The Critical Importance of Geomembrane Seaming: Methods and Best Practices for a Perfect Seal

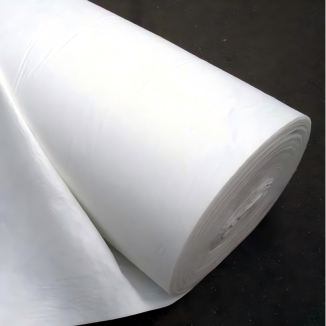

In the world of civil and environmental engineering, the set up of an impermeable geomembrane is a crucial step in growing impenetrable containment barriers. These liners are crucial for defending groundwater from contamination, making sure the structural integrity of reservoirs, and safely containing waste in landfills. However, even the highest-quality HDPE liner is solely as robust as its weakest point: the seams. Geomembrane seaming is the procedure of becoming a member of man or woman panels collectively to shape a continuous, impermeable sheet. The success of the complete containment device hinges on the fantastic and integrity of these seams. A single erroneous seam can lead to catastrophic failure, ensuing in environmental damage, high-priced repairs, and giant liability. This article delves into the necessary significance of appropriate seaming, explores the major techniques used, and outlines the first-rate practices necessary for attaining a perfect, long-lasting seal.

Why Geomembrane Seaming is Non-Negotiable

The principal characteristic of an impermeable geomembrane is to act as a barrier, preventing the passage of beverages or gases. When panels are seamed incorrectly, this barrier is compromised. Even a pinhole-sized leak can lead to a phenomenon known as "advective transport," the place fluids beneath strain can migrate thru the defect, doubtlessly main to soil erosion, pollution, and device failure. For initiatives involving an HDPE liner, which is famend for its chemical resistance and durability, a negative seam creates a inclined factor that undermines the material's inherent strengths. Therefore, geomembrane seaming is now not simply a procedural step; it is the quintessential recreation that ensures the liner performs its supposed feature for decades. It is the distinction between a impervious containment device and an environmental liability.

Primary Methods of Geomembrane Seaming

The approach chosen for geomembrane seaming relies upon on the polymer kind of the liner. For high-density polyethylene (HDPE), the most frequent and strong techniques are thermal fusion techniques. These strategies create a monolithic bond by means of melting the interface of the two panels, successfully making the seam as sturdy as the dad or mum fabric itself.

1. Extrusion Welding

Extrusion welding is a versatile technique regularly used for element work, patches, and in difficult climate conditions. The procedure entails the use of a handheld device that extrudes a molten ribbon of the identical polymer fabric (e.g., HDPE) at once into the seam vicinity between the two overlapping panels. A warm air jet preheats the surfaces of the HDPE liner simply earlier than the molten polymer is applied, making sure a robust molecular bond as the substances cool and fuse together. This technique is particularly wonderful for subject repairs and for seaming in constrained areas the place large tools can't reach. The satisfactory of HDPE geomembrane welding with the aid of extrusion relies upon closely on the ability of the technician to preserve steady temperature, pressure, and journey speed.

2. Dual Hot Wedge (or Hot Air) Welding

Dual warm wedge welding is the most broadly distinctive technique for growing long, straight manufacturing unit and subject seams on an HDPE geomembrane. This computerized procedure makes use of a self-propelled welding desktop that travels alongside the overlap between two panels. The laptop has a heated wedge that passes between the two sheets, melting their surfaces. As the sheets are pressed collectively by means of opposing rollers right away after the wedge, they fuse. There are two variants:

Dual Track Welding: Creates two separate weld seams with an uninterrupted air channel between them. This channel is indispensable for non-destructive air strain testing.

Single Track Welding: Produces a single, wider weld and is usually used for substances like LLDPE or PVC.

This technique is prized for its consistency and the capacity to operate instantaneous fantastic manipulate exams on the seam. Proper execution of twin warm wedge HDPE geomembrane welding effects in a seam with exceptional peel and shear strength.

Best Practices for Achieving a Flawless Seal

Achieving a best seal requires greater than simply the proper equipment; it needs a rigorous adherence to quality practices at some point of the installation process.

1. Subgrade and Panel Preparation

Before any geomembrane seaming begins, the subgrade should be right prepared. It have to be smooth, compacted, and free of sharp rocks, debris, or moisture that ought to puncture the liner or intervene with the seaming process. The HDPE liner panels should be deployed with ample overlap (as distinctive through the design, commonly three to 6 inches) and should be clean, dry, and free from wrinkles, dirt, or moisture at the seam edge. Any infection will stop a desirable bond.

2. Qualified Personnel and Equipment Calibration

HDPE geomembrane welding is a professional trade. Technicians should be significantly trained and licensed on the unique gear and substances they are using. Furthermore, welding tools have to be calibrated daily, and earlier than beginning any new seam, to make sure the temperature, speed, and strain settings are right for the precise thickness and components of the impermeable geomembrane. Ambient climate conditions, such as wind, temperature, and precipitation, ought to be always monitored, as they considerably affect the seaming process.

3. Robust Quality Assurance and Quality Control (QA/QC)

A complete QA/QC software is the spine of profitable geomembrane seaming. This entails three key activities:

Destructive Testing: Sample seams are created in the course of the trial seam procedure at the begin of every day and reduce out for laboratory testing. These samples are examined for peel and shear electricity to confirm that the welding parameters are correct.

Non-Destructive Testing (NDT): This is carried out on one hundred percent of the manufacturing seams. For dual-track welds, the predominant NDT approach is air stress testing, the place the channel between the welds is pressurized with air to take a look at for leaks. Other NDT techniques encompass vacuum container checking out and spark testing.

Construction Quality Assurance (CQA): An impartial third-party inspector ought to be on-site to oversee all preparation, seaming, and trying out activities, making sure compliance with the mission specifications.

Conclusion: The Seal of Success

The set up of an impermeable geomembrane is a tremendous funding in environmental safety and assignment integrity. Compromising on the fantastic of geomembrane seaming jeopardizes that complete investment. By grasp the quintessential significance of the seam, choosing the fabulous HDPE geomembrane welding method, and carefully imposing a way of life of best via quality practices in preparation, personnel training, and testing, assignment proprietors can be assured they have finished a best seal. A well-executed seam ensures that the HDPE liner will characteristic as a single, durable, and impermeable barrier, safeguarding the surroundings and the project's long-term success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province