Using Woven Geotextile for Road Stabilization and Base Reinforcement

Road and railway infrastructure is the backbone of transportation networks, alternatively it faces normal threats from web page traffic loads, environmental erosion, and soil instability. Traditional avenue base reinforcement methods—such as over-excavation, such as aggregate, or the use of concrete—are typically costly, time-consuming, and unsustainable for long-term performance. Woven geotextile has emerged as a game-changing solution, imparting durability, cost-efficiency, and versatility for stabilizing avenue bases, reinforcing substrates, and mitigating erosion. In this guide, we’ll find out how woven geotextile transforms infrastructure projects, with a middle of attention on its specialised features in avenue construction, railway engineering, and erosion control. We’ll additionally highlight key first-class practices to maximize results, integrating imperative choices like Road Construction Woven Geotextile, Railway Geotextile, and Erosion Control Woven Geotextile.

1. Understanding Woven Geotextile: Core Benefits and Working Principles

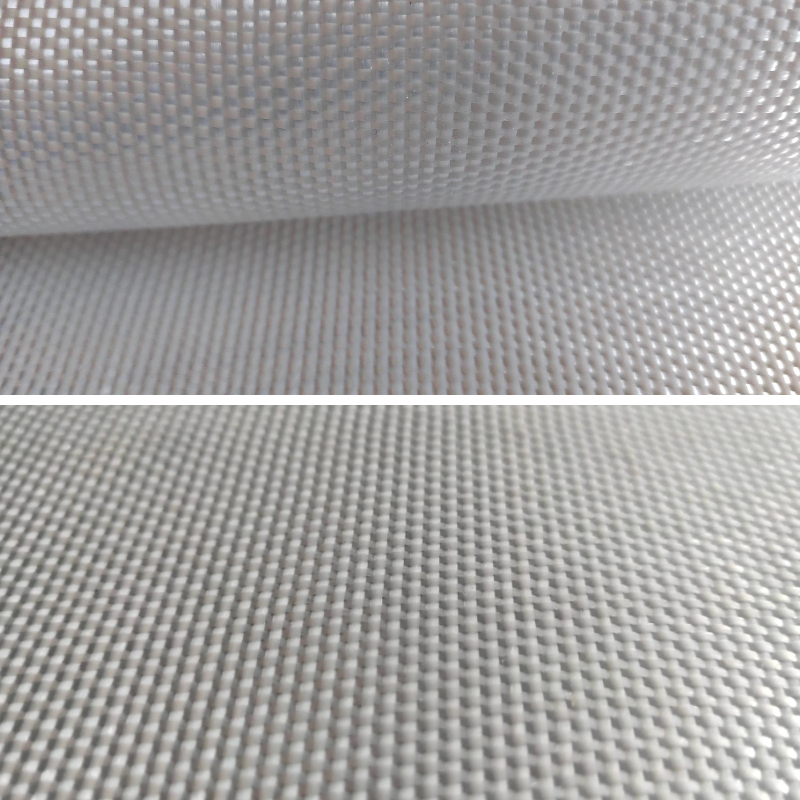

Before diving into applications, it’s essential to preserve shut why woven geotextile is gold standard for stabilization and reinforcement. Unlike non-woven geotextiles, which are bonded fibers, woven geotextile is constructed by way of interlacing high-strength synthetic fibers (typically polyester or polypropylene) in a grid pattern. This form can supply four key aspects that make it quintessential for infrastructure projects: separation, reinforcement, filtration, and drainage.

Key Advantages of Woven Geotextile

High Tensile Strength: The woven grid resists stretching and tearing, even below heavy web site traffic heaps or soil movement. This strength is why Road Construction Woven Geotextile is relied on to red meat up avenue bases—preventing rutting, settlement, and structural failure.

Durability: Synthetic fibers are resistant to UV radiation, chemicals, and natural degradation, making positive a prolonged provider life (often 20+ years) with minimal maintenance.

Filtration & Drainage: The porous grid allows water to ignore through at the same time as trapping soil particles, stopping clogging of the avenue base and decreasing water-related harm like frost heave or erosion.

Cost-Efficiency: By reducing the prefer for excessive aggregate or excavation, woven geotextile cuts cloth and labor costs. For example, Road Construction Woven Geotextile can reduce combination utilization by means of way of up to 30% at the same time as bettering base stability.

At its core, woven geotextile acts as a “separator” between soil layers and constructing materials, stopping mixing that weakens the base. It moreover reinforces the substrate via the usage of distributing heaps evenly, lowering stress on the underlying soil. This twin movement is what makes it a cornerstone of contemporary infrastructure projects—from close by roads to high-speed railways.

2. Road Construction Woven Geotextile: Stabilizing Bases for Heavy Traffic

Roads endure steady stress from vehicles, weather, and soil movement. A susceptible base leads to premature cracking, potholes, and highly-priced repairs. Road Construction Woven Geotextile is engineered to handle these challenges, growing a robust, long-lasting groundwork for every paved and unpaved roads.

How Road Construction Woven Geotextile Enhances Road Performance

Prevents Soil-Aggregate Mixing: When laid between the subgrade (native soil) and the mixture base, Road Construction Woven Geotextile blocks gorgeous soil particles from migrating into the aggregate. This preserves the aggregate’s porosity and load-bearing capacity, maintaining off base degradation over time.

Reduces Settlement: By distributing website online traffic hundreds at some point of a wider area, the geotextile minimizes pressure on the subgrade. This is fundamental for roads developed on mild or unstable soil, the location contract is a imperative risk. For example, in rural areas with prone subgrades, Road Construction Woven Geotextile can restrict contract thru 40-60%, extending the road’s lifespan from 5 years to 15+ years.

Improves Drainage: The woven structure lets in water to drain away from the base, stopping moisture buildup that weakens soil and motives frost damage. This is mainly treasured in areas with heavy rainfall or freeze-thaw cycles.

Application Tips for Road Projects

For most reliable results, set up Road Construction Woven Geotextile on a compacted, convenient subgrade—free of sharp particles that must puncture the fabric. Lay the geotextile with a 15-20cm overlap at seams to make positive continuous coverage, and tightly closed edges with stakes or anchor pins. Cover besides lengthen with aggregate (typically 10-15cm layer) to guard the geotextile from UV damage and site visitors all thru construction. Whether setting up a residential street, highway, or industrial get admission to road, Road Construction Woven Geotextile offers you consistent, reliable base reinforcement.

3. Railway Geotextile: Reinforcing Subgrades for Heavy Loads and Vibration

Railway infrastructure faces distinctive challenges: severe heaps from trains (often 100+ plenty per axle), constant vibration, and the prefer for precise alignment. Even minor contract or subgrade movement can disrupt rail operations, principal to delays or safety hazards. Railway Geotextile is specifically designed to meet these demands, imparting extra nice electricity and steadiness for rail subgrades and ballast layers.

Why Railway Geotextile Stands Out for Rail Projects

Vibration Damping: Trains generate continuous vibration that weakens subgrades over time. Railway Geotextile’s immoderate tensile power absorbs and distributes these vibrations, reducing stress on the underlying soil and stopping differential settlement.

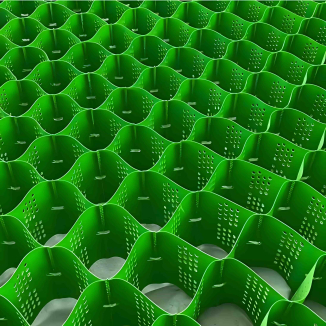

Ballast Stabilization: The geotextile acts as a separator between the ballast (crushed stone) and subgrade, stopping ballast from sinking into soft soil. This preserves the ballast’s potential to information educate hundreds and retain tune alignment.

Erosion Resistance: Railway corridors in many instances span prolonged distances, exposing subgrades to wind, water, and runoff. Railway Geotextile presents a defending layer that prevents soil erosion, in specific in embankments or cuttings.

Critical Considerations for Railway Installations

Railway Geotextile requires higher tensile electrical energy (typically 200-400 kN/m) than stylish avenue geotextiles to face up to train loads. It have to moreover be UV-stabilized and resistant to chemical elements from railway lubricants or de-icing agents. During installation, make certain the geotextile is laid taut to preserve away from wrinkling, which can create inclined points. For high-speed rail projects, pair Railway Geotextile with more reinforcement layers (like geogrids) for most stability. The stop end result is a tune machine that requires lots much less maintenance, minimizes downtime, and ensures safe, smooth operations.

4. Erosion Control Woven Geotextile: Protecting Infrastructure from Environmental Damage

Erosion is a silent hazard to avenue and railway infrastructure. Water runoff, wind, and slope instability can wash away subgrades, undermine embankments, and damage base layers—leading to expensive repairs and safety risks. Erosion Control Woven Geotextile combines stabilization with erosion protection, making it an quintessential issue of infrastructure duties in inclined areas.

How Erosion Control Woven Geotextile Safeguards Infrastructure

Slope Stabilization: Roads and railways normally require embankments or cuts, which are inclined to erosion. Erosion Control Woven Geotextile is laid on slopes to hold soil in region while allowing water to drain. Its woven structure resists the stress of runoff, stopping rilling and gullying.

Base Layer Protection: Even well-compacted avenue bases can erode if uncovered to water. Erosion Control Woven Geotextile acts as a barrier, protecting the base from rainfall and runoff even as maintaining drainage. This is in specific integral at some factor of construction, when the base is shortly exposed.

Complementary to Vegetation: For long-term erosion control, Erosion Control Woven Geotextile can be paired with vegetation (e.g., grass seeds or shrubs). The geotextile retains soil moisture and protects younger plants, while roots in addition support the slope—creating a sustainable, natural safety system.

Best Practices for Erosion Control Applications

When the utilization of Erosion Control Woven Geotextile on slopes, choose out a cloth with amazing weight (typically 200-300 g/m²) for the slope mind-set and soil type. Lay the geotextile parallel to the slope, with overlaps of 20-30cm to make sure full coverage. Secure the pinnacle and bottom edges with anchors to give up uplift from wind or water. For avenue and railway duties shut to water our our bodies (e.g., rivers or lakes), Erosion Control Woven Geotextile can be used in conjunction with riprap or gabions for delivered protection in opposition to wave action.

5. Installation Best Practices for Maximum Performance

Even the highest-quality woven geotextile will underperform if hooked up incorrectly. Follow these key steps to make sure your stabilization and reinforcement project can supply long-lasting results, regardless of whether or not or no longer you’re the use of Road Construction Woven Geotextile, Railway Geotextile, or Erosion Control Woven Geotextile.

Step 1: Prepare the Subgrade

The subgrade have to be compacted, smooth, and free of particles (rocks, branches, sharp objects) that ought to puncture the geotextile. Remove vegetation and topsoil, then compact the soil to gain a density of 95% or higher. For mild subgrades, mirror onconsideration on preloading or inclusive of a skinny layer of mixture before than laying the geotextile.

Step 2: Select the Right Geotextile

Match the geotextile to the project’s needs:

Road projects: Choose Road Construction Woven Geotextile with tensile electrical energy of 100-300 kN/m, relying on traffic volume.

Railway projects: Opt for Railway Geotextile with increased tensile electricity (200-400 kN/m) and vibration resistance.

Erosion control: Select Erosion Control Woven Geotextile with UV stabilization and immoderate permeability for slopes or moist areas.

Step 3: Lay and Secure the Geotextile

Unroll the geotextile cautiously to maintain away from tearing or stretching.

Align seams with a 15-30cm overlap (wider for slopes or high-water areas) and impenetrable with stitches, hog rings, or adhesive tape.

Tension the geotextile to put off wrinkles—wrinkles can create prone elements below load.

Secure edges with stakes, anchor pins, or trench burial to stop movement during mixture placement.

Step 4: Cover with Aggregate or Topsoil

Immediately cowl the geotextile with the specific aggregate (for roads/railways) or topsoil (for erosion control) to protect it from UV damage and constructing traffic. The cowl layer ought to be at least 10cm thick for roads and 15cm for railways.

6. Common Myths and FAQs About Woven Geotextile

Myth 1: Woven geotextile is too luxurious in distinction to everyday methods.

Fact: While upfront fees may also additionally be barely higher, woven geotextile reduces long-term charges through reducing combination usage, minimizing maintenance, and extending infrastructure lifespan. For example, Road Construction Woven Geotextile can preserve 20-30% on aggregate charges and limit fix frequency with the resource of 50%.

Myth 2: Non-woven geotextile works really as properly for stabilization.

Fact: Non-woven geotextiles excel at filtration on the other hand lack the tensile electrical energy of woven varieties. For reinforcement and stabilization, Road Construction Woven Geotextile and Railway Geotextile are superior—they face up to stretching and distribute hundreds higher effectively.

FAQ 1: How prolonged does woven geotextile last?

Answer: With UV stabilization and perfect installation, woven geotextile can last 20-30 years. Railway Geotextile and Road Construction Woven Geotextile are engineered for long-term performance, even beneath heavy loads and harsh conditions.

FAQ 2: Can woven geotextile be used in cold climates?

Answer: Yes—synthetic woven geotextiles are resistant to freeze-thaw cycles. Erosion Control Woven Geotextile is specifically treasured in cold regions, as it prevents frost heave by using capacity of improving drainage.

Conclusion: Woven Geotextile—The Future of Stable, Durable Infrastructure

Woven geotextile has revolutionized avenue and railway construction, providing a sustainable, low in fee preference to everyday reinforcement methods. Whether you’re stabilizing a avenue base with Road Construction Woven Geotextile, reinforcing a railway subgrade with Railway Geotextile, or defending slopes with Erosion Control Woven Geotextile, this versatile fabric can supply unmatched strength, durability, and performance.

By following exquisite practices for fabric selection, installation, and maintenance, you can maximize the lifespan of your infrastructure, restriction costs, and limit environmental impact. As transportation networks face developing demands, woven geotextile will continue to be a crucial machine for developing resilient, reliable roads and railways that stand the take a look at of time.

For engineers, contractors, and undertaking managers, investing in woven geotextile isn’t truly a choice—it’s a dedication to quality, efficiency, and long-term success. Whether you’re working on a small nearby road or a large-scale railway project, the desirable woven geotextile reply will radically exchange your infrastructure from fragile to fortified.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province