Using HDPE Geomembrane for Mine Tailings Storage: Safety and Compliance Tips

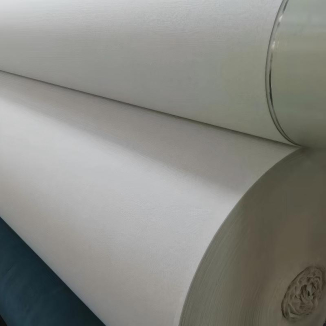

Mine tailings— the waste byproducts of mining operations— pose sizeable environmental and protection dangers if now not contained properly. Leaks from tailings storage amenities (TSFs) can contaminate soil, groundwater, and close by water bodies, main to long-term ecological harm and felony penalties. This is the place HDPE Geomembrane emerges as a imperative solution: its durability, chemical resistance, and impermeability make it the gold widespread for securing tailings. Below, we wreck down key security and compliance guidelines for the use of HDPE Geomembrane in mine tailings storage, protecting cloth selection, installation, regulatory alignment, and long-term maintenance.

1. Prioritize High-Quality HDPE Geomembrane Selection: The Foundation of Safety

Not all Geomembrane merchandise are equal— selecting the proper HDPE variant is the first step to making sure TSF integrity. Low-quality or mismatched geomembranes can degrade prematurely, main to leaks and compliance failures. When deciding on HDPE Geomembrane for tailings storage, center of attention on the non-negotiable standards outlined below.

1.1 Key Quality Checks for HDPE Geomembrane

Opt for HDPE Geomembrane made from virgin high-density polyethylene (HDPE) resin alternatively than recycled or blended materials, as virgin HDPE presents top-quality resistance to the acidic, alkaline, or heavy-metal-laden fluids frequent in mine tailings, whilst recycled resins may additionally include impurities that weaken the geomembrane’s shape over time; for mine tailings, pick HDPE Geomembrane with a minimal thickness of 1.5 mm (60 mils), with thicker membranes (2.0 mm or eighty mils) best for high-risk websites with heavy tailings masses or harsh climates due to their capability to face up to punctures from rocks and face up to intense temperatures (from -40°C to 60°C); additionally, affirm that the HDPE Geomembrane meets enterprise requirements like ASTM D751 (Standard Specification for Geomembranes) or ISO 14412 (Plastics—Geomembranes for use in civil engineering applications), as these certifications make certain the product has gone through rigorous trying out for impermeability, tensile strength, and chemical resistance. Skipping these tests can lead to highly-priced failures— for example, a mine in North America confronted a $2 million cleanup in 2022 after the usage of a low-grade Geomembrane that degraded inside 5 years, inflicting lead-contaminated tailings to seep into a neighborhood river.

2. Strict Installation Quality Control: Avoid Leaks Before They Start

Even the nice HDPE Geomembrane will fail if mounted incorrectly. TSFs require particular set up to dispose of gaps, wrinkles, or vulnerable factors that may want to emerge as leak paths. The following framework outlines necessary best manage steps for Geomembrane installation.

2.1 Critical Installation Steps for HDPE Geomembrane

Before laying HDPE Geomembrane, the TSF base have to be level, compacted, and free of particles (rocks, roots, or sharp objects), and a geotextile underlay like minded with HDPE have to be used to add an more layer of safety in opposition to punctures, as uneven or uncompacted soil can reason the geomembrane to stretch or tear over time; HDPE Geomembrane is joined the use of warmth welding (either extrusion or hot-air welding)— the most fundamental step in installation— and each and every weld should be examined the usage of non-destructive methods, which include air stress checking out (applying air strain to weld seams per ASTM D1974 and checking for strain drops, which point out a leak wanting repair) and vacuum container checking out (using a vacuum field for flat seams to realize small holes, a approach 99% wonderful at figuring out micro-leaks that may want to develop over time); furthermore, make sure HDPE Geomembrane panels are aligned with minimal anxiety to keep away from stress on welds, easy out wrinkles earlier than welding (as they create vulnerable spots), and keep away from putting in geomembranes in severe climate (rain, excessive winds), considering moisture can intrude with welding and wind can motive panels to shift. Hiring licensed installers is non-negotiable— appear for groups skilled in HDPE Geomembrane set up and licensed by means of corporations like the International Association of Geosynthetics Installers (IAGI)— a 2023 find out about via the Geosynthetics Institute observed that TSFs with IAGI-certified installers had 70% fewer leak incidents than these with uncertified teams.

3. Align with Global and Local Compliance Standards: Avoid Legal Risks

Mine tailings storage is closely regulated worldwide, and HDPE Geomembrane structures should meet strict standards to comply with environmental laws. Non-compliance can end result in fines, operational shutdowns, or even crook charges. Below are key requirements to reference, alongside with how HDPE Geomembrane helps compliance.

3.1 Key Compliance Frameworks for HDPE Geomembrane Use

Under the United States’ EPA Tailings Rule (2020), TSFs are required to use “impermeable liners” to stop groundwater contamination, and HDPE Geomembrane meets this requirement with a permeability price of much less than 1 x 10^-12 cm/s— a long way beneath the EPA’s most allowable price of 1 x 10^-7 cm/s— whilst mines have to additionally publish documentation proving the geomembrane’s check consequences and set up records; the European Union’s Mining Waste Directive (2006) mandates that TSFs use liners “resistant to the chemical composition of the tailings,” and HDPE Geomembrane’s resistance to heavy metals (e.g., copper, zinc) and acidic fluids (pH 2–12) ensures compliance, with mines additionally required to habits annual liner integrity tests; in China, GB 18599-2020 (Standards for Pollution Control of Mine Tailings Storage Facilities) requires TSFs to use double liners (a major HDPE Geomembrane and a secondary geomembrane or clay liner) for high-risk tailings and mandates the important liner have a thickness of at least 1.5 mm— a requirement without problems met via widespread HDPE products. To remain compliant, preserve certain information of HDPE Geomembrane specifications, set up reports, and weld take a look at results, as many regulators (like the EPA) require these archives to be stored for the lifetime of the TSF.

4. Implement Long-Term Maintenance and Monitoring: Extend Geomembrane Lifespan

HDPE Geomembrane has a layout lifespan of 30–50 years, but this relies upon on ordinary preservation and monitoring. Even small damages (e.g., a puncture from a fallen tree branch) can strengthen into fundamental leaks if left unaddressed. Below is a proactive protection sketch for Geomembrane systems.

4.1 Maintenance and Monitoring Tips for HDPE Geomembrane

Conduct month-to-month walks of the TSF to visually investigate for HDPE Geomembrane damage, searching for tears, punctures, or symptoms of degradation (e.g., discoloration, brittleness) and paying greater interest to areas close to TSF edges (where geomembranes are most probably to shift or rub in opposition to rocks); installation everlasting leak detection structures beneath the HDPE Geomembrane (e.g., electrical conductivity structures or vacuum sensors), as these alert operators to leaks inside hours for speedy repairs— for example, a mine in Australia used an electrical leak detection gadget to become aware of a two mm gap in its HDPE liner, which used to be constant inside 24 hours to stop contamination; when injury is found, restore HDPE Geomembrane the usage of well suited HDPE patches and warmness welding, warding off brief fixes (e.g., tape) that fail below tailings pressure, and retest the location with air strain or vacuum field techniques after repairs to make sure integrity; in harsh climates, take greater steps to guard HDPE Geomembrane— in bloodless regions, dispose of snow masses directly to stop stretching, and in sunny regions, use UV-stabilized HDPE (standard in most products) to face up to solar damage. Neglecting protection is a expensive mistake— a 2021 incident in Brazil noticed a TSF leak 10,000 cubic meters of tailings after a small Geomembrane puncture went disregarded for 6 months, ensuing in over $5 million in cleanup fees and a 3-month mine shutdown.

Conclusion: HDPE Geomembrane— Your Key to Safe, Compliant Tailings Storage

For mine operators, HDPE Geomembrane is greater than a liner—it’s a vital device for protecting the environment, making sure employee safety, and warding off criminal trouble. By prioritizing first-class fabric selection, strict set up control, regulatory compliance, and long-term maintenance, you can maximize the overall performance of your Geomembrane machine and preserve your TSF invulnerable for decades.

Every step—from deciding on the proper HDPE Geomembrane to conducting month-to-month inspections—contributes to a safer, greater compliant operation. Invest in these practices these days to keep away from the high priced penalties of failure.

If you want similarly support, I can create a printable HDPE Geomembrane TSF Checklist that compiles all key quality, installation, compliance, and renovation steps for on-site use— would you like me to draft that?

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province