Dewatering Bags for Construction Sites: A Step-by-Step Implementation Guide

Introduction to Dewatering Bags

In the realm of building projects, nice dewatering is of utmost importance. Excess water on a development website can lead to severa issues, such as soil instability, tools damage, and delays in the development process. Dewatering is the manner of getting rid of water from the development area, making sure a dry and secure working environment.

This is the place Dewatering Bags come into play. Dewatering Bags are specialised containers designed to separate water from solids, making them an integral device in building dewatering operations. These luggage are made from excessive - strength, permeable substances that permit water to ignore via whilst keeping sediment and different stable particles.

They are typically used in a range of development scenarios. For example, in giant - scale infrastructure initiatives like constructing bridges or roads, Dewatering Bags are used to control the water that accumulates in excavations. In land reclamation projects, they assist in isolating the water from the dredged materials, facilitating the introduction of new land. In addition, in building websites close to water our bodies such as rivers or lakes, Dewatering Bags are vital for controlling the influx of water and preserving the integrity of the development area. Their versatility and effectiveness have made them a famous preference amongst building gurus for dewatering tasks, and they frequently work in tandem with different equipment like Sedimentation Tubes for Dredging Projects to make certain a complete answer for water administration in construction.

The Function and Benefits of Dewatering Bags

Function

Dewatering Bags function on a simple but especially positive principle. Made from specialised geotextile materials, these luggage act as a bodily barrier between water and solids. When the water - encumbered combination is poured into the Dewatering Bag, the geotextile cloth lets in water molecules to skip thru its tiny pores due to the pressure of gravity and hydrostatic pressure. This manner is comparable to how a espresso filter approves water to seep thru whilst holding the espresso grounds.

For instance, in a development website online the place the soil has been excavated and is blended with groundwater, when this muddy combination is positioned in a Dewatering Bag, the water starts offevolved to slowly drain out, leaving the soil particles trapped inside. The special porosity of the bag's fabric is cautiously engineered to make certain that solely water and very satisfactory particles that are smaller than the pore dimension can escape, efficaciously isolating the two components. This filtration technique is non-stop as lengthy as there is a water - strong combination existing in the bag and the crucial strain differential exists.

Benefits

1. Efficient Dewatering

Dewatering Bags provide a notably environment friendly answer for water removal. They can deal with massive volumes of water - weighted down substances in a exceptionally quick period. In evaluation to some common dewatering methods, such as the use of easy sieves or relying on herbal drainage, Dewatering Bags can substantially velocity up the dewatering process. In a giant - scale dredging project, Sedimentation Tubes for Dredging Projects are frequently used in conjunction with Dewatering Bags. The sedimentation tubes first enable the large sediment particles to settle, and then the last water - sediment combination can be in addition processed by using Dewatering Bags. This combination ensures that the dewatering technique is no longer solely environment friendly however additionally thorough, decreasing the typical time required for the project.

2. Cost - effectiveness

In phrases of cost, Dewatering Bags are an fascinating option. They are usually extra less expensive than some complex mechanical dewatering equipment. Additionally, their simplicity in operation skill that much less manpower and fewer sources are wished for their use. There is no need for complicated equipment set - up, maintenance, or extraordinarily professional operators. Once mounted as per the Geotube Installation Guide (since geotubes are a kind of giant - scale Dewatering Bag), they can function with minimal supervision, lowering labor charges over the direction of a building project.

3. Environmental Friendliness

From an environmental perspective, Dewatering Bags are a sustainable choice. By correctly keeping apart solids from water, they stop the launch of sediment - weighted down water into close by water bodies, which ought to in any other case purpose water air pollution and damage aquatic ecosystems. The retained solids can be suitable disposed of or reused, relying on their nature. For example, in some development projects, the dewatered soil can be used for backfilling or land - shaping purposes. This now not solely reduces the environmental affect however additionally aligns with the standards of sustainable construction.

4. Versatility

Dewatering Bags are incredibly versatile and can be used in a large vary of development and industrial applications. They can deal with one of a kind kinds of water - stable mixtures, whether or not it is muddy soil, sludge from wastewater remedy plants, or dredged substances from rivers and lakes. Their adaptability makes them appropriate for initiatives of a number scales, from small - scale residential development to giant - scale infrastructure developments.

Step - by using - Step Implementation of Dewatering Bags

Site Preparation

Before putting in Dewatering Bags, thorough website training is crucial. First, the development location desires to be cleared of any debris, rocks, or different limitations that ought to doubtlessly harm the baggage at some point of set up or operation. This consists of putting off giant - sized building waste, tree stumps if the web site was once until now a vegetated area, and any free substances that may want to be swept into the dewatering system.

Next, the vicinity for setting the Dewatering Bags need to be cautiously determined. This entails thinking about elements such as the supply of the water - encumbered material, the slope of the land, and the proximity to different building activities. For example, if the water is coming from an excavation site, the Dewatering Bags need to be positioned at a decrease elevation to take gain of gravity for the dewatering process. In addition, the vicinity ought to be incredibly flat to make certain the balance of the baggage when they are stuffed with the water - stable mixture. Mark the set up location certainly the use of stakes or spray paint to information the subsequent set up work.

Dewatering Bag Installation

1. Unfolding the Bags

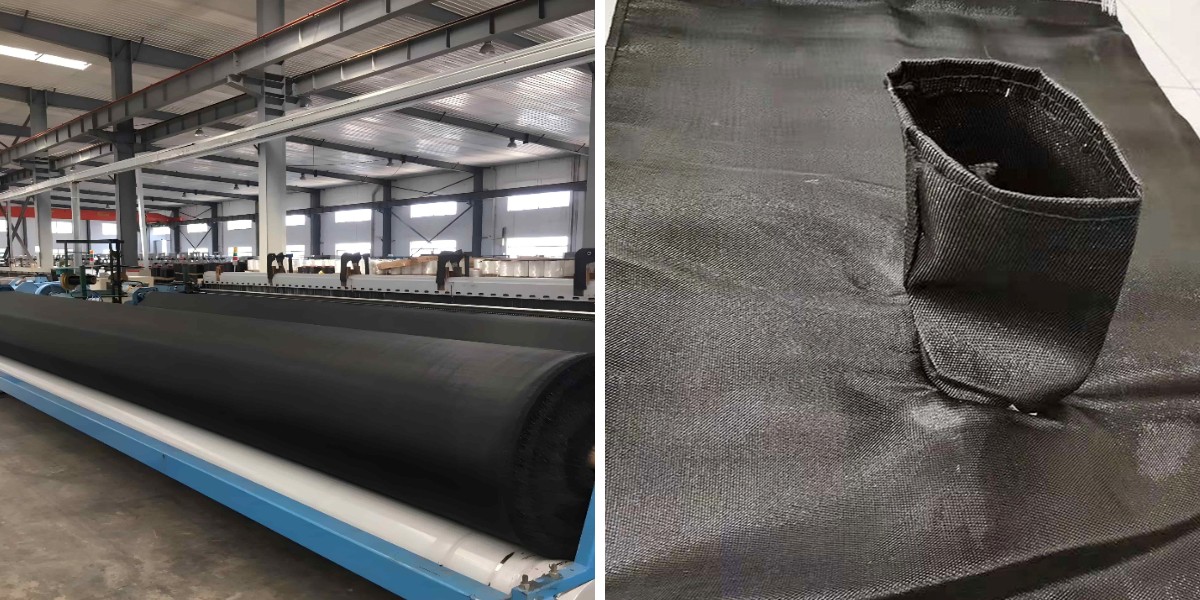

Begin by way of cautiously unpacking the Dewatering Bags. Unfold them gently to keep away from any tearing or injury to the geotextile material. If the baggage have been tightly rolled or folded at some stage in transportation, take your time to straighten them out completely. For large - sized Dewatering Bags, which are frequently used in industrial or giant - scale building projects, it may also require a couple of employees to deal with the unfolding manner safely.

2. Positioning and Fixing

Once unfolded, role the luggage in the pre - marked area. Ensure that the bags are positioned in a way that lets in for convenient get right of entry to to the water - weighted down cloth source. For example, if the water is being pumped from a sump, the bag's inlet have to be shut to the pump outlet for environment friendly filling. After positioning, invulnerable the luggage in place. This can be achieved the use of stakes, sandbags, or different appropriate anchoring methods. Stakes have to be pushed into the floor round the perimeter of the bag, mainly at the corners, to stop the bag from moving throughout the filling process. Sandbags can be positioned alongside the edges of the bag to add extra weight and stability, specially in areas with sturdy winds or the place there may additionally be some motion of the ground.

3. Filling the Bags

Connect the hose or pipe from the supply of the water - strong combination to the inlet of the Dewatering Bag. Start the go with the flow of the combination slowly to enable the bag to steadily extend and adjust. Monitor the filling method intently to stop over - filling. Over - filling can reason the bag to burst or put immoderate stress on the anchoring points. As the bag fills, the water will begin to drain thru the geotextile fabric, and the solids will be retained inside. The filling fee can also differ relying on the kind of material, the dimension of the bag, and the pumping capacity.

During the set up process, it is vital to observe security precautions. Workers need to put on suitable private defensive equipment, such as gloves, protection boots, and challenging hats. Also, be conscious of the achievable for slippery stipulations round the dewatering location due to the presence of water.

Connecting with Sedimentation Tubes (Optional)

In some dredging and massive - scale development projects, Dewatering Bags can be efficiently used in aggregate with Sedimentation Tubes for Dredging Projects. The sedimentation tubes are generally hooked up upstream of the Dewatering Bags. These tubes work with the aid of permitting the water - sediment combination to glide thru them, and due to the large move - sectional vicinity and the precept of sedimentation, the heavier sediment particles settle down inner the tubes.

The connection between the sedimentation tubes and the Dewatering Bags is generally made the use of bendy hoses or pipes. The outlet of the sedimentation tube is linked to the inlet of the Dewatering Bag. This setup gives a number of advantages. Firstly, it reduces the load on the Dewatering Bags through pre - keeping apart the large sediment particles in the sedimentation tubes. This capability that the Dewatering Bags can center of attention on similarly setting apart the finer particles and water, enhancing the universal effectivity of the dewatering process. Secondly, it helps in higher administration of the sediment, as the large sediment can be greater effortlessly eliminated from the sedimentation tubes for perfect disposal or reuse. For example, in a river dredging project, the coarser sediment that settles in the sedimentation tubes can be used for land - filling in non - touchy areas, whilst the water and finer sediment that skip thru to the Dewatering Bags can be in addition processed to meet environmental discharge standards.

Monitoring and Maintenance

Once the Dewatering Bags are set up and operational, everyday monitoring and preservation are necessary to make sure their persevered effectiveness. Monitoring is indispensable for early detection of any problems that may want to have an effect on the dewatering process.

Regular Inspections

Regularly look at the Dewatering Bags for signs and symptoms of put on and tear. This consists of checking the geotextile cloth for any holes, tears, or punctures. Even a small gap can compromise the dewatering efficiency, as solids might also begin to leak out alongside with the water. Use a visible inspection method, taking walks round the baggage and searching carefully at the surface. Pay exclusive interest to the areas round the inlet and outlet, as these are the components that trip the most stress for the duration of the filling and draining processes. Additionally, test the anchoring factors to make positive the baggage are nonetheless firmly in place. Loose anchoring can motive the luggage to shift, which may additionally lead to uneven filling or injury to the bags.

Performance Checks

To decide if the Dewatering Bags are working properly, reveal the price of water drainage. If the water is now not draining as rapidly as expected, it may want to point out a blockage in the geotextile pores or an difficulty with the supply of the water - stable mixture. For example, if the combination has a excessive attention of first-class - grained materials, it may additionally clog the pores over time. Compare the contemporary drainage fee with the predicted fee based totally on the kind of fabric being dewatered and the specs of the Dewatering Bags. Also, take a look at the consistency of the dewatered fabric interior the bag. If it is too wet, it ability that the dewatering procedure is no longer as environment friendly as it need to be, and in addition investigation is needed.

Maintenance Tips

1. Cleaning

Periodically smooth the Dewatering Bags, specially if they have been used with substances that have a tendency to stick to the geotextile fabric. A mild wash with water can assist do away with any accrued debris or sediment on the surface. Avoid the usage of harsh chemicals, as they might also injury the geotextile material. For cussed stains or construct - up, a tender brush can be used to gently scrub the floor whilst rinsing with water.

2. Replacing Damaged Parts

If any section of the Dewatering Bag is damaged, such as a torn area of the material or a damaged inlet/outlet connection, it have to be changed immediately. For small tears, a patch package mainly designed for geotextile substances can be used to restore the damage. However, for large or extra sizable damage, it is really helpful to substitute the complete bag. In the case of troubles with the anchoring system, change any damaged stakes or broken sandbags to make sure the balance of the bag. By following these monitoring and renovation practices, the lifespan and effectivity of the Dewatering Bags can be notably enhanced, contributing to the ordinary success of the building project. This everyday renovation additionally ensures that the baggage work in concord with different factors like Sedimentation Tubes for Dredging Projects, if they are section of the average dewatering system, and that the whole setup adheres to the concepts of the Geotube Installation Guide for greatest performance.

Geotube Installation Guide (If Related)

Geotubes are in reality massive - scale Dewatering Bags, regularly used in extra industrial - scale purposes such as giant - scale dredging projects, coastal protection, and land reclamation. They are made from comparable geotextile substances however are a lot large in size, succesful of preserving massive quantities of water - encumbered sediment.

Installation Steps

1. Site Assessment and Planning

Just like with everyday Dewatering Bags, a targeted web site evaluation is crucial. Determine the graph of the geotubes based totally on the glide of water, the topography of the area, and the quantity of sediment to be processed. For example, in a coastal vicinity the place geotubes are used for seashore nourishment, the set up region need to be cautiously chosen to make sure that the stuffed geotubes will efficiently defend the shoreline from erosion and additionally mixture in with the herbal seaside profile. Calculate the wide variety and dimension of geotubes required in accordance to the project's precise needs.

2. Laying the Foundation

Prepare a clean and steady basis for the geotubes. This may also contain leveling the ground, doing away with sharp objects, and in some cases, laying a layer of protecting geotextile on the ground. The defensive geotextile helps forestall the geotubes from being punctured by using any underlying particles and additionally affords an extra layer of separation between the geotubes and the ground.

3. Unrolling and Connecting Geotubes

Unroll the geotubes carefully, taking into account their massive measurement and weight. In some cases, heavy - obligation equipment such as cranes or bulldozers may additionally be required to manage the unrolling process. If more than one geotubes are wished to cowl a giant area, they want to be linked properly. Special connectors or overlapping strategies are used to make certain a tight seal between adjoining geotubes. This connection is essential to stop leakage of sediment - weighted down water between the geotubes for the duration of the filling process.

4. Filling the Geotubes

Use pumps or different hydraulic structures to fill the geotubes with the water - sediment mixture. The filling procedure have to be monitored intently to make certain an even distribution of the combination inner the geotube. Uneven filling can lead to an imbalance in the geotube's structure, doubtlessly inflicting it to give way or shift. The filling charge have to additionally be adjusted in accordance to the energy and potential of the geotube material.

Installation Points

1. Material Compatibility

Ensure that the geotube cloth is well matched with the kind of sediment and water it will be handling. For example, if the sediment has a excessive salt content, as in seawater - associated projects, the geotextile cloth must be resistant to salt corrosion to preserve its integrity over time.

2. Anchoring and Stability

Due to their massive dimension and the forces performing on them, suited anchoring of geotubes is essential. Anchoring techniques can encompass the use of giant - scale stakes, anchors pushed deep into the ground, or connecting the geotubes to current structures. In areas with sturdy water currents or wave action, extra measures may additionally be wanted to make certain the geotubes continue to be in place. This ought to contain the usage of a grid - like device of ropes or cables to tie the geotubes collectively and to constant factors on the shore or seabed. By following these Geotube Installation Guide steps and paying interest to the key set up points, geotubes can be efficaciously established and built-in into the universal dewatering and sediment administration system, regularly working in concord with smaller Dewatering Bags and Sedimentation Tubes for Dredging Projects to attain the project's goals.

Conclusion

In conclusion, Dewatering Bags are an helpful asset in development projects. Their capability to correctly separate water from solids affords a realistic answer to the frequent trouble of extra water on building sites. From stopping soil instability to lowering environmental impact, the advantages of the usage of Dewatering Bags are a ways - reaching.

The step - via - step implementation process, from web page coaching to everyday monitoring and maintenance, ensures that these luggage feature optimally. When necessary, the integration of Sedimentation Tubes for Dredging Projects and following the Geotube Installation Guide (for large - scale applications) can similarly beautify the dewatering process.

If you are planning a building assignment and are thinking about dewatering solutions, we especially motivate you to discover the use of Dewatering Bags. They provide a price - effective, environmentally friendly, and environment friendly way to control water on your site. Should you have any questions involving Dewatering Bags, their installation, or how they can be tailor-made to your particular undertaking needs, please do not hesitate to contact us. Our group of specialists is prepared to grant you with extra facts and aid you in making the excellent preference for your development project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province