked.

Novel polymers, with their engineered molecular structures, immediately tackle these weaknesses, imparting unparalleled sturdiness for the most difficult conditions. Whether you are designing a fundamental geocell avenue base reinforcement machine that ought to stand up to many years of heavy site visitors or a geocell slope stabilization assignment in a chemically aggressive environment, these superior substances grant the self assurance and overall performance required for success.

The key to most useful assignment consequences lies in a thorough site-specific analysis. By cautiously evaluating the long-term loads, environmental exposures, and overall performance expectations, engineers can make an knowledgeable selection on the most appropriate geocell material, making sure that their buildings are now not solely constructed to final however are additionally low-budget over their whole lifecycle.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province