Common Geotextile Installation Mistakes and How to Avoid Them

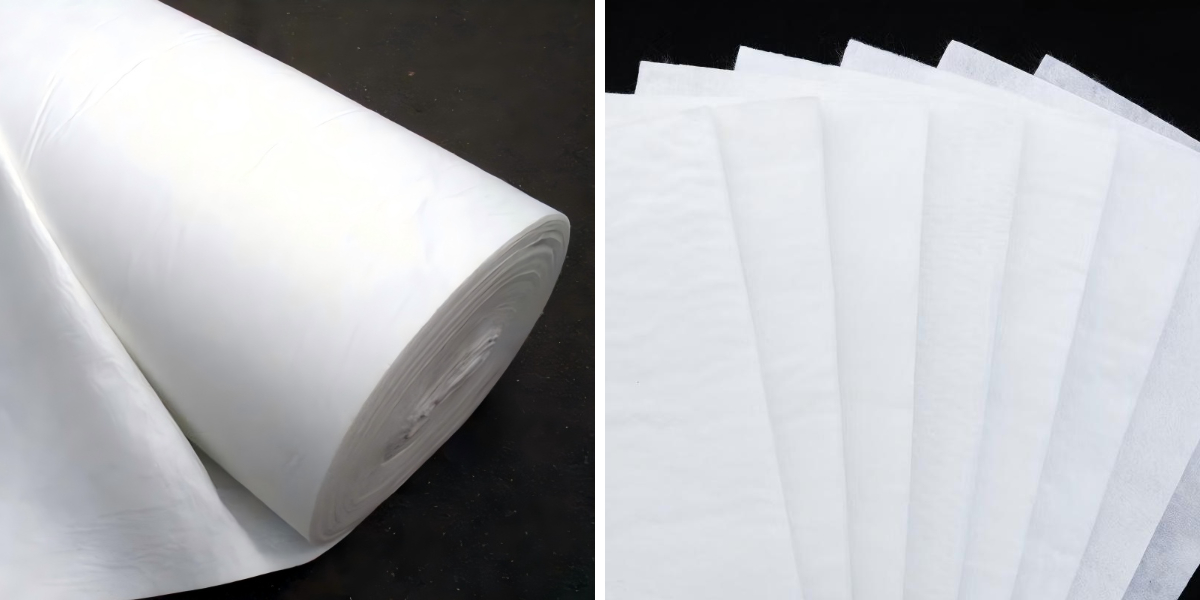

Geotextiles—including geotextile cloth, non woven geotextile, and geotechnical cloth—are foundational to construction, landscaping, and erosion manage projects. Their potential to filter, separate, reinforce, and defend soil makes them indispensable, however even small set up blunders can render these substances ineffective. From mistaken web page prep to mistaken cloth selection, errors regularly lead to luxurious rework, decreased durability, or task failure. This information breaks down the most frequent geotextile set up pitfalls and offers actionable techniques to keep away from them, making sure your assignment leverages the full plausible of these versatile fabrics.

Why Geotextile Installation Precision Matters

Geotextile material and non woven geotextile remember on applicable set up to supply their designed benefits. A misaligned or broken geotextile can fail to stop soil mixing, clog drainage systems, or enable erosion to occur—undermining the entirety from roadbeds to backyard beds. For example, a poorly secured geotechnical material on a slope may additionally shift at some point of heavy rain, main to sediment runoff and slope instability. Even minor errors, like overlapping fabric incorrectly, can create vulnerable factors that compromise the whole system. By fending off these mistakes, you make sure your geotextile set up is durable, compliant, and constructed to stand up to environmental stressors.

Mistake 1: Choosing the Wrong Geotextile Material

One of the most necessary blunders is choosing a geotextile that doesn’t in shape venture requirements. Geotextile cloth, non woven geotextile, and geotechnical material every have special properties—non-woven fabric excel at filtration, whilst woven choices provide finest tensile electricity for reinforcement. Using a light-weight non-woven geotextile for a high-traffic avenue base, or a woven fabric for exceptional soil filtration, will lead to untimely failure.

How to Avoid It

Start through defining undertaking goals: Are you filtering sediment, keeping apart soil layers, or reinforcing a structure? For filtration (e.g., drainage ditches), pick out a non woven geotextile with suitable pore dimension to lure particles whilst permitting water flow. For reinforcement (e.g., avenue subgrades), choose for a long lasting geotechnical fabric with excessive tensile strength. Consult fabric specs and work with suppliers to healthy geotextile weight, permeability, and UV resistance to your site’s stipulations (e.g., chemical exposure, temperature fluctuations). Never compromise on quality—cheaper, ill-suited substances price greater in the lengthy run.

Mistake 2: Inadequate Site Preparation

Geotextiles function satisfactory on clean, smooth, and compacted surfaces. Yet many installers bypass desirable website prep, leaving rocks, roots, or uneven soil under the fabric. Sharp particles can puncture geotextile cloth, whilst uncompacted soil settles over time, developing wrinkles or gaps in the material.

How to Avoid It

Begin by way of clearing the website online of all vegetation, rocks, roots, and development waste. Remove massive particles and grind down stumps to stop future punctures. Grade the floor to make certain uniformity—fill low spots with compactable soil and degree excessive ridges. Compact the soil in layers the use of a vibratory curler or plate compactor to take away air pockets and forestall settlement. For initiatives involving slopes, make sure the gradient is constant and steady earlier than laying non woven geotextile or geotechnical cloth. A closing walkthrough to test for hidden risks (e.g., metallic fragments, sharp stones) is vital to keep away from post-installation damage.

Mistake 3: Improper Fabric Placement and Alignment

Even remarkable geotextile fabric fails if laid incorrectly. Common mistakes encompass stretching the cloth too tight, leaving immoderate slack, or misaligning seams. Overstretching can motive tears below tension, whilst too plenty slack leads to wrinkles that lure water or debris. Misaligned seams create gaps the place soil can migrate or water can seep through.

How to Avoid It

Unroll the geotextile material slowly and enable it to loosen up for 24 hours (if possible) to accommodate thermal expansion. Lay the cloth parallel to the route of water float or visitors to maximize effectiveness. For seams, overlap non woven geotextile by means of 15–30 cm (wider for slopes or high-flow areas) and invulnerable with geotextile tape or staples to forestall separation. Avoid stretching the fabric—leave mild slack to adapt to soil movement. On slopes, anchor the pinnacle and backside edges of geotechnical material with trenches or staples to stop sliding at some stage in backfilling or heavy rain.

Mistake 4: Neglecting Seam and Edge Security

Seams and edges are the weakest factors of any geotextile installation. Failing to impervious them exact approves water, soil, or vegetation to penetrate, undermining the fabric’s function. For example, unsecured edges on a panorama mission can also lift, permitting weeds to develop thru gaps in geotextile cloth.

How to Avoid It

Reinforce seams with double-layer overlaps or adhesive tape, mainly for tasks involving excessive water float (e.g., French drains). On giant installations, use mechanical fasteners (e.g., staples, pins) spaced 30–45 cm aside alongside seams to hold the cloth in place. For facet security, bury the perimeter of non woven geotextile in a 15–20 cm deep trench, backfill with compacted soil, and tamp down to lock it in position. On slopes, add more anchoring at the toe and crest to stop the material from slipping for the duration of heavy rainfall or backfilling.

Mistake 5: Damaging Geotextiles During Backfilling

Backfilling is a high-risk segment for geotextile damage. Dropping heavy substances (e.g., gravel, rocks) without delay onto geotechnical fabric can purpose punctures, whilst dragging tools over the cloth leads to tears. Even small holes can enlarge over time, compromising the complete system.

How to Avoid It

Protect the geotextile throughout backfilling by using laying a skinny layer of sand or first-rate soil over the cloth earlier than including heavier materials. Use shovels or reduced impact tools to vicinity fill—avoid dumping fabric from height. For massive projects, use plywood or brief mats to distribute the weight of equipment over geotextile cloth. Inspect the material often at some stage in backfilling and restore any tears or punctures at once with geotextile patches and adhesive.

Mistake 6: Skipping Post-Installation Inspection

Many installers think about the job finished as soon as backfilling is complete, however skipping a last inspection skill hidden mistakes go unaddressed. Small tears, misaligned seams, or free edges can also now not be apparent at the beginning however can irritate over time, main to expensive repairs.

How to Avoid It

Conduct a thorough post-installation inspection: Walk the complete region to take a look at for tears, wrinkles, or gaps in geotextile cloth. Verify that seams are invulnerable and edges are anchored properly. For drainage projects, take a look at water drift to make certain the non woven geotextile is filtering efficiently besides clogging. Document any troubles with images and restore them immediately—don’t extend fixes, as minor troubles expand quickly. For long-term projects, agenda periodic inspections to reveal the geotextile’s circumstance and tackle put on earlier than it leads to failure.

Conclusion: Mastering Geotextile Installation for Long-Term Success

Avoiding frequent geotextile set up errors is about interest to detail—from choosing the proper geotechnical material to securing seams and inspecting the last product. By matching substances to undertaking needs, getting ready the website online thoroughly, and dealing with the cloth with care, you make certain your geotextile material or non woven geotextile can provide on its promise of sturdiness and performance.

Whether you’re working on a residential landscaping project, a business building site, or an environmental erosion manage initiative, suited set up is the distinction between a undertaking that lasts many years and one that fails inside years. Invest the time to do it right, and you’ll leverage the full advantages of geotextiles—cost savings, decreased maintenance, and a resilient, long-lasting result.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province