HDPE vs. PP Geocells: Material Comparison for Slope Protection Projects

When it comes to geocell slope protection, determining on the perfect cloth is make-or-break for mission sturdiness and cost-effectiveness. High-density polyethylene (HDPE) and polypropylene (PP) are the two most customary polymers used in geocell manufacturing, every with distinctive residences that go nicely with super slope conditions. Whether you’re stabilizing a toll street embankment, residential hillside, or coastal slope, perception how HDPE and PP geocells feature can aid you select the nice option. This statistics compares the two supplies at some point of key factors—durability, flexibility, environmental resistance, and cost—while highlighting the function of picks like Basecore Geocell in present day geocell for slope security projects. By the end, you’ll be in a role to healthful the ideal geocell material to your slope’s unique needs.

The Basics: What Are HDPE and PP Geocells?

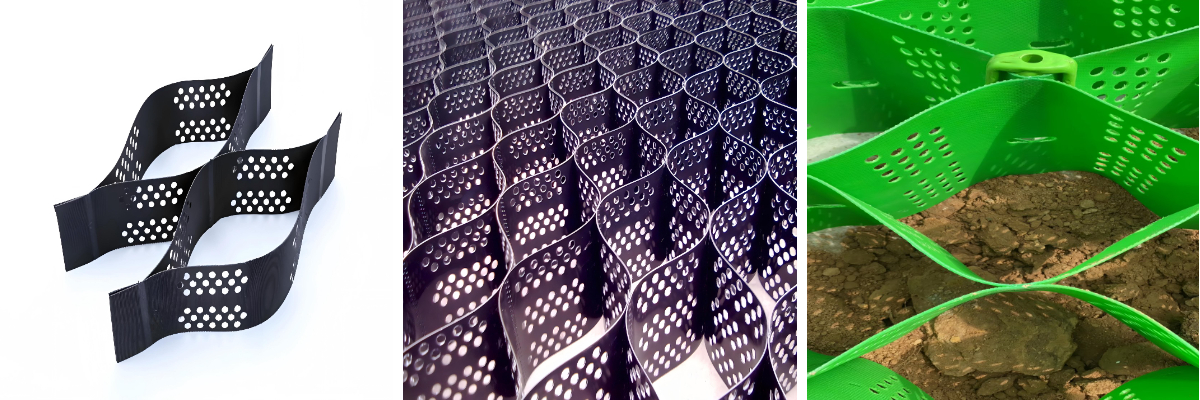

Both HDPE and PP geocells are three-dimensional, honeycomb-like constructions designed to confine soil, gravel, or vegetation for geocell slope protection. They arrive flat, enlarge into rigid grids on-site, and create a reinforced composite system that boosts soil shear electricity and prevents erosion. The core big difference lies in their polymer composition:

HDPE (high-density polyethylene) is a dense, crystalline polymer diagnosed for its electrical energy and rigidity. It’s generally used in lengthy lasting merchandise like plastic pipes and containers. PP (polypropylene) is a lighter, more flexible polymer with real have an effect on resistance, regularly found in packaging and textiles. In geocell form, these editions translate to notable normal overall performance characteristics for geocell for slope protection.

Solutions like Basecore Geocell often leverage HDPE for high-stress applications, on the other hand PP variants are moreover accessible for duties the location flexibility is prioritized. Understanding their nuances ensures you don’t overengineer (or underengineer) your slope protection system.

Durability: HDPE’s Rigidity vs. PP’s Flexibility

Durability is non-negotiable for geocell slope protection, as slopes face constant stress from soil movement, water runoff, and temperature fluctuations. Here’s how the two supplies stack up:

HDPE Geocells: Long-Term Rigidity

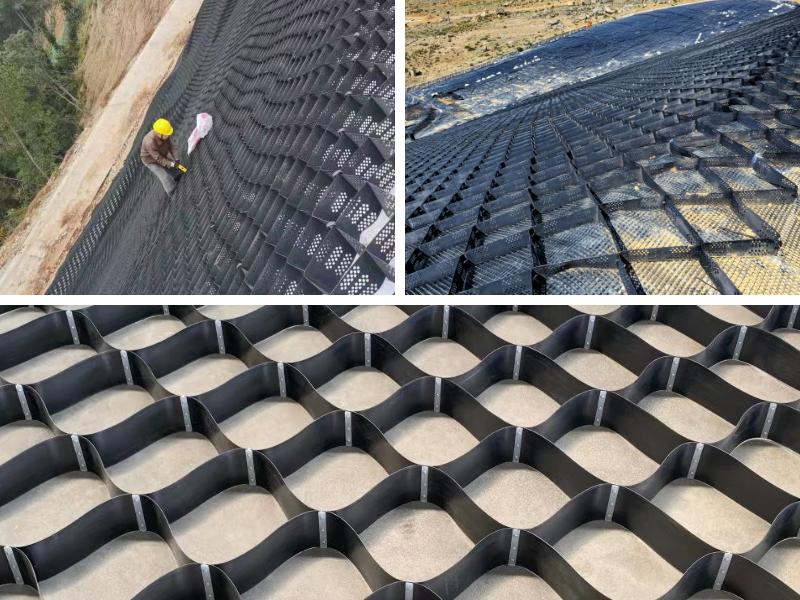

HDPE geocells excel in long-term sturdiness thanks to their immoderate tensile power and resistance to deformation. They hold their shape even below heavy thousands or prolonged soil pressure, making them ideal for eternal geocell for slope safety duties (e.g., twin carriageway embankments or industrial internet web site slopes). HDPE’s dense form moreover resists punctures from rocks or debris, lowering the danger of grid failure.

Products like Basecore Geocell (typically HDPE-based) are engineered to face up to many years of publicity without widespread degradation. This sturdiness is integral for slopes that require minimal renovation over time, as HDPE geocells won’t stretch or sag under the weight of overlying soil or vegetation.

PP Geocells: Flexible Resilience

PP geocells supply greater flexibility than HDPE, enabling them to conform to irregular slope surfaces (e.g., rocky hillsides or curved embankments). Their flexibility makes them higher resistant to impact damage—they can take in minor shocks (like falling debris) barring cracking. However, PP is more inclined to creep (slow deformation beneath regular load) than HDPE, which functionality it may additionally moreover stretch barely over time on steep or carefully loaded slopes.

For short or medium-term geocell slope security (e.g., constructing internet site on line slopes that will be redeveloped), PP geocells are a practical choice. Their flexibility simplifies set up on uneven terrain, and they nonetheless furnish reliable erosion manipulate for the project’s duration.

Environmental Resistance: How They Stand Up to the Elements

Slope protection geocells face harsh environmental conditions—UV radiation, moisture, and chemical exposure—so material resistance is key.

UV and Weather Resistance

HDPE has perfect UV resistance in distinction to PP. Without stabilizers, PP degrades faster in direct sunlight, turning into brittle and shedding electricity over time. HDPE, with the aid of ability of contrast, retains its residences even after years of photo voltaic exposure, making it the greater choice for open, unshaded slopes. Most PP geocells embody UV stabilizers to mitigate this issue, on the other hand their long-term resistance however lags at the again of HDPE.

In moist environments (e.g., coastal slopes or moist regions), every supplies stand up to water absorption, then again HDPE’s density makes it greater resistant to swelling or warping. This is why Basecore Geocell and extraordinary HDPE merchandise are favored for slopes with immoderate rainfall or groundwater levels.

Chemical Resistance

HDPE and PP every stand up to most commonplace soil chemical compounds (e.g., fertilizers, acids, and alkalis), on the other hand HDPE has a average section in harsh industrial settings. For slopes shut to factories or agricultural areas the region chemical runoff is possible, HDPE geocells furnish delivered peace of mind. PP geocells are however excellent for most residential or industrial geocell for slope protection projects, as they cope with everyday soil chemistry barring issue.

Installation and Cost: Balancing Ease and Budget

Installation complexity and cost regularly influence fabric choice, in precise for large-scale slope projects.

Installation Ease

PP geocells are lighter and more flexible than HDPE, making them much less problematic to transport and unroll on-site. Their flexibility lets them contour to uneven slopes without requiring vast internet site on-line preparation, lowering set up time and labor costs. HDPE geocells, whilst stiffer, are however manageable to install—especially with merchandise like Basecore Geocell that characteristic interlocking designs for rapid assembly. However, they can additionally choose increased unique internet site on-line grading to make certain a flat ground for expansion.

Cost Considerations

PP geocells are oftentimes increased low price upfront than HDPE, making them fascinating for budget-constrained projects. However, HDPE’s longer lifespan and minimize renovation needs regularly give up end result in greater long-term value. For eternal geocell slope protection, the larger preliminary fee of HDPE is offset through the use of fewer replacements or repairs over time. PP is a competitively priced wish for quick slopes or duties the location lifespan is a lot much less critical.

Which Material Is Right for Your Geocell Slope Protection Project?

Use this breakdown to wholesome material to mission needs:

Choose HDPE Geocells If:

You desire eternal geocell for slope protection (10+ years).

The slope is steep, intently loaded, or uncovered to direct sunlight.

You prioritize long-term sturdiness and minimal maintenance.

The project entails harsh environmental conditions (coastal, industrial, or high-rainfall areas).

Solutions like Basecore Geocell are pleasant here, as they maximize HDPE’s strengths for necessary slope protection.

Choose PP Geocells If:

The task is transient or medium-term (1-5 years).

The slope has irregular terrain or curves that require flexibility.

Budget is a pinnacle priority, and UV publicity is restricted (e.g., shaded slopes).

You desire fast, handy set up with minimal internet web page preparation.

Conclusion: Material Matters for Slope Success

HDPE and PP geocells every furnish excessive first-rate geocell slope protection, then again their one-of-a-kind properties make them greater ideal for special scenarios. HDPE guarantees long-term stress and environmental resistance for permanent, high-stress slopes—with merchandise like Basecore Geocell putting the favored for durability. PP affords flexibility and affordability for quick or irregular slopes, the vicinity ease of set up and price range are key.

By evaluating your project’s lifespan, slope conditions, and budget, you can select the suitable fabric to make sure your geocell for slope protection gadget is strong, reliable, and cost-effective. Remember: the outstanding geocell isn’t really the most steeply-priced or the most flexible—it’s the one that aligns with your slope’s distinctive desires for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province