Geotextile Fabric Specifications and Properties Explained (ASTM Standards)

Introduction: Why Geotextile Specifications Matter in Engineering

In the world of geotechnical and civil engineering, a geotextile is in no way simply a piece of fabric. It is a precision-engineered fabric whose overall performance is quintessential to the sturdiness and steadiness of an whole project. Choosing the incorrect geotextile—or misunderstanding its specifications—can lead to catastrophic screw ups like soil contamination, drainage clogging, or slope collapse. The key to making an knowledgeable choice lies in perception the normal language of geotextile testing: the ASTM standards. This complete guide deciphers these fundamental specifications, empowering you to confidently consider a non woven needle punched geotextile for a pavement base or choose a high-strength woven geofabric for soil reinforcement. We will discover how these houses without delay have an effect on imperative features like geotextile drainage, making sure your task is constructed on a basis of knowledge.

The Foundation: Understanding ASTM International Standards

ASTM International, previously recognised as the American Society for Testing and Materials, develops and publishes voluntary consensus technical requirements for a enormous array of materials, which include geosynthetics. These requirements grant a consistent, repeatable methodology for checking out geotextile properties, permitting engineers, manufacturers, and contractors to examine merchandise on a stage taking part in field. When reviewing a product records sheet, the homes listed are nearly constantly derived from these ASTM tests. Ignoring these requirements is akin to constructing a residence barring a blueprint.

Key Physical Properties and Their Relevant ASTM Standards

Physical houses describe the basic, non-mechanical traits of the geotextile. These are regularly the first specs considered.

1. Mass per Unit Area (ASTM D5261)

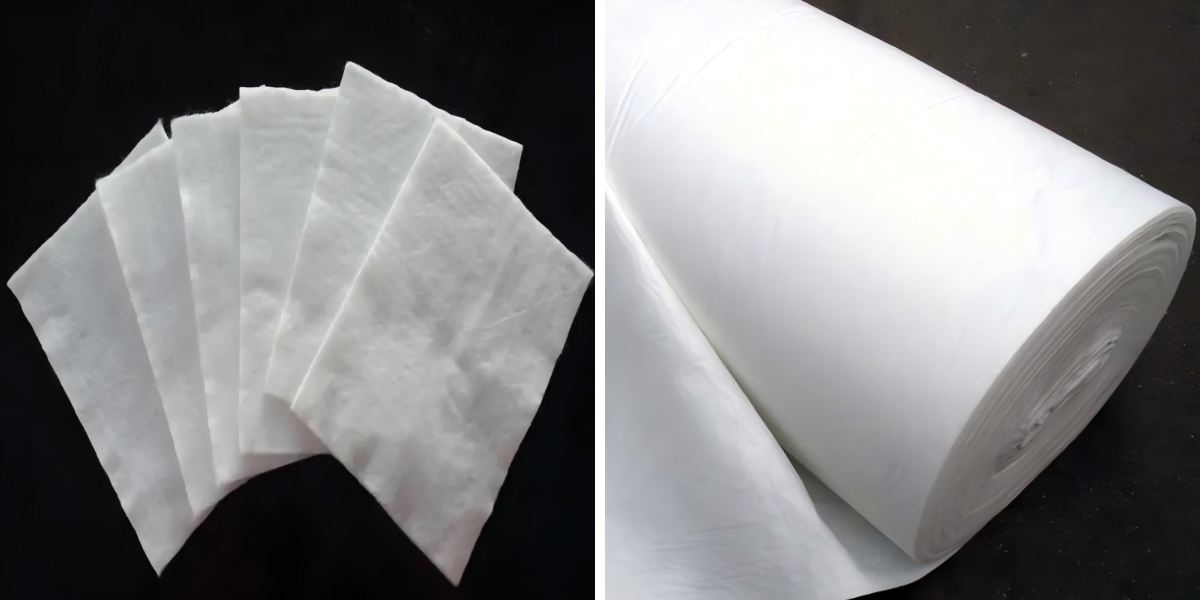

This take a look at without a doubt measures the mass of a geotextile per unit area, normally pronounced in oz. per rectangular yard (oz/yd²) or grams per rectangular meter (g/m²). While regularly used as a hard indicator of sturdiness and thickness, it have to now not be used on my own to predict performance. A heavier non woven needle punched geotextile usually shows extra fibers and a thicker matrix, which can be advisable for safety and filtration.

2. Thickness (ASTM D5199)

Thickness is measured below a particular strain (e.g., two kPa) and is said in millimeters. This property is imperative for functions the place the geotextile acts as a cushion or is worried in drift dynamics. For instance, the thickness of a non woven needle punched geotextile without delay influences its water storage potential and transmissivity, key elements in geotextile drainage design.

Critical Mechanical Properties: Measuring Strength and Durability

Mechanical homes outline how a geotextile responds to utilized forces. These are paramount for reinforcement and stabilization applications.

1. Wide-Width Tensile Strength and Elongation (ASTM D4595)

This is arguably the most necessary mechanical test. Unlike a easy snatch test, it makes use of a 200-mm vast specimen to decide the force-elongation relationship. It reviews the remaining tensile power (in kN/m or lb/in) and the stress (elongation) at that load. A woven geofabric commonly famous excessive tensile power with low elongation (less than 15%), making it perfect for soil reinforcement. In contrast, a non woven needle punched geotextile has decrease energy however greater elongation (often 50-80%), permitting it to conform to subgrade irregularities.

2. Trapezoid Tear Strength (ASTM D4533)

Tear energy measures a geotextile's capability to withstand the propagation of a tear as soon as it has been initiated. This is a essential property for survivability at some point of installation. If a rock punctures the fabric, a excessive tear power will forestall that small gap from turning into a massive rip beneath stress.

3. Puncture Strength (ASTM D6241)

This check measures the pressure required for a metallic probe to push thru the geotextile. It simulates the stress induced by way of sharp stones or particles in the subgrade. A strong non woven needle punched geotextile with excessive puncture resistance is imperative for defending refined geomembranes in landfill liners.

4. UV Resistance (ASTM D4355)

This fashionable exams the degradation of tensile electricity after a targeted duration of publicity to ultraviolet light. Geotextiles with negative UV resistance should be included quickly after installation. Most producers furnish merchandise with introduced UV stabilizers for prolonged uncovered durability.

Hydraulic Properties: The Key to Filtration and Drainage Performance

Hydraulic houses dictate how a geotextile interacts with water, making them the cornerstone of filtration and geotextile drainage design.

1. Apparent Opening Size (AOS) (ASTM D4751)

Previously acknowledged as Equivalent Opening Size (EOS), the AOS (reported in millimeters or U.S. Sieve Size) shows the approximate greatest opening in the geotextile. A decrease AOS fee potential smaller openings, which are higher for maintaining satisfactory soils. However, an AOS that is too small can hinder water drift and lead to clogging. Selecting the correct AOS is a balancing act between soil retention and permeability.

2. Permittivity and Permeability (ASTM D4491)

Permeability (kₙ) describes the geotextile's intrinsic capacity to transmit water below a hydraulic gradient, comparable to the permeability of soil.

Permittivity (Ψ) is a greater realistic property, described as the permeability divided by means of the thickness. It bills for the reality that water flows via the thickness of the fabric. Permittivity is the key property for designing a geotextile drainage or filtration system, as it shows the flow-through capability below a given head of water. A thick non woven needle punched geotextile normally has excessive water storage potential however its permittivity should be excessive ample to enable that water to glide out freely.

3. Flow Rate (ASTM D4491)

This take a look at at once measures the volume of water that passes via a geotextile beneath precise check conditions, imparting a direct overall performance metric for geotextile drainage applications.

Endurance Properties: Predicting Long-Term Performance

These houses examine how the geotextile will function over the lengthy time period underneath a number of environmental stresses.

1. Abrasion Resistance (ASTM D4886)

This check evaluates a geotextile's potential to stand up to sporting from contact with different materials, such as angular aggregate. It is essential for functions the place the material might also be issue to transferring soils or traffic.

2. Creep Behavior

While no longer a single ASTM standard, creep checking out entails subjecting a geotextile to a sustained load (e.g., 60% of its last strength) for an prolonged length to see how an awful lot it deforms. This is particularly necessary for a woven geofabric used in everlasting soil reinforcement, as it should preserve its electricity over a long time barring giant stretching.

Putting It All Together: Selecting Geotextiles by way of Application

Understanding specs is vain barring context. Here’s how these houses information choice for frequent applications.

For Separation and Stabilization: A non woven needle punched geotextile is regularly specified. Key houses consist of a sturdy puncture power (ASTM D6241) to forestall combination puncture, and a reasonable AOS (ASTM D4751) to stop soil pumping, whilst permitting for water motion to useful resource in geotextile drainage and consolidation.

For Soil Reinforcement: A high-strength woven geofabric is the standard. The most quintessential specification is the wide-width tensile power (ASTM D4595), which ought to be excessive with low elongation. Long-term graph strength, derived from creep discount factors, is used for design.

For Filtration and Drainage: Both woven and non-woven geotextiles can be used, however the hydraulic houses are paramount. The permittivity (ASTM D4491) have to be excessive adequate to permit free water passage, and the AOS (ASTM D4751) should be small ample to hold the soil particles, developing a filter cake. A non woven needle punched geotextile is regularly favored for its most reliable filtering skills with fine-grained soils.

Conclusion: Specifying with Confidence

Geotextile material specs are now not simply numbers on a page; they are a direct window into the material's overall performance and suitability for your project's special challenges. By learning the language of ASTM standards—from the tensile energy of a woven geofabric to the permittivity of a non woven needle punched geotextile for geotextile drainage—you cross from guessing to engineering.

Always require licensed take a look at reviews from producers that are based totally on these ASTM standards. This due diligence ensures that the geotextile you pick will function as intended, presenting a safe, durable, and inexpensive answer for the lifestyles of your project. When in doubt, seek advice from with a geotechnical engineer or an skilled geosynthetics dealer to bridge the hole between specification sheets and on-the-ground performance.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province