Geo Textil

1. Easy construction and high efficiency: fast laying speed, no need for large machinery, greatly shortening the construction period.

2. Good comprehensive performance: A material often has multiple functions such as isolation, reinforcement, drainage, and filtration simultaneously.

3. Cost savings: The material itself, transportation, and construction costs are usually lower than traditional materials such as sand and gravel, resulting in significant economic benefits.

4. Space saving: Thin layer materials take up very little structural space.

5. Environmental Protection: It reduces the damage to the natural environment caused by sand and gravel mining, and can effectively prevent the spread of pollutants and protect the environment in some projects.

Product Introduction:

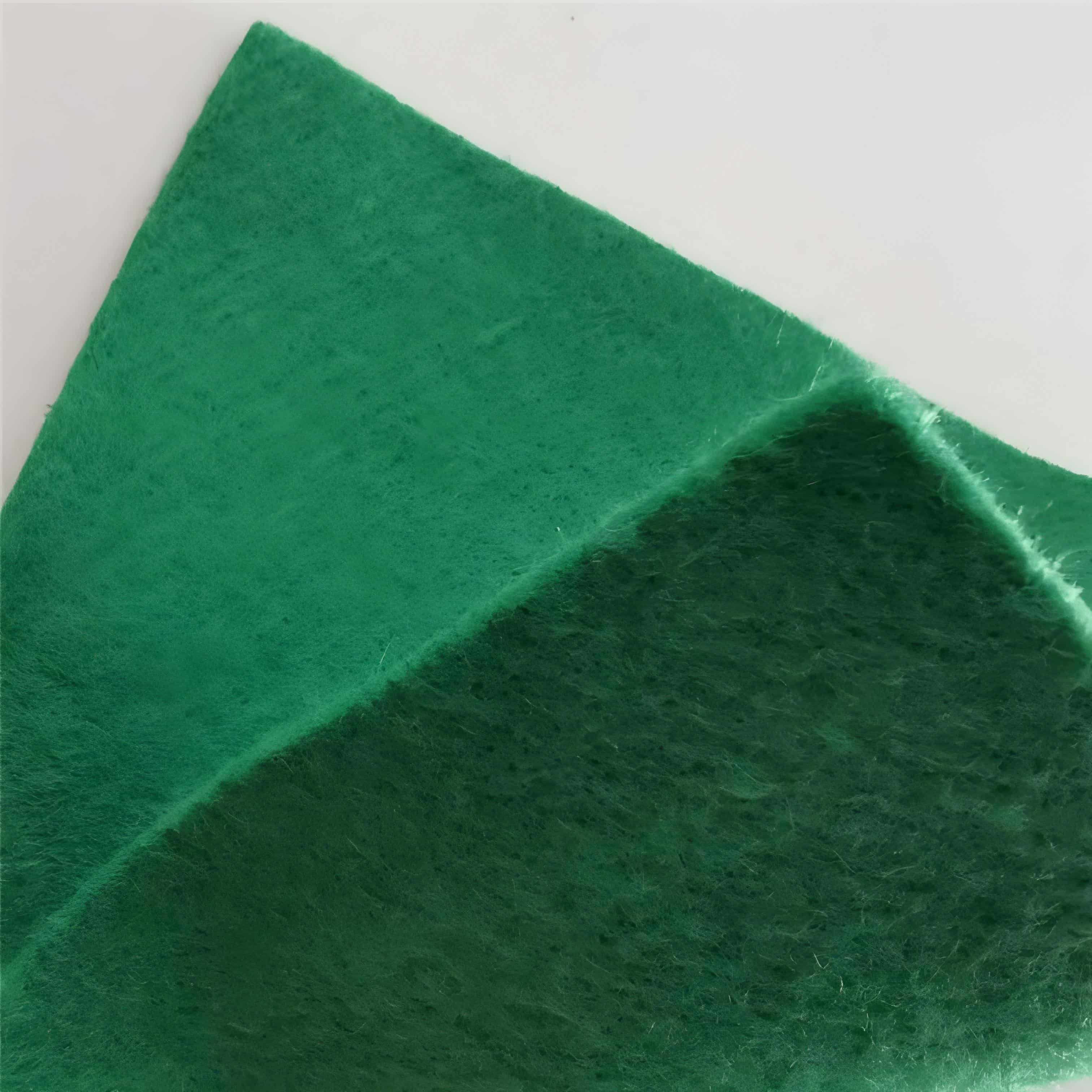

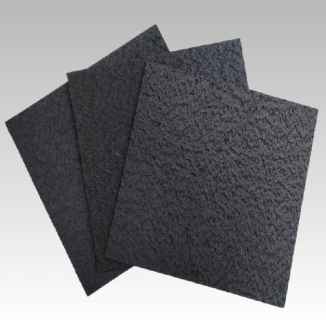

Geo Textil is a synthetic fiber textile or non-woven material specifically used in civil engineering. It is essentially a permeable polymer (usually polypropylene or polyester) sheet or fabric that is placed in or between soil, rock, or other geotechnical materials to serve engineering purposes such as reinforcement, protection, drainage, filtration, and isolation.

Simply put, it is a type of "cloth" buried in the soil, but its function is far beyond ordinary cloth, and it is an indispensable new engineering material in modern civil engineering.

Feature

The reason why geotextiles can be widely used is due to their following core characteristics:

1. High strength: It has good tensile, tear, burst and puncture strength, and can withstand the destructive force during construction and the load during long-term use.

2. Durability: Made of synthetic fibers, it is resistant to chemical corrosion, microorganisms, and insect infestations, and can maintain long-term stability in different acidic and alkaline soils and water.

3. Permeability: It has a porous structure that allows water to pass smoothly through its surface, while effectively preventing excessive loss of soil particles.

4. Flexibility: With a soft texture, it can adapt to uneven settlement in different terrains and work closely with the soil.

5. Lightweight: Lightweight, easy to transport, cut, and lay, greatly improving construction efficiency.

6. Filtration: While allowing water to pass through, it can prevent the loss of fine soil particles from upstream and downstream with water, thus preventing pipe surges.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy and hydropower engineering

Dam filtration and drainage: Geotextile is laid on the upstream slope of the dam to block soil particles from being washed away by water flow. At the same time, the accumulated water inside the dam is discharged through the pores of the fabric to prevent dam leakage and piping;

River regulation: Laying geotextile (often combined with geomembrane) on the slope of the river to protect the soil from water erosion, accelerate the drainage of slope water, and stabilize the slope shape.

2. Transportation Engineering

Roadbed isolation and reinforcement: Lay geotextile between roadbed fillers (such as gravel layer and plain soil layer) to isolate materials of different particle sizes, prevent "soil particles from mixing into the gravel layer and gravel from squeezing the plain soil layer", and enhance the overall tensile strength of the roadbed, reducing roadbed settlement;

Road surface drainage: Lay geotextile between the base and surface layers of the road surface to accelerate the drainage of rainwater from the road surface after it seeps into the base layer, and prevent rainwater from accumulating and causing road cracking and overturning.

3. Construction and Municipal Engineering

Underground garage/basement anti-seepage assistance: Lay geotextile between the waterproofing membrane and the base soil to protect the waterproofing membrane from being punctured by sharp soil particles, and assist in draining the accumulated water in the base layer;

Landfill site: Geotextile is laid above the anti-seepage membrane at the bottom of the landfill site as a "protective layer+filtering layer" to prevent impurities in the leachate from blocking the anti-seepage membrane, while guiding the leachate into the drainage system to prevent soil and groundwater pollution.

4. Environmental Protection and Ecological Engineering

Construction of artificial wetlands: laying geotextiles between the filling layers (such as gravel layers and soil layers) of artificial wetlands to filter suspended solids in sewage, while accelerating the internal water circulation of wetlands and improving sewage purification efficiency;

Slope greening: Lay geotextile under the greening substrate (such as nutrient soil) of rock slopes or barren slopes, fix the substrate without loss, and maintain the breathability and drainage of the substrate, providing a stable environment for plant growth.

5. Agricultural and Horticultural Engineering

Greenhouse drainage: Lay geotextile under the planting soil layer in the greenhouse to accelerate the discharge of excess water from the soil and prevent crop root rot;

Irrigation channels for farmland: Lay geotextile on the inner wall of the irrigation channel to reduce the erosion of soil by channel water flow and minimize channel leakage losses (water-saving rate can reach 15% -20%).

In summary, geotextile, as an efficient, economical, and environmentally friendly geosynthetic material, has become an indispensable key material in modern geotechnical engineering. Its application scope is still expanding with technological upgrades, such as composite geotextiles and smart geotextiles.