The Anatomy of a Composite Geotextile: Geonet, Geotextile, and Membrane Layers

In the world of civil and environmental engineering, effectivity and overall performance are paramount. This is the place the composite geotextile shines. More than simply a easy fabric, it is a high-performance engineered system, meticulously layered to clear up complicated challenges. But what exactly goes into its structure? This article deconstructs the anatomy of a standard composite geotextile, exploring the essential roles of its geonet, geotextile, and membrane layers.

The Core Concept: What is a Composite Geotextile?

A composite geotextile is now not a single cloth however a laminated product that combines two or greater distinctive geosynthetics. By bonding these layers, engineers create a single, multifunctional cloth that performs duties a single layer should in no way gain alone. The fundamental reason is to combine features like drainage, filtration, and containment seamlessly. The most effective combination, frequently referred to as a geotextile impermeable membrane system, brings collectively separation, filtration, in-plane drainage, and a fluid barrier. Understanding this shape is key to specifying the proper product for initiatives like landfill liners, tunnel drainage, or pond lining.

Layer 1: The Geotextile Filter – The First Line of Defense

Every exceptional gadget begins with a robust foundation, and in a composite geotextile, this function is crammed via one or greater layers of non-woven geotextile.

●Function: Filtration and Separation. This layer is positioned without delay in opposition to the soil. Its foremost job is to permit water to pass by via whilst stopping satisfactory soil particles from migrating. This process, acknowledged as filtration, protects the integrity of the different layers from being clogged with silt and clay. Simultaneously, it separates distinct soil layers, stopping them from mixing and dropping their engineered properties.

●Material & Properties: Typically, a needle-punched non-woven polypropylene geotextile is used. This cloth has a random fiber shape that creates hundreds of thousands of tiny pores. It is robust, resistant to organic and chemical degradation, and has awesome permeability. When you see a composite geotextile used in drainage applications, this outer layer is the unsung hero making sure the machine does not fail due to clogging.

Layer 2: The Geonet Drainage Core – The Conduit for Fluids

Sandwiched between the geotextile layers lies the geonet, the workhorse of the drainage function. This thing is what elevates a fashionable geosynthetic into a high-flow composite geotextile.

●Function: In-Plane Drainage and Transmissivity. Unlike a geotextile that drains via its thickness, a geonet is designed to transport fluids inside its airplane over lengthy distances. It acts as a conduit, successfully amassing and channeling water, gases, or leachate to detailed series points. This core layer creates a continuous, high-volume drainage path, relieving hydraulic stress that should in any other case harm structures.

●Material & Properties: Geonets are generally made from polyethylene and are fashioned into a grid-like, open community shape with parallel units of ribs. This creates a collection of channels that provide excessive transmissivity (the in-plane drift capacity) even below full-size compressive loads. In a geotextile impermeable membrane system, the geonet is essential for managing any fluid that may accumulate on the barrier side.

Layer 3: The Impermeable Membrane – The Ultimate Barrier

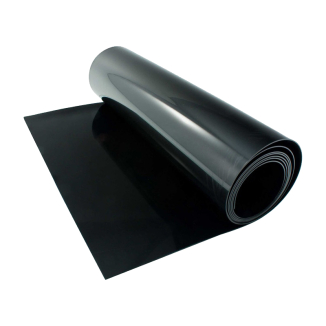

The 1/3 indispensable layer is what transforms the composite into a containment solution. This is the impermeable geotextile component, regularly a geomembrane.

●Function: Containment and Fluid Barrier. This non-stop layer is absolutely impenetrable to drinks and gases. Its sole cause is to create a fantastic barrier, stopping the passage of contaminants, water, or vapors. This is fundamental for environmental protection, stopping pollution from leaching into groundwater or, conversely, stopping groundwater from infiltrating a structure.

●Material & Properties: Common substances consist of HDPE (High-Density Polyethylene), LLDPE (Linear Low-Density Polyethylene), or PVC. These substances are chosen for their very low permeability, excessive chemical resistance, and durability. When this layer is integrated, the product absolutely features as a geotextile impermeable membrane, imparting a whole "all-in-one" answer for lining and capping applications.

The Synergistic Effect: Why Lamination Creates a Superior Solution

The genuine energy of a composite geotextile is not simply in the person layers, however in how they work together. Laminating these aspects creates a synergy that supplies unmatched benefits:

Installation Efficiency: Instead of sourcing, transporting, and putting in three separate materials, contractors cope with a single roll. This extensively reduces labor time, set up errors, and usual undertaking costs.

Guaranteed Performance: The factory-controlled lamination ensures best contact and alignment between the layers. There's no chance of the geonet or geomembrane being broken all through the placement of a separate geotextile, making sure the designed overall performance of the geotextile impermeable membrane is achieved.

Optimized Functionality: Each layer is specially chosen to complement the others. The geotextile protects the geonet and geomembrane; the geonet gives drainage for the geomembrane; and the geomembrane provides the containment. This creates a robust, long-lasting system.

Key Applications of Composite Geotextile Systems

The special anatomy of these composites makes them best for stressful applications:

Landfill Liners and Caps: This is the traditional use for a geotextile impermeable membrane system. It affords the leak-proof barrier (membrane), drainage for leachate and gasoline (geonet), and filtration from the waste and soil cowl (geotextile).

Tunnel and Underground Drainage: The composite geotextile is used at the back of segmental linings to drain water ingress into series pipes whilst stopping soil erosion into the drainage core.

Pond and Reservoir Liners: In functions the place drainage of seepage is wished at the back of the liner, the composite gadget is best for managing water stress and imparting containment.

Green Roof and Plaza Deck Drainage: These structures use a lighter-weight composite geotextile to supply drainage, root protection, and a water retention layer all in one.

Conclusion

Understanding the layered anatomy of a composite geotextile—from the filtering geotextile, thru the draining geonet, to the barrier membrane—reveals why it is such a progressive product in geotechnical engineering. It is a testomony to the electricity of wise design, the place the aggregate of specialised substances creates a answer a ways higher than the sum of its parts. Whether your challenge calls for an impermeable geotextile barrier or a high-performance drainage core, specifying a correct engineered composite geotextile ensures durability, efficiency, and long-term undertaking success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province