How Do Geotubes Work? The Science of Dewatering with Geosynthetic Containers

Introduction: Turning Liquid Waste into Manageable Solids

Across industries like dredging, mining, and wastewater treatment, a frequent and high-priced undertaking persists: managing giant volumes of water-saturated sludge or slurry. Transporting and disposing of this material, which can be over 90% water, is logistically and financially burdensome. This is the place geosynthetic tubes—also acknowledged as Dredging and Dewatering Bags—offer an elegant, engineered solution. More than just easy bags, they are a dewatering technological know-how that leverages concepts of physics, geotextile science, and chemistry to effectively separate solids from liquids. This article demystifies the science in the back of how these containers work, remodeling difficult slurry into stable, stable cake for disposal or reuse, with functions extending to progressive Flood Control Geotube systems.

The Core Components: Engineered Fabric and Strategic Chemistry

A Geotube gadget consists of two key elements:

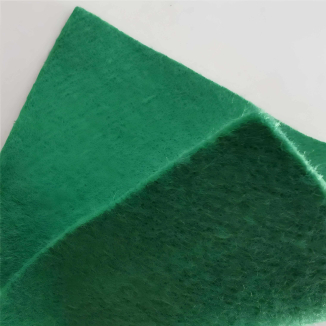

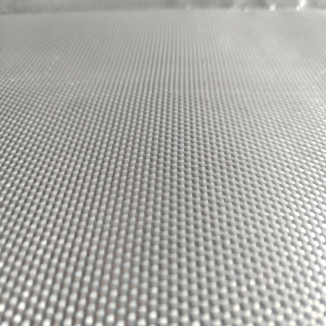

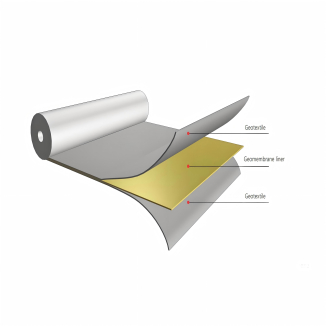

The Geosynthetic Container: These are large, seamless tubes or containers manufactured from high-strength, engineered geotextiles. The cloth is no longer a easy barrier; it is a precision filter. It is woven or non-woven with particularly calibrated pore sizes—small adequate to hold exceptional strong particles however porous sufficient to enable water molecules to get away freely underneath pressure. The fabric ought to additionally possess superb tensile energy to face up to the mammoth interior pressures at some point of filling.

Polymeric Flocculants: Before slurry is pumped into the tubes, it is conditioned with chemical polymers. These long-chain molecules act as bridges, binding tiny, suspended stable particles (like clays and silts) into larger, cohesive clumps known as “flocs.” This process, known as flocculation, is critical. It transforms the slurry from a secure suspension of best particles into a series of large aggregates that will easily launch water and be efficiently retained by way of the geotextile filter.

The Four-Stage Scientific Process

The dewatering technique is a non-stop cycle of filling, draining, and consolidating, pushed via herbal forces and clever engineering.

Stage 1: Conditioning and Filling

The slurry, such as dredged sediment or industrial waste, is first combined with the greatest dose of polymer in a mixing unit. As the flocs form, the conditioned slurry is pumped into the geosynthetic tubes. The filling manner is generally achieved in managed cycles to enable for fine dewatering between fills.

Stage 2: Filtration and Effluent Release (The Key Science)

This is the place the core dewatering occurs. As the tube fills, the hydraulic head (the stress created by way of the peak of the slurry column inside) forces the free water in the slurry in opposition to the tube walls. The engineered geotextile acts as a filter:

Retention: The large flocs and stable particles are bodily retained inner the tube, forming a filter cake alongside the fabric's internal surface.

Release: Clean effluent water passively drains via the microscopic pores of the material and is gathered for protected discharge or recycling.

This is a gravity-driven, low-energy filtration process. The geotextile’s pore shape is designed to stop blinding (clogging), making sure steady water launch over time.

Stage 3: Consolidation and Volume Reduction

Once pumping stops, the system continues. The weight of the amassed solids exerts stress on the decrease layers, forcing out extra pore water. This phase, referred to as consolidation, can proceed for weeks, notably growing the solids content material and lowering the quantity of the contained material—often through 50% to 90%. What started out as a liquid slurry is now a solid, stackable material.

Stage 4: Curing and Final Disposition

The dewatered solids proceed to dry and strengthen, a procedure aided through evaporation if the tubes are exposed. Finally, the geotextile pores and skin is reduce away (or left in vicinity for some applications), revealing a secure strong mass geared up for landfill disposal, recommended reuse, or on-site capping.

Diverse Applications of the Technology

The science is universally relevant to any water-borne solids:

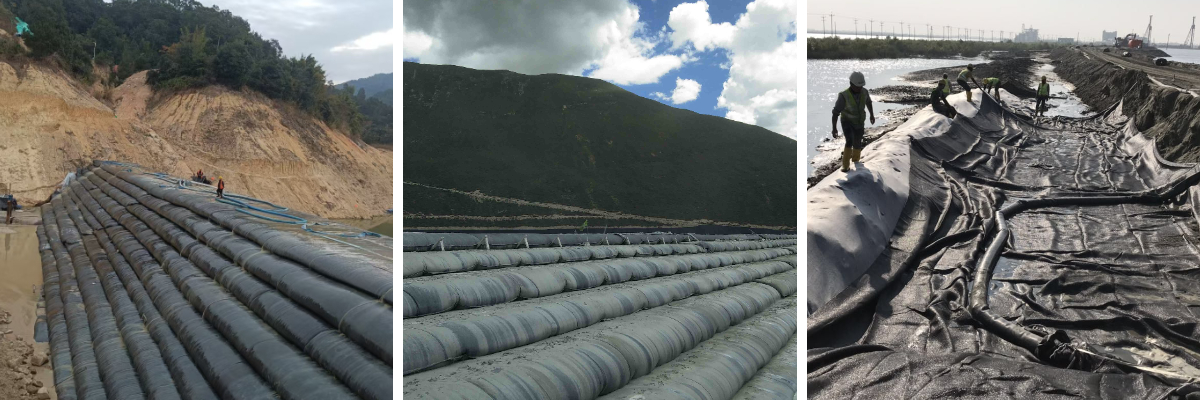

Dredging and Dewatering Bags: This is the most frequent application. Sediment dredged from harbors, rivers, or ponds is pumped immediately into the tubes onshore or on a barge. This eliminates the want for large, open containment areas and approves for rapid, on-site processing of contaminated or easy sediments.

Industrial and Municipal Sludge Treatment: Wastewater remedy flora use geosynthetic tubes to dewater biosolids, decreasing hauling charges and developing a product appropriate for composting or land application.

Mining and Tailings Management: Mineral processing slurries and tailings are dewatered to get better manner water and create a extra steady dry stack for disposal, enhancing environmental safety.

Flood Control and Emergency Barriers: As Flood Control Geotube systems, empty tubes can be unexpectedly deployed and crammed with neighborhood sand or water to create instant, bendy boundaries in opposition to rising water, storm surges, or erosion. Their permeable nature additionally helps control seepage pressure.

Advantages Over Traditional Methods

Understanding the science displays the operational benefits:

Cost-Effectiveness: Dramatically reduces transportation and disposal fees by using disposing of water volume.

Efficiency and Simplicity: A passive, low-energy system requiring minimal infrastructure in contrast to mechanical presses or centrifuges.

Versatility and Mobility: Systems can be set up nearly somewhere and scaled to task size.

Environmental Safety: Provides closed-container processing for contaminated materials, stopping release of pollutants. Clean effluent can be recycled.

Conclusion: A Synergy of Simplicity and Engineering

Geotubes work thru a effective synergy of fabric science and necessary physics. The engineered geotextile offers a selective filter, whilst polymer chemistry prepares the solids for environment friendly capture. Together, beneath the easy pressure of gravity and hydraulic pressure, they operate a non-stop solid-liquid separation. Whether deployed as general Dredging and Dewatering Bags for environmental cleanup or as an emergency Flood Control Geotube barrier, the underlying science stays the same: an intelligent, efficient, and sustainable approach to manipulate the world’s slurry and sediment challenges. For assignment managers and engineers, it represents a pass from costly, energy-intensive dealing with to a smarter, gravity-assisted solution.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province