Design and Engineering Considerations for Geotextile Tube Structures

Geotextile tube buildings have revolutionized coastal, environmental, and geotechnical engineering. These versatile dewatering and containment options provide a low-cost and environmentally pleasant choice to ordinary strategies like sandbags or inflexible structures. However, their success hinges on meticulous design, unique cloth selection, and rigorous execution. This article delves into the imperative engineering concerns for deploying sturdy and nice geotextile tube systems.

Understanding the Core Function of Geotextile Tubes

At their simplest, a geotextile tube is a large, elongated container made from high-strength, permeable artificial fabrics. They are stuffed with a slurry—often dredged sediment, contaminated sludge, or agricultural waste. The cloth acts as a filter, permitting water to get away whilst holding the stable particles. This process, recognized as dewatering, outcomes in a stable, solid-filled shape used for:

Shoreline Protection and Erosion Control: Acting as breakwaters, revetments, and groynes.

Decontamination and Dewatering: Treating industrial and agricultural waste, and municipal sludge.

Land Reclamation and Containment Dikes:Creating new land or containment barriers.

The effectiveness of any venture the usage of this science is a direct end result of three pillars: acceptable design, suitable Geotube Material Specifications, and adherence to geotube dewatering quality practices.

Key Design and Engineering Parameters

The diagram segment is the most vital step in ensuring the structural integrity and durability of a geotextile tube installation. Engineers ought to analyze a complicated interaction of factors.

1. Site-Specific Conditions and Load Analysis

Before a single geotextile tube is placed, a thorough web page investigation is mandatory. This includes:

Hydrodynamic Forces: For marine applications, wave height, period, modern velocity, and tidal levels need to be analyzed to decide the hydraulic hundreds on the structure.

Geotechnical Properties: The bearing ability and shear power of the underlying soil are essential to forestall subsidence or sliding. Slope balance evaluation is regularly required.

Environmental Exposure: UV radiation, temperature extremes, and possible for vandalism or abrasion impact both plan and fabric selection.

2. Determining Geotextile Tube Geometry and Filling Strategy

The ultimate dimensions of a geotextile tube are no longer arbitrary. They are a characteristic of the fill material, accessible space, and meant function. Engineers calculate the required circumference and size to obtain the preferred top and volume. The filling strategy—whether single-stage or multi-stage filling—is deliberate to manipulate the inner stresses and make certain the shape achieves its designed shape. This planning is intrinsically linked to the subsequent geotube dewatering fantastic practices that will be employed.

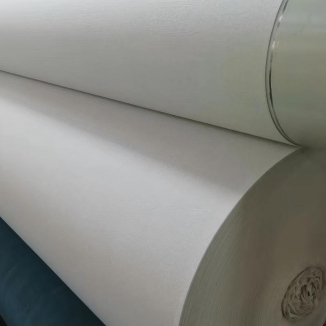

Selecting the Right Geotube Material Specifications

The cloth is the very coronary heart of the system. Selecting the right Geotube Material Specifications is a non-negotiable thing of engineering that balances strength, permeability, and durability.

1. Tensile Strength and Seam Integrity

The cloth need to face up to the giant hydraulic pressures in the course of pumping and the long-term static masses as soon as filled. Key Geotube Material Specifications for power include:

Wide-Width Tensile Strength: Measured in kN/m, this shows the pressure required to rupture the material in the cross-machine and computer directions. The required energy is calculated primarily based on the inside stress from the fill slurry.

Seam Strength: The seams are regularly the weakest point. The seam efficiency—the power of the seam as a proportion of the mother or father material strength—must be distinctive to be excessive (typically >90%) to stop catastrophic failure throughout filling.

2. Permittivity and Filtration Efficiency

The principal feature of the cloth is to dewater the slurry. The applicable Geotube Material Specifications right here are:

Permittivity (ψ): This is the fabric's capacity to enable water to glide via it underneath a head differential. A permittivity that is too low will gradual dewatering, whilst one that is too excessive may additionally enable satisfactory particles to escape.

Apparent Opening Size (AOS): This controls the filtration efficiency, identifying the dimension of particles retained interior the geotextile tube. The AOS should be fantastic ample to hold the solids however open adequate to forestall blinding (pore clogging).

3. Durability and Survivability

The cloth should undergo set up stresses and long-term environmental exposure. Critical Geotube Material Specifications for sturdiness include:

UV Resistance: The cloth ought to be manufactured with carbon black or different UV stabilizers to stop degradation from sunlight, particularly earlier than and after filling.

Abrasion Resistance: This is integral for purposes the place the geotextile tube will be subjected to wave motion or bodily contact.

Puncture Strength: The capability to withstand harm from sharp objects at some point of placement or from inside the fill fabric itself.

Implementing Geotube Dewatering Best Practices

Even a flawlessly designed geotextile tube made from best substances can underperform if suitable filling and dewatering methods are now not followed. Adhering to geotube dewatering exceptional practices ensures efficiency, safety, and challenge success.

1. Slurry Characterization and Conditioning

The nature of the slurry immediately influences the dewatering fee and remaining solids content. Key geotube dewatering great practices begin with grasp the slurry's particle dimension distribution and solids concentration. In some cases, chemical conditioners (flocculants or polymers) are delivered to the slurry to coagulate fantastic particles, developing large flocs that dewater extra unexpectedly and efficiently, lowering the manageable for material blinding.

2. Controlled Filling and Water Management

Filling ought to be a controlled, phased process.

Phased Filling: The geotextile tube is stuffed to a partial peak and allowed to dewater for a length (e.g., 12-24 hours) earlier than the subsequent filling cycle. This prevents over-pressurization and approves the cloth to consolidate the solids, constructing a steady inner filter cake.

Managing Effluent: The water that drains out (effluent) need to be managed. Sediment ponds or extra filtration may additionally be required to meet environmental discharge standards, a necessary element of accountable geotube dewatering great practices.

3. Monitoring and Maintenance

Active monitoring at some stage in the filling manner is essential. Engineers ought to song the go with the flow rate, pressure, and quantity of the injected slurry. After filling, the shape have to be inspected generally for any symptoms of damage, and the surrounding vicinity ought to be checked for stability. Properly grasp the relationship between the preliminary Geotube Material Specifications and the located discipline overall performance is key to refining future projects.

Conclusion: An Integrated Approach is Key

The profitable implementation of a geotextile tube undertaking is a symphony of interdisciplinary engineering. It requires the seamless integration of geotechnical analysis, hydraulic modeling, and specific fabric science. There is no room for compromise; choosing the right Geotube Material Specifications varieties the foundation, whilst diligent execution of geotube dewatering exceptional practices ensures the shape performs as intended. By respecting these quintessential layout and engineering considerations, challenge managers and engineers can leverage this effective science to construct resilient, sustainable, and good value options for some of the world's most urgent environmental and infrastructural challenges.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province