Woven vs. Non-Woven Geotextiles: A Simple Guide to Choosing the Right Type

Choosing the proper geotextile for your mission is a foundational decision. While frequently all referred to as "filter fabric" or geo fabric, the two important types—woven and non-woven—are engineered for fantastically one-of-a-kind purposes. Selecting the incorrect one can lead to task failure, luxurious repairs, and frustration. This easy information cuts via the confusion, explaining how every is made, their key strengths, and precisely which initiatives they are designed for, whether or not you are a contractor, engineer, or a DIY fanatic choosing geotextile panorama fabric.

Understanding the Basics: How They Are Made

The manufacturing procedure defines their necessary properties.

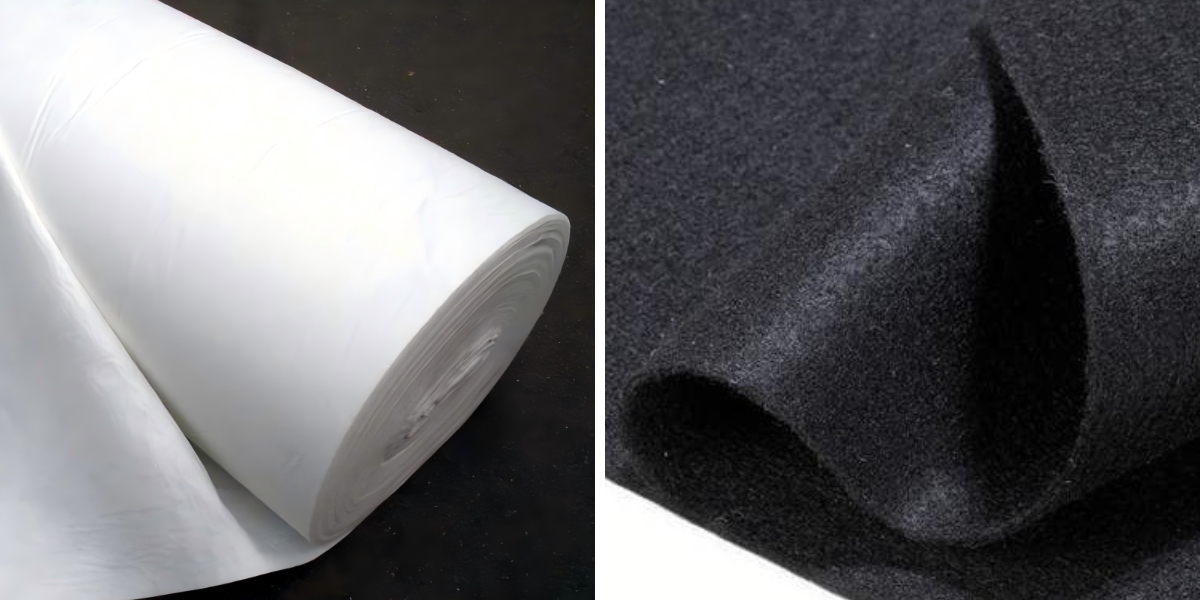

Woven Geotextiles: The High-Strength Fabric

These are produced with the aid of interlacing character polypropylene or polyester yarns on a loom, an awful lot like common textiles. This creates a dimensionally secure sheet with excessive tensile strength. Think of it as a robust, sheet-like grid or mesh. The ensuing geo cloth is strong, has a clean surface, and aspects well-defined, sieve-like openings.

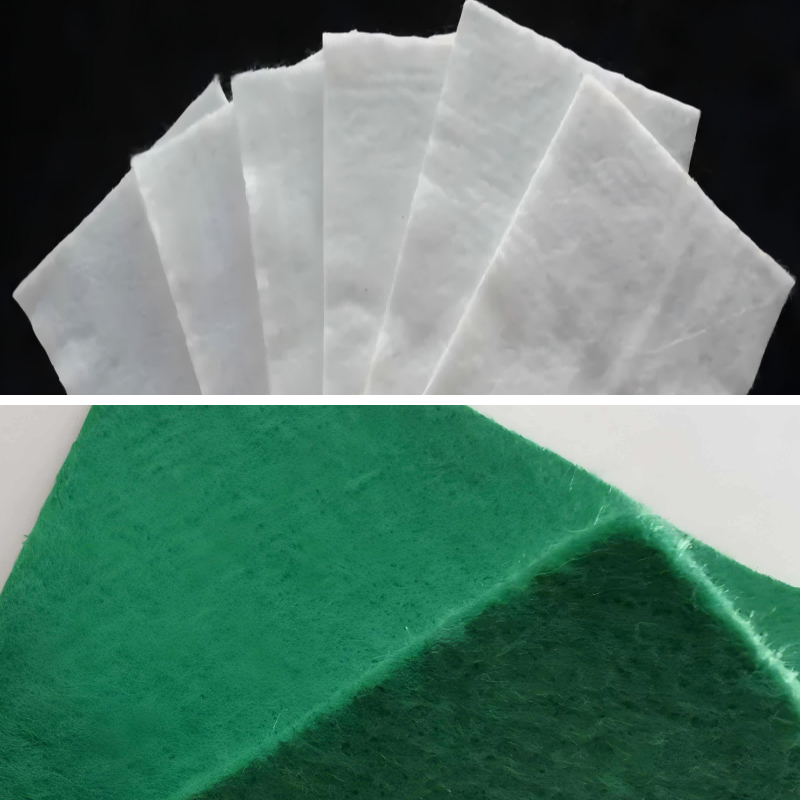

Non-Woven Geotextiles: The Versatile Filter

Non-wovens are made by using taking quick artificial fibers, arranging them in a random web, and then bonding them together—most regularly via needle-punching (mechanically entangling the fibers with barbed needles) or heat-bonding. This creates a thicker, felt-like geotextile with a fuzzy texture. Its shape is a three-d matrix of interconnected pores, making it an gorgeous filter and separator.

Head-to-Head: Key Properties and Strengths

To pick correctly, you should in shape the material's strengths to your project's important need.

Tensile Strength and Load-Bearing

Woven: The clear winner. Their interlaced yarns grant remarkable tensile power (the capacity to face up to pulling forces) with low elongation (minimal stretch). This makes them best for soil reinforcement, stabilization, and developing a steady working platform on gentle ground.

Non-Woven: Have decrease tensile energy and greater elongation. They are now not designed for full-size reinforcement however as a substitute for separation and filtration.

Filtration and Drainage

Non-Woven: The undisputed champion for in-plane water flow. Their thick, porous shape lets in water to go freely via their thickness (permittivity) and additionally inside the airplane of the cloth (transmissivity). This makes them best for drainage functions in the back of keeping partitions or in French drains.

Woven: Provide suitable cross-plane filtration however commonly have a decrease drift rate. Their important function is separation, now not high-volume drainage.

Puncture and Tear Resistance

Non-Woven: Their thick, fibrous mat affords top notch cushioning and multi-directional puncture resistance, making them magnificent for defending subtle geomembranes from sharp rocks.

Woven: Offer top puncture resistance however excel in tear resistance, which means a small nick is much less in all likelihood to propagate into a massive rip beneath tension.

Choosing the Right Type for Your Project

Now, let's practice this know-how to real-world applications, inclusive of frequent makes use of for geotextile panorama fabric.

When to Choose a WOVEN Geotextile:

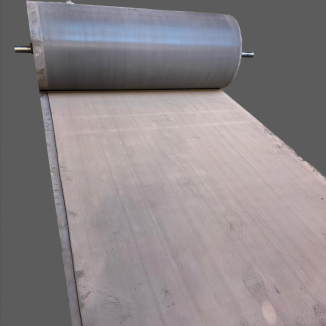

Road and Pavement Base Stabilization: Under roads, parking lots, and driveways to separate the mixture base from the gentle subgrade and supply reinforcement.

Soil Reinforcement for Slopes and Embankments: To support soil and enable for steeper, extra steady slopes.

Under Heavy Loads: Beneath mixture for development get entry to roads or heavy gear pads the place excessive tensile electricity is fundamental to stop rutting.

Railway Track Bed Support: For separation and stabilization underneath ballast.

When to Choose a NON-WOVEN Geotextile:

Drainage and Filtration: As a filter wrap round perforated drainage pipes, in French drains, or in the back of protecting walls.

Separation with Drainage: Between distinctive soil layers in landscaping or beneath paved areas the place each separation and water motion are needed.

Erosion Control: Under rip-rap (rock armor) on slopes or shorelines, the place it acts as a filter to forestall soil loss whilst permitting water to pass.

Protection Layer: Cushioning and defending pond liners (geomembranes) from puncture.

Landscape Fabric for Weed Control: When used as a geotextile panorama cloth in gardens, a non-woven cloth is frequently desired due to the fact it lets in water and air to permeate to plant roots whilst suppressing weeds. It is now not designed for excessive energy however for filtration and separation in planting beds.

Practical Considerations and Common Mistakes

Mistake #1: Using Landscape Fabric Under Gravel Driveways.

A thin, low-cost geotextile panorama cloth offered at backyard facilities will rapidly degrade underneath the weight of gravel and vehicles. For a driveway, you want a heavy-duty woven geo cloth designed for separation and reinforcement.

Mistake #2: Choosing via Weight or Thickness Alone.

A heavier non-woven may additionally be thicker however nonetheless lack the tensile power of a lighter woven fabric. Always choose based totally on the characteristic (separation, reinforcement, filtration, drainage) and the applicable ASTM take a look at values, now not simply bodily specs.

Mistake #3: Installing it Upside Down.

Some non-woven fabric have a easy and a fuzzy side. Generally, the easy facet faces the finer soil or drainage aggregate. Always test the manufacturer's recommendations.

Conclusion: Function Over Form

The preference between woven and non-woven geotextile is no longer about which is "better," however about which is right for the job at hand.

Think "STRENGTH & STABILITY"? Choose a Woven Geotextile.

Think "FILTRATION & DRAINAGE"? Choose a Non-Woven Geotextile.

For landscaping and weed control, a non-woven geotextile panorama material serves its purpose. For structural initiatives like roads, slopes, or underneath heavy loads, a woven geo material is essential. By appreciation this essential distinction, you can confidently specify the proper material, making sure your assignment is constructed on a solid, practical basis that will operate for years to come. Always seek advice from task specs or a geotechnical engineer for necessary applications.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province