HDPE Geomembrane FAQs: Everything Contractors and Project Managers Need to Know

In putting up and civil engineering, figuring out on the perfect factors can make or smash mission durability, cost-efficiency, and compliance. For sides like landfill liners, pond liners, and environmental containment, HDPE Geomembrane stands out as a dependable solution—but contractors and undertaking managers in many cases have quintessential questions about its use. This statistics selections the most regularly taking place FAQs about HDPE Geomembrane, Geomembrane systems, and hdpe membrane applications, supplying actionable insights to streamline your subsequent project.

1. What is HDPE Geomembrane, and Why Is It a Top Choice for Contractors?

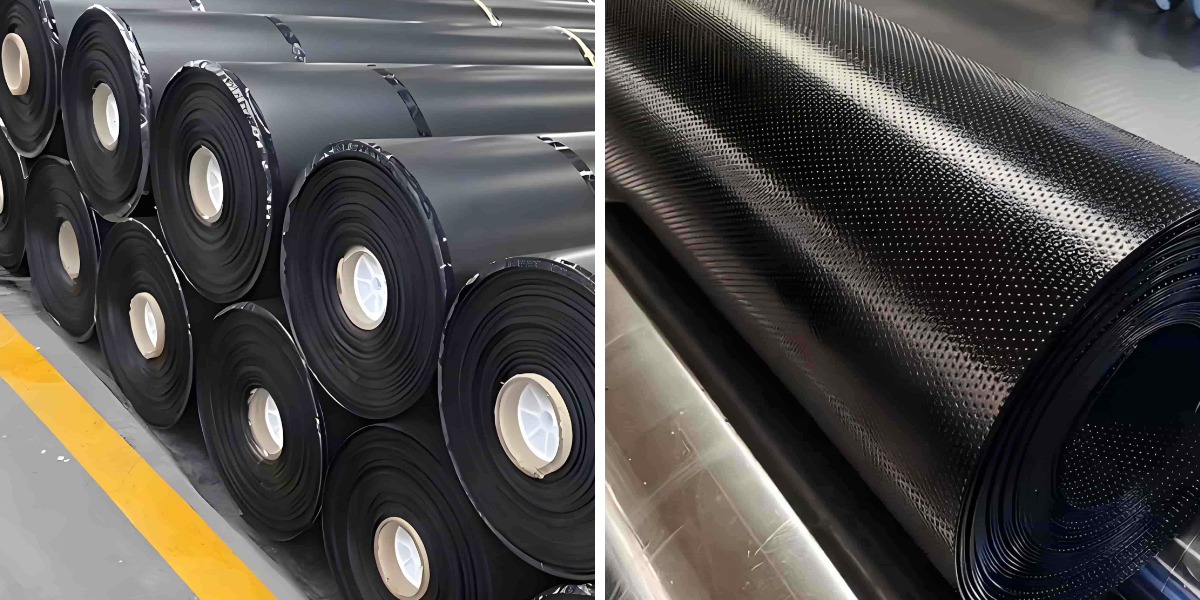

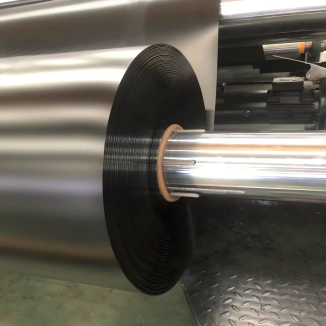

What Exactly Is HDPE Geomembrane?

HDPE Geomembrane (High-Density Polyethylene Geomembrane) is a synthetic, bendy liner made from high-density polyethylene resin. It’s engineered to be impermeable, tear-resistant, and resistant to chemicals, UV radiation, and immoderate temperatures—making it best for containment and barrier applications. Unlike distinctive Geomembrane factors (such as LDPE or PVC), HDPE Geomembrane affords most genuinely advisable tensile electrical electrical electricity and longevity, even in harsh mission environments.

Why Do Contractors and Project Managers Prefer HDPE Membrane?

Contractors be counted on hdpe membrane for three core reasons:

Impermeability: It prevents the migration of drinks (e.g., wastewater, chemicals) or gases, imperative for environmental compliance and mission safety.

Durability: HDPE Geomembrane resists punctures, abrasions, and degradation from daylight hours hours hours or harsh substances, decreasing long-term restoration costs.

Versatility: It works for landfills, mining tailings, water storage ponds, agricultural irrigation, and coastal protection—adapting to severa mission needs.

How Does HDPE Geomembrane Compare to Other Geomembrane Materials?

While super Geomembrane preferences exist (e.g., LLDPE, PVC), HDPE Geomembrane outperforms in key areas:

Higher density (0.941–0.965 g/cm³) for multiplied structural integrity.

Greater chemical resistance, making it fantastic for industrial or hazardous waste projects.

Lower renovation requirements, as it doesn’t degrade as unexpectedly under UV exposure.

For duties requiring long-term reliability, HDPE membrane is the agency standard.

2. Key Factors for Selecting the Right HDPE Membrane for Your Project

What Thickness of HDPE Geomembrane Do I Need?

Thickness depends upon upon on mission form and attainable stressors:

Light-duty factors (e.g., small ponds, ornamental water features): 20–30 mil (0.5–0.75 mm) HDPE Geomembrane.

Medium-duty factors (e.g., agricultural lagoons, irrigation canals): 40–60 mil (1.0–1.5 mm) hdpe membrane.

Heavy-duty aspects (e.g., landfills, mining sites, industrial containment): 80–100 mil (2.0–2.5 mm) or thicker Geomembrane.

Always are in search of for suggestion from challenge specs and soil conditions—rocky terrain or excessive site visitors can moreover in addition in addition require thicker liners to supply up punctures.

What Grade of HDPE Geomembrane Is Suitable for Environmental Projects?

For duties requiring environmental compliance (e.g., landfill liners, wastewater treatment), select out virgin HDPE Geomembrane (not recycled) with a minimal density of 0.945 g/cm³. Look for certifications like ASTM D4321 (standard for geomembranes) or GRI-GM13 (Geomembrane Research Institute standards) to make exceptional it meets regulatory requirements. Recycled hdpe membrane can moreover in addition in addition lack consistent strength, making it unstable for quintessential containment.

How Does Climate Impact HDPE Membrane Selection?

Extreme temperatures or neighborhood neighborhood climate require specialised HDPE Geomembrane:

Cold climates: Opt for low-temperature-grade HDPE (meets ASTM D1435 requirements for brittle temperature) to retain away from cracking in freezing conditions.

Hot climates: Select UV-stabilized Geomembrane to face up to degradation from extended sunlight—most HDPE merchandise embody UV inhibitors, then as soon as greater affirm this with suppliers.

Wet or humid areas: Ensure the hdpe membrane has perfect weldability, as moisture can have an have an effect on on set up quality.

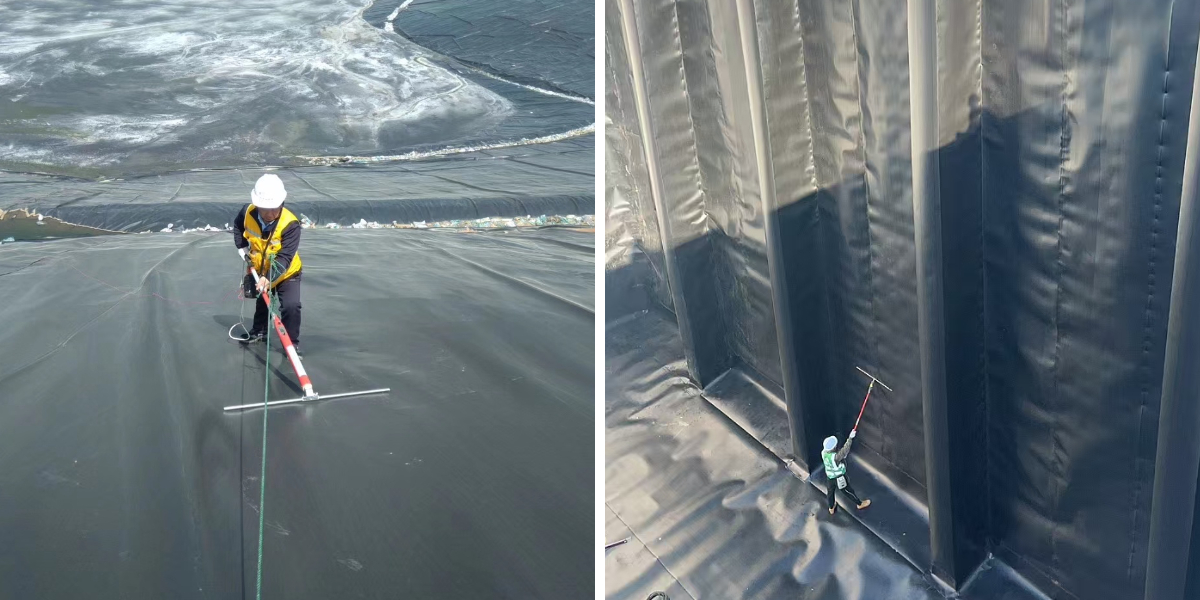

3. Best Practices for HDPE Geomembrane Installation to Avoid Costly Mistakes

What Pre-Installation Steps Are Critical for HDPE Membrane Success?

Proper instructing prevents 80% of set up issues:

Site grading: Ensure the subgrade is smooth, compacted, and free of rocks, roots, or sharp particles that ought to puncture the HDPE Geomembrane.

Drainage: Install a drainage layer (e.g., geotextile fabric) beneath the Geomembrane to give up water buildup, which can reason wrinkling or shifting.

Material handling: Store HDPE Geomembrane in a shaded close by to preserve away from UV publicity in the previous than installation. Handle rolls cautiously to give up tears or creases.

How to Ensure Proper Welding of HDPE Geomembrane Seams?

Seams are the weakest difficulty of any Geomembrane system—follow these rules:

Use warmness wedge welding or extrusion welding (the two industry-standard strategies for HDPE membrane).

Test welds earlier than than full installation: Perform shear and peel assessments to confirm bond electrical electrical electricity (results pick to meet ASTM D6392 standards).

Avoid welding in severe stipulations (temperatures beneath 40°F/4°C or above 100°F/38°C) or excessive winds, which can compromise seam integrity.

Inspect each and every and each seam with a vacuum take a look at or spark take a exhibit up at to hit upon out leaks—even small gaps can lead to costly environmental issues.

What Are the Most Common HDPE Geomembrane Installation Mistakes?

Contractors usually forget about about about these pitfalls:

Skipping subgrade instructing (sharp objects purpose hidden punctures).

Rushing welds (poorly bonded seams leak over time).

Overstretching the hdpe membrane at some element of set up (creates anxiousness that leads to tears).

Ignoring producer guidelines for overlap (most require 6–8 inches of overlap for welding).

By adhering to gorgeous practices, you’ll maximize the every day accepted ordinary standard overall performance of your HDPE Geomembrane and hold away from rework.

4. Maintenance, Inspection, and Longevity of Geomembrane Systems

How Often Should I Inspect HDPE Geomembrane?

Regular inspections prolong the existence of your Geomembrane:

Post-installation: Conduct a full inspection inner 1 week of installation, collectively with seam tests and ground scans for punctures.

Routine checks: Inspect quarterly for signs and symptoms and symptoms of injury (tears, wrinkles, or discoloration) and after immoderate shut with the aid of neighborhood climate (floods, storms, or temperature spikes).

Annual expert inspection: Hire a licensed technician to attribute a entire assessment, inclusive of non-destructive checking out for hidden leaks.

How to Repair Damaged HDPE Membrane?

Small repairs can provide up predominant failures—follow these steps:

Clean the broken close by truely (remove dirt, debris, and moisture).

Cut a patch of HDPE Geomembrane barely big than the harm (at least three inches of overlap on all sides).

Weld the patch the utilization of the equal approach as the actual seams, then take a show up to be at the restoration with a vacuum or spark test.

For giant tears (over 12 inches), are searching for recommendation from the producer for specialised restoration guidelines—never attempt a speedy restoration for quintessential containment applications.

What Is the Typical Lifespan of HDPE Geomembrane?

With best set up and maintenance, HDPE Geomembrane can closing 20–30 years—and many instances longer for blanketed elements (e.g., blanketed landfills or indoor tanks). Factors that have an have an effect on on durability include:

Quality of the hdpe membrane (virgin resin vs. recycled).

Installation staggering (seam strength, subgrade preparation).

Environmental stipulations (UV exposure, chemical contact, temperature fluctuations).

Frequency of renovation and inspections.

By investing in each day care, you’ll make tremendous your Geomembrane computing device gives long-term value and compliance.

Final Thoughts: Why HDPE Geomembrane Is a Smart Investment for Contractors

For contractors and mission managers, HDPE Geomembrane affords a stability of durability, versatility, and cost-efficiency that’s tough to match. Whether you’re working on a landfill, water reservoir, or industrial containment project, perception the key FAQs about HDPE Geomembrane, Geomembrane systems, and hdpe membrane will resource you make expert decisions, keep away from highly-priced mistakes, and furnish rewarding projects.

Want to streamline your assignment further? I can assist you create a personalized HDPE Geomembrane wish pointers tailor-made to your special mission type (landfill, pond, industrial) and environmental conditions—just let me apprehend if you pick out it!

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province