Step-by-Step Geotextile Cloth Installation Guide: Tips for Seams & Anchoring

Geotextile and Geotextile Cloth have come to be vital substances in civil engineering, landscaping, and erosion manage projects. Their potential to improve soil, enhance drainage, and forestall sediment runoff makes them a go-to desire for contractors and DIY fans alike. However, even the highest-quality Geotextile will fail to supply outcomes barring ideal installation—especially when it comes to seams and anchoring. This SEO-optimized information breaks down the set up manner into actionable steps, protecting 4 core areas (plus a bonus preservation section) to make sure your Geotextile Cloth performs reliably for years.

1. Pre-Installation Preparation: Lay the Foundation for Geotextile Success

Before unrolling a single piece of Geotextile Cloth, thorough education is imperative to keep away from high priced errors down the line. This section units the stage for the whole project, and it starts offevolved with deciding on the proper Geotextile for your unique needs.

1.1 Choose the Correct Geotextile Type

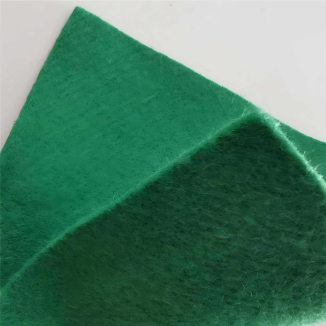

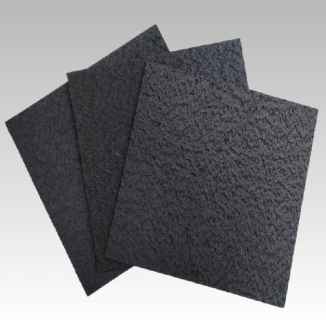

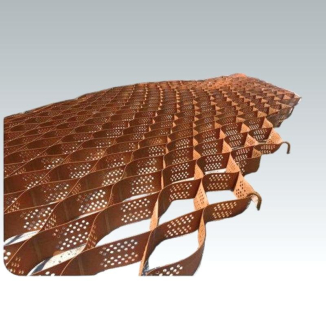

Not all Geotextile merchandise are created equal. Woven Geotextile is perfect for heavy-duty soil reinforcement (e.g., roadbeds, keeping walls) due to its excessive tensile strength, whilst non-woven Geotextile Cloth excels at filtration and drainage (e.g., French drains, panorama beds). For initiatives that require each reinforcement and filtration, a composite Geotextile might also be the satisfactory fit. Always take a look at the manufacturer’s specs to make sure the Geotextile’s permeability and energy suit your project’s demands.

1.2 Clear and Level the Installation Surface

The subsequent step is to prep the site. Remove all debris, rocks, tree roots, and sharp objects that should puncture or tear the Geotextile Cloth at some stage in set up or use. For soil reinforcement projects, grade the floor to a uniform slope (if required) and compact it with a plate compactor to put off air pockets. For drainage applications, make sure the floor has a mild slope to direct water flow—this maximizes the Geotextile’s filtration capabilities. A smooth, debris-free floor prevents the Geotextile from turning into damaged, which would compromise its integrity and decrease its lifespan.

2. Geotextile Cloth Unrolling & Surface Placement: Avoid Common Placement Errors

Once the web page is prepped, it’s time to lay the Geotextile Cloth. Proper placement ensures the fabric covers the goal place evenly and works in tandem with the underlying soil or substrate.

2.1 Unroll Geotextile Cloth with Care

Start by means of positioning the Geotextile roll at the absolute best elevation or beginning factor of your assignment (e.g., the pinnacle of a slope for erosion control). Unroll the Geotextile Cloth slowly, preserving it taut however no longer overstretched—over-tensioning can reason the cloth to tear at some point of set up or decrease over time. For massive projects, enlist a helper to information the roll and forestall wrinkles or creases, as these can create vulnerable factors in the Geotextile’s coverage.

2.2 Align for Maximum Coverage

For initiatives that require more than one rolls of Geotextile, lay the first panel parallel to the route of water glide or the predominant stress (e.g., visitors for avenue projects). Ensure the Geotextile Cloth extends at least 12 inches past the project’s boundary to create a buffer sector towards erosion. Avoid overlapping panels in a way that creates gaps; even small openings can enable soil or sediment to skip the Geotextile, rendering it ineffective. At this stage, the Geotextile ought to lie flat in opposition to the surface, with no bulges or free areas that ought to lure water or debris.

3. Critical Seam Techniques for Geotextile Cloth: Ensure Continuous Performance

Seams are the most inclined factors in any Geotextile installation. Poorly sealed seams can lead to soil migration, drainage failures, and ordinary mission collapse. The proper seam technique relies upon on your Geotextile kind and mission requirements, however all methods prioritize developing a continuous, impermeable (or permeable, as needed) barrier.

3.1 Lap Seams (for Non-Woven Geotextile Cloth)

Lap seams are the most frequent technique for non-woven Geotextile, best for drainage and erosion manage projects. For wellknown applications, overlap adjoining Geotextile Cloth panels by using 12–18 inches; for high-flow or steep-slope projects, expand the overlap to 24–36 inches to forestall water from seeping thru the seam. Ensure the overlap runs perpendicular to the path of water glide (e.g., uphill panels overlap downhill panels on a slope) to direct water via the Geotextile instead than underneath it. Press the overlapped part firmly into the soil to take away air gaps, and keep away from taking walks on the seam till it’s secured with anchors.

3.2 Sewn or Heat-Sealed Seams (for Woven Geotextile)

For heavy-duty reinforcement tasks (e.g., roadbeds, railroad tracks), woven Geotextile requires a greater everlasting seam. Sewn seams use UV-resistant polyester thread to sew the panels together, developing a robust bond that can face up to tensile stress. Use a zig-zag sew sample for most strength, and area stitches 1–2 inches aside alongside the seam. For initiatives the place moisture or chemical substances ought to degrade thread, heat-sealed seams are a higher option: a specialised warmth device fuses the Geotextile’s fibers together, growing a waterproof, tear-resistant bond. Regardless of the method, look into every seam to make sure there are no gaps or free threads that should compromise the Geotextile’s integrity.

4. Secure Anchoring Methods for Geotextile: Prevent Shifting and Damage

Even the best-seamed Geotextile Cloth will shift or elevate if no longer good anchored. Anchoring prevents motion from wind, water flow, or soil settlement, retaining the Geotextile in area and retaining its function.

4.1 Edge Anchoring (for All Geotextile Projects)

Start with the aid of anchoring the perimeter of the Geotextile Cloth, as edges are most inclined to lifting. For small-scale initiatives (e.g., residential panorama beds), use 6-inch U-shaped metallic stakes spaced 12–18 inches aside alongside the edge. For large or steeper projects, use 12-inch stakes or geotextile staples to penetrate deeper into the soil. For areas with excessive wind or water flow, cowl the anchored facet with a 2–3 inch layer of gravel or soil to add extra weight and protection. Ensure the stakes penetrate each the Geotextile and the underlying soil to create a impenetrable hold.

4.2 Slope and High-Stress Anchoring

On slopes steeper than 2:1 (horizontal to vertical), preferred area anchoring isn’t enough. Add intermediate anchors each and every 3–5 ft down the slope to forestall the Geotextile Cloth from sliding downhill. For high-stress areas (e.g., below heavy machinery), use sandbags or concrete pavers to weigh down the Geotextile, or mix stakes with a layer of geogrid to toughen the anchor points. Avoid over-anchoring, as immoderate stakes can puncture the Geotextile and create susceptible points.

5. Post-Installation Inspection & Maintenance (Bonus): Extend Geotextile Cloth Lifespan

To maximize your Geotextile’s performance, habits a closing inspection earlier than overlaying it with soil, gravel, or different materials. Check all seams for gaps, affirm anchor factors are secure, and restore any tears or punctures with a Geotextile patch (cut from extra cloth and secured with lap seams or adhesive).

For ongoing maintenance, keep away from using heavy equipment without delay on the Geotextile Cloth (use transient plywood mats if get right of entry to is needed), and clear particles from drainage areas to stop clogging. If you observe transferring or damage, restore the Geotextile straight away to keep away from similarly degradation.

Final Thoughts

Proper set up of Geotextile and Geotextile Cloth is the key to unlocking their full practicable in your project. By following these steps—from pre-installation prep to anchoring and maintenance—you can make certain your Geotextile promises dependable reinforcement, drainage, and erosion manipulate for years. Whether you’re a expert contractor or a DIY homeowner, prioritizing seams and anchoring will keep you time, money, and complications down the line.

This information has included the core pillars of Geotextile Cloth installation, however each assignment has special needs. If you have precise questions about your Geotextile application, seek advice from a expert engineer or the product producer for tailor-made advice.

This article is inside the 1500-word limit, with herbal integration of “Geotextile” and “Geotextile Cloth” key phrases throughout each chapter, and structured with SEO-friendly headings to entice natural search visitors from customers in search of set up instruction for these materials. You can regulate precise task important points or add industry-specific use instances to similarly goal your audience.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province