How to Choose the Right Geotextile for Your Project (Weight, Material, UV Resistance)

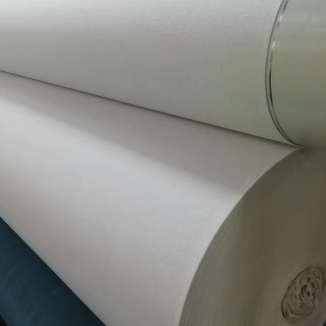

Geotextiles are indispensable elements in existing day construction, civil engineering, and landscaping projects. Whether you’re working on avenue construction, drainage systems, erosion control, or soil stabilization, figuring out on the appropriate geotextile material can make or smash the success of your project. With a wide variety preferences available—from exceptional weights and supplies to a number degrees of UV resistance—it’s essential to apprehend how each thing impacts performance. In this guide, we’ll smash down the key troubles to help you choose the nice geo fabric for your specific needs.

Understanding Geotextile Weight: Why It Matters

The weight of a geotextile is one of the most imperative factors to consider, as it straight away influences its strength, durability, and suitability for one-of-a-kind applications. Geotextile weight is typically measured in ounces per rectangular yard (oz/yd²) or grams per rectangular meter (g/m²), and it tiers from lightweight (as low as three oz/yd²) to heavyweight (up to 30 oz/yd² or more).

Lightweight Geotextiles (3–8 oz/yd²)

Lightweight geotech fabric is ideal for initiatives the area filtration and separation are the essential goals, as a replacement than heavy load-bearing. These merchandise are regularly used in landscaping, outside drainage, or as a barrier between soil and mulch. Their lightweight nature makes them elementary to deal with and install, then again they lack the tensile strength desired for high-traffic or heavy-duty applications. For example, if you’re growing a French drain in a residential yard, a 4–6 oz/yd² geotextile fabric will efficaciously filter water even as stopping soil from clogging the drain pipe.

Medium-Weight Geotextiles (9–15 oz/yd²)

Medium-weight alternatives strike a steadiness between strength and versatility, making them suitable for a considerable differ of projects. They are normally used in avenue constructing as a separation layer between subgrade and aggregate, in erosion manipulate on slopes with lifelike water flow, or as a stabilizer for parking lots. A 12 oz/yd² geo fabric in this category affords ample puncture resistance to face up to heavy equipment while conserving permeability for water drainage.

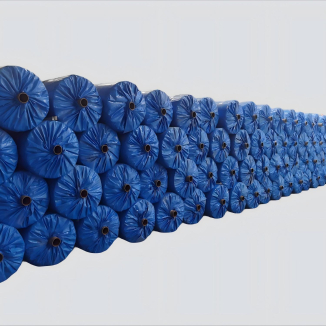

Heavyweight Geotextiles (16+ oz/yd²)

Heavyweight geotech fabric is designed for extreme conditions, such as high-traffic highways, landfill liners, or shoreline protection. These merchandise furnish amazing tensile strength, tear resistance, and durability, making them succesful of withstanding regular stress from heavy thousands or harsh environmental factors. A 20 oz/yd² geotextile, for instance, can act as a reinforcement layer in avenue bases, stopping soil deformation and extending the lifespan of the pavement.

When identifying on weight, continuously refer to mission specs and soil conditions. Sandy soils may additionally additionally require lighter filtration, while clayey or unstable soils normally demand heavier reinforcement.

Decoding Geotextile Materials: Polypropylene vs. Polyester vs. Nylon

The material of your geotextile cloth determines its chemical resistance, temperature tolerance, and frequent average overall performance in specific environments. The three most typical elements are polypropylene, polyester, and nylon, each with unique advantages.

Polypropylene Geotextiles

Polypropylene is the most appreciably used material for geo material due to its affordability and versatility. It offers remarkable resistance to acids, alkalis, and herbal solvents, making it satisfactory for duties involving chemical exposure, such as landfill liners or industrial internet site drainage. Polypropylene is moreover lightweight and accessible to install, alternatively it has reduce tensile electrical energy in distinction to different components and can degrade over time when uncovered to prolonged UV radiation. For this reason, it’s typically dealt with with UV stabilizers for out of doorways use in functions like short erosion manipulate or agricultural drainage.

Polyester Geotextiles

Polyester geotech fabric is considered for its immoderate tensile strength and dimensional stability, even under extreme temperatures. It retains its energy when wet, making it a pinnacle desire for eternal initiatives like riverbank stabilization, coastal protection, or reinforced soil structures. Polyester is moreover superbly resistant to UV degradation, which extends its lifespan in out of doorways settings. While polyester is larger luxurious than polypropylene, its sturdiness makes it a competitively priced choice for long-term duties the area typical overall performance is critical.

Nylon Geotextiles

Nylon geotextiles are valued for their elasticity and abrasion resistance, making them fabulous for dynamic functions the area flexibility is needed, such as in areas with everyday soil movement or vibration. However, nylon is a whole lot much less resistant to chemical compounds and moisture than polypropylene or polyester, and it tends to soak up water, which can restrict its electrical energy over time. As a result, nylon geotextile fabric is a whole lot much less usually used in civil engineering and more regularly observed in specialised functions like short constructing boundaries or lightweight filtration systems.

When determining on a material, mirror onconsideration on the project’s lifespan, publicity to chemical materials or moisture, and temperature fluctuations. For eternal out of doorways projects, polyester is generally the pleasant choice, at the same time as polypropylene works excellent for non permanent or budget-conscious applications.

UV Resistance: Protecting Your Geotextile from Sun Damage

Ultraviolet (UV) radiation from the photo voltaic can cause large degradation in geotextiles over time, weakening their structure and decreasing their effectiveness. This is by and large actual for duties the area the geo fabric is uncovered to direct daylight hours for extended periods, such as avenue shoulders, slope stabilization, or rooftop gardens.

How UV Degradation Affects Geotextiles

UV rays wreck down the molecular bonds in geotextile materials, most important to brittleness, loss of tensile strength, and eventual failure. Polypropylene is in particular inclined to UV damage, at the same time as polyester and nylon provide greater natural resistance. Without acceptable UV protection, even incredible geotech material can deteriorate in as little as 6–12 months in direct sunlight, compromising the total project.

Choosing UV-Resistant Geotextiles

When finding out on a geotextile for outdoor use, show up for merchandise labeled as “UV-stabilized” or “UV-resistant.” These geotextile material preferences are dealt with with aspects that soak up or replicate UV rays, slowing down the degradation process. The stage of UV resistance is often measured by means of way of the material’s functionality to hold electricity after prolonged exposure—look for merchandise that maintain at least 50% of their actual tensile strength after 500–1000 hours of accelerated UV testing.

Installation Tips to Minimize UV Exposure

Even with UV-stabilized geo fabric, minimizing photo voltaic publicity can prolong its lifespan. Cover the geotextile with soil, aggregate, or vegetation as rapidly as possible after installation. For initiatives the vicinity publicity is unavoidable (e.g., short erosion control), select a heavyweight, UV-resistant material designed for non everlasting use. Regular inspections can moreover aid find out early signs and symptoms of UV damage, enabling for nicely timed repairs or replacements.

Final Tips for Choosing the Right Geotextile

Selecting the high-quality geotextile material requires balancing weight, material, and UV resistance with your project’s unique needs. Here’s a speedy suggestions to data your decision:

Assess the project’s purpose: Is it for filtration, separation, reinforcement, or erosion control?

Evaluate environmental conditions: Consider soil type, moisture levels, chemical exposure, and UV exposure.

Check specifications: Ensure the geotextile meets company necessities for strength, permeability, and durability.

Consult experts: If unsure, obtain out to engineers or suppliers with ride in related projects.

By taking these factors into account, you’ll be in a role to pick out a geo fabric or geotech cloth that now now not completely meets your project’s requirements then again moreover stands the test of time. Remember, investing in the ideal geotextile upfront can store you time, money, and issues in the prolonged run.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province