Solving the Puncture Problem: How Composite Geomembranes Offer Superior Protection

Introduction: The Critical Need for Impermeable Barriers

In the world of civil and environmental engineering, the integrity of a containment barrier is everything. Whether defending groundwater from contamination, making sure the balance of a water reservoir, or securing a landfill cell, a single breach can lead to catastrophic environmental and monetary consequences. For decades, the main line of protection has been the geomembrane—a thin, impermeable sheet. However, general geomembranes face a power and ambitious enemy: puncture. This article delves into the science and finest overall performance of the Composite Geo-membrane, a sturdy engineered answer in particular designed to overcome this vulnerability and furnish unparalleled, long-lasting protection.

The Achilles' Heel: Understanding the Puncture Vulnerability

A standard, single-textured geomembrane, whilst noticeably impermeable, is prone to harm from a range of sources. This puncture vulnerability is now not basically a theoretical risk; it is a frequent motive of liner failure. The threats are severa and frequently hidden inside the very substances intended to guide the structure.

Sharp Aggregates: The subgrade soil or the shielding cowl soil can comprise sharp rocks and debris. Under the large load of overlying waste or water, these particles can press in opposition to and subsequently pierce a standalone geomembrane.

Construction Activities: The set up manner itself is a high-risk period. Worker traffic, tools movement, and the placement of drainage geonets or different substances can by accident tear or puncture the liner.

Differential Settlement: As the floor underneath a liner settles unevenly, it can stretch and stress the geomembrane, making it greater prone to stress cracking and puncture from protruding objects.

In functions like landfill lining, the place the penalties of failure are severe, this vulnerability is unacceptable. A Landfill Composite Geomembrane is now not a luxury; it is a necessity to mitigate these ever-present risks.

What is a Composite Geomembrane? A Synergistic Design

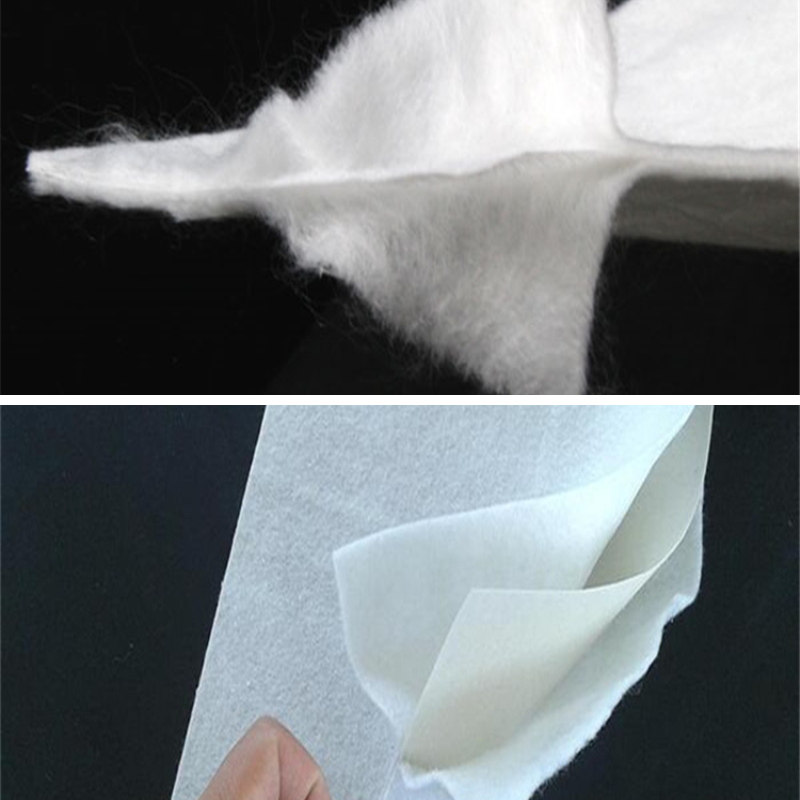

A Composite Geo-membrane is no longer a new, homogenous material. Instead, it is a brilliantly engineered laminate that combines the strengths of two awesome geosynthetics: a long lasting geomembrane and a sturdy nonwoven geotextile. The geomembrane, usually made from substances like HDPE, affords the imperative feature of hydraulic impermeability. The geotextile component, needled-punched to create a dense fibrous structure, acts as a sacrificial cushion and a sturdy reinforcement layer.

The key to its overall performance lies in the synergy between these layers. They are factory-bonded, both via thermal lamination or needle-punching, to create a single, built-in product. This union creates a machine the place the entire is appreciably larger than the sum of its parts. The geotextile does now not simply take a seat on the geomembrane; it actively protects it, distributing factor masses and absorbing have an impact on power that would in any other case be targeted on a single factor of the impermeable layer.

The Mechanics of Protection: How the Geotextile Acts as a Cushion

The shielding mechanism of a Composite Geo-membrane is each easy and quite effective. Imagine urgent a sharp nail in opposition to a single sheet of plastic versus urgent it in opposition to a thick stack of felt. The plastic sheet will puncture easily, whilst the felt will soak up the force, permitting the fibers to rearrange round the nail and distribute the stress over a wider area. This is exactly the position of the geotextile in the composite structure.

When a sharp object, like a stone in the subgrade or drainage gravel, presses towards the composite, the geotextile dealing with the danger is the first line of defense. Its dense, tangled net of artificial fibers:

Absorbs and Dissipates Energy: The fibrous structure compresses and deforms, absorbing the kinetic power of the have an impact on or sustained load.

Distributes Point Loads: The pressure that would be a pinpoint on a wellknown geomembrane is unfold out over a a great deal large floor vicinity of the underlying geomembrane.

Provides a Cushioning Barrier: The geotextile bodily prevents the sharp object from making direct, high-pressure contact with the impermeable geomembrane layer.

This multi-faceted defensive motion is what makes a Composite Geo-membrane tremendously resistant to puncture, even in the most worrying environments like a Landfill Composite Geomembrane machine the place waste agreement creates dynamic, unpredictable loads.

Key Advantages Beyond Puncture Resistance

While fixing the puncture hassle is its most important feat, the Composite Geo-membrane gives a suite of extra advantages that decorate basic venture overall performance and longevity.

Enhanced Interface Friction: The textured floor of the geotextile presents drastically greater friction angles towards each soils and different geosynthetics (like geonets or different geotextile layers). This is fundamental for slope stability, stopping the liner gadget from sliding below its very own weight or the weight of overlying materials. This is a fundamental attribute for any sloped containment structure.

Increased Tensile Strength and Durability: The lamination of the geotextile to the geomembrane adds tremendous tensile energy to the composite product. This makes it greater resistant to set up stresses and long-term anxiety from subgrade settlement. The ruggedness of a Composite Geo-membrane frequently permits for the use of a thinner geomembrane layer besides sacrificing performance, presenting practicable value savings.

Protection from UV Degradation: During the set up and building phase, the geotextile layer can assist guard the underlying geomembrane from direct ultraviolet (UV) radiation, which can degrade and embrittle polymers over time. This is a quintessential consideration for any venture with prolonged publicity timelines earlier than remaining cowl is placed, a frequent state of affairs in landfill construction.

Critical Applications: Where Composite Geomembranes are Non-Negotiable

The gold standard homes of composite geomembranes make them the fabric of desire for functions the place failure is now not an option. Their use is a best-practice wellknown in quite a few high-stakes fields.

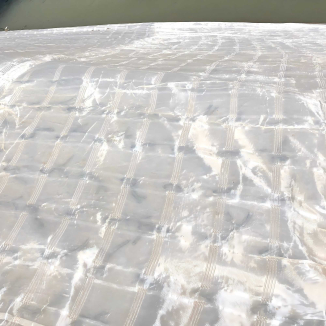

Landfill Liners and Caps: This is the quintessential application. A Landfill Composite Geomembrane is used in the base liner device to incorporate leachate and in the ultimate cap to forestall water infiltration. The harsh environment, with sharp waste substances and heavy equipment, needs the puncture resistance and delivered power the composite provides.

Mining and Heap Leach Pads: In mining, leach pads are used to extract metals from ore the use of chemical solutions. The liners for these pads ought to stand up to the weight of large ore piles and withstand puncture whilst containing aggressive chemical solutions. A Composite Geo-membrane is ideally ideal for this twin challenge.

Water and Liquid Containment: Reservoirs, evaporation ponds, and firewater retention basins gain from the brought protection, in particular on variable subgrades the place sharp rocks may additionally be present. The more suitable slope steadiness supplied by using the textured geotextile is additionally a principal gain for steep-sided reservoirs.

Environmental Remediation Projects: Sites contaminated with hazardous waste require the most dependable containment structures to stop the unfold of pollutants. The redundancy and robustness of a composite device grant the excessive security thing required for such touchy projects.

Installation and Cost-Benefit Considerations

The set up of a Composite Geo-membrane follows comparable ideas to that of a widespread geomembrane, with cautious interest to scanning and anchorage. The introduced thickness and weight of the geotextile layer require barely extra labor however end result in a extra sturdy and forgiving product at some point of installation. The geotextile itself helps to bridge small voids or imperfections in the subgrade, supplying an extra layer of protection.

From a fee perspective, a Composite Geo-membrane has a greater preliminary fabric value than a standalone geomembrane of equal thickness. However, this view is shortsighted. A genuine assessment ought to be primarily based on lifecycle cost. The dramatic discount in the chance of puncture failure interprets into:

Lower danger of catastrophic environmental illness and related multi-million greenback cleanup liabilities.

Reduced want for pleasant assurance repairs at some point of construction.

Extended provider existence and decreased long-term maintenance.

For any venture the place the fee of failure is high, the preliminary funding in a Composite Geo-membrane is no longer an cost however a shape of high-return insurance.

Conclusion: Investing in Long-Term Integrity and Peace of Mind

The puncture hassle is a integral mission that has plagued containment initiatives for years. While popular geomembranes grant the barrier, they lack the inherent armor to live to tell the tale in a harsh, real-world environment. The Composite Geo-membrane is the engineered answer to this indispensable issue. By intelligently combining a resilient geotextile with an impermeable geomembrane, it creates a synergistic device that presents ideal puncture protection, greater stability, and unparalleled durability.

When specifying a lining gadget for a landfill, a mining operation, or any imperative containment project, opting for a standalone geomembrane introduces a huge and pointless risk. Choosing a Composite Geo-membrane, mainly a Landfill Composite Geomembrane for the most traumatic applications, is an funding in the long-term integrity of the project, the safety of the surrounding environment, and closing peace of mind. It is the definitive reply to fixing the puncture trouble as soon as and for all.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province