Geotech Fabric in Landfill Engineering: Key Functions and Installation Standards

Landfill engineering needs substances that can face up to harsh conditions, control complex waste dynamics, and adhere to strict environmental regulations. Among these materials, geotextile stands out as a linchpin, imparting multifaceted options that decorate safety, efficiency, and sustainability. From containing poisonous leachate to reinforcing unstable slopes, geotech cloth has come to be crucial in contemporary landfill design. This article delves into its crucial features and affords precise set up requirements to make sure most suitable performance.

1. Contamination Prevention: Safeguarding Soil and Groundwater

Landfills are hotspots for possible environmental contamination, with leachate— a poisonous liquid shaped by means of rainwater percolating via waste—posing giant dangers to soil and groundwater. Geotextile acts as a first line of defense, mitigating these dangers via its special filtration and barrier properties.

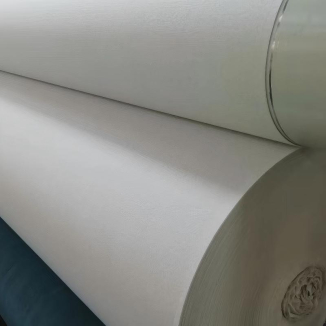

Nonwoven geotextile fabric is especially valued right here due to its dense, third-dimensional fiber structure. With pore sizes ranging from 0.01 to 0.5 mm, it correctly filters leachate, trapping damaging particles whilst permitting water vapor to escape. This prevents contaminants like heavy metals, unstable natural compounds (VOCs), and pathogens from seeping into the surrounding soil. In landfill liner systems, nonwoven geotextile fabric is regularly paired with high-density polyethylene (HDPE) geomembranes, the place it serves as a shielding cushion. This reduces the chance of membrane punctures from sharp waste fragments—such as damaged glass or metallic scraps—by distributing stress evenly. Studies exhibit that liners bolstered with nonwoven geotextile fabric trip 30% fewer leaks in contrast to unreinforced systems, making it a cost-efficient preference for long-term environmental protection.

2. Drainage Management: Controlling Leachate and Rainwater

Excess water in landfills is a essential concern: it will increase leachate volume, elevates strain on liners, and hastens waste decomposition—all of which can compromise structural integrity. Geotextile drainage fabric addresses this by means of growing environment friendly pathways for water flow, making sure appropriate drainage except sacrificing soil retention.

In landfill designs, geotextile drainage fabric is strategically mounted in two key areas: leachate series layers and perimeter drain systems. In leachate series layers, it is positioned atop a layer of gravel or sand, forming a composite machine that channels leachate towards series pipes. The permeability of geotextile drainage fabric—typically ranging from 1×10⁻³ to 1×10⁻¹ cm/s—allows for fast water movement, stopping pooling that may want to saturate waste and amplify smell emissions. Perimeter drains, lined with geotextile drainage fabric, redirect floor rainwater away from the landfill, lowering infiltration into the waste mass. This twin drainage strategy can decrease leachate therapy expenses through up to 25% by means of minimizing volume, whilst additionally decreasing the chance of liner failure due to hydrostatic pressure.

3. Soil Stabilization: Reinforcing Landfill Slopes and Foundations

Landfills regularly characteristic steep slopes and heavy waste loads, making soil stabilization a necessary protection priority. Geotextile enhances balance by way of reinforcing soil structure, distributing stress, and resisting erosion—even in difficult conditions.

Woven geotextile products, characterised via their excessive tensile energy (5–50 kN/m), are the cloth of preference for slope reinforcement. When hooked up horizontally inside slope layers, they act as "soil anchors," binding particles collectively and resisting the downward pull of gravity. This is particularly precious in the course of landfill expansion, the place new waste layers can exert lateral stress on current slopes. For example, in a 2022 challenge in Texas, woven geotextile was used to enhance a 30° landfill slope, lowering lateral displacement via 40% in contrast to regular methods. Geotextile also stabilizes landfill foundations by means of distributing the weight of waste evenly throughout the subsoil, stopping uneven agreement that may want to crack liners or harm drainage systems. In gentle soil conditions, this reinforcement can make bigger bearing potential by way of 50% or more, enabling safer, extra environment friendly waste stacking.

4. Separation of Materials: Maintaining Layer Integrity

Landfills are engineered as layered systems, with each layer—waste, soil cover, drainage media, and liners—serving a wonderful purpose. Geotextile acts as a separator, stopping cross-contamination between layers and retaining their functionality.

A frequent software is putting nonwoven geotextile fabric between the waste layer and the drainage layer. This prevents fantastic waste particles from migrating into the drainage gravel, which would in any other case clog pores and minimize water flow. In one case study, a landfill in California mentioned a 60% discount in drainage gadget preservation after imposing this separation strategy using nonwoven geotextile fabric. Geotextile also separates the soil cowl (used to comprise odors and deter pests) from the waste layer, stopping soil from compacting waste and inhibiting gasoline ventilation. By retaining clear boundaries between layers, geotextile extends the landfill’s operational life—often with the aid of 10–15 years—by making sure every issue features as designed.

5. Installation Standards for Optimal Performance

Even the highest-quality geotextile will underperform barring perfect installation. Adhering to these requirements ensures most effectiveness:

Site Preparation: Before installation, clear the vicinity of debris, rocks large than 5 cm, and vegetation. Use a curler to compact the subsoil to a density of 90–95% of its most dry density, developing a smooth, steady base. This minimizes the chance of punctures and ensures uniform contact between the geotextile and soil.

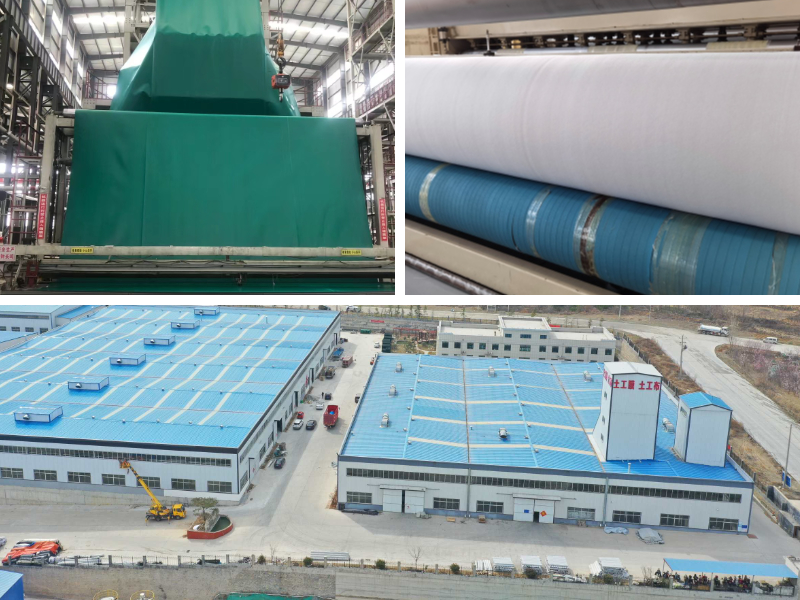

Material Handling: Store geotextile rolls on pallets in a shaded, included place to guard from UV radiation, which can degrade fibers over time. When transporting, keep away from dragging rolls—use forklifts or cranes to stop tearing. For nonwoven geotextile fabric, take care of with care to keep away from stretching, which can alter pore sizes.

Overlap and Seaming: Overlap sheets of geotextile by using 30–60 cm (12–24 inches) in high-stress areas (e.g., slopes) and 30 cm in flat areas. For indispensable zones like liner systems, use warmness welding (for thermoplastic geotextile) or needle punching (for nonwoven geotextile fabric) to create watertight seams. Test seams with a vacuum or strain take a look at to make certain integrity.

Coverage and Securing: Unroll geotextile parallel to the slope’s contour to decrease wrinkles. Use sandbags (20–30 kg each) or soil anchors (spaced 1–2 meters apart) to tightly closed the fabric, in particular on slopes higher than 20°. Avoid overstretching, as this can limit tensile strength.

Conclusion

Geotech material is a cornerstone of modern-day landfill engineering, imparting unparalleled options for infection prevention, drainage, stabilization, and cloth separation. Whether the usage of nonwoven geotextile fabric for filtration or geotextile drainage fabric for water management, its versatility makes it indispensable. By following strict set up standards—from website online instruction to seaming—engineers can make certain geotextile performs at its best, decreasing environmental dangers and extending landfill lifespans. As international waste volumes upward jab and policies tighten, the position of geotextile in sustainable landfill layout will solely grow, solidifying its popularity as a fundamental fabric for a greener future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province