Choosing the Right Geocell Material for Slope Protection Projects

Slope safety is a cornerstone of civil engineering and environmental initiatives, as it upholds stability, curbs erosion, and safeguards infrastructure. Geocells have emerged as a main answer for slope stabilization, but with a range of substances available, deciding on the fabulous one is essential. This article delves into how to pick out the quality geocell material, their applications, and pinnacle practices for putting in geocell grid for slope safety to help in making knowledgeable task decisions.

What Are Geocells and Their Significance in Slope Protection?

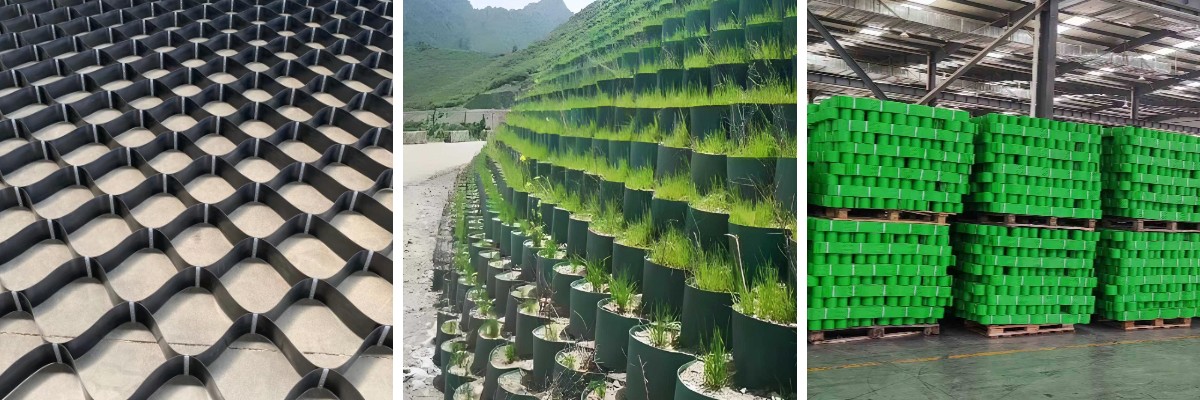

Geocells are 3D honeycomb - like buildings crafted from polymeric materials. They enclose soil, aggregate, or different fill materials, growing a inflexible but bendy matrix. This matrix reinforces slopes, distributes loads, and resists lateral movement, making them noticeably nice for geocell slope stabilization.

In slope protection, geocells beautify shear strength, decrease erosion, and forestall soil displacement. They reduce the danger of landslides, mudslides, and harm precipitated via floor runoff, which is fundamental for tasks in hilly areas, development sites, and coastal regions.

Common Geocell Materials: Characteristics and Applications

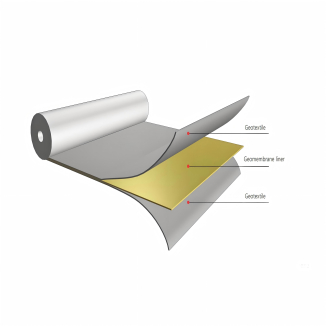

Geocells are specifically made from excessive - density polyethylene (HDPE), polypropylene (PP), and polyester (PET). Each cloth has wonderful facets that go well with precise slope safety needs.

HDPE Geocells: Durable for Heavy - Duty Tasks

HDPE is extensively utilized due to its excessive tensile strength, chemical resistance, and UV stability. It can stand up to severe temperatures, from freezing prerequisites to hot, arid climates, making it best for lengthy - time period geocell slope stabilization. It is resistant to corrosion, rotting, and organic breakdown, making sure sturdiness in harsh environments.

However, HDPE is stiffer than different materials, which limits its flexibility on rather uneven slopes. It performs satisfactory on reasonable to steep slopes (up to 3:1) and in initiatives requiring heavy load capacity, such as dual carriageway embankments and mining sites. When it comes to putting in geocell grid for slope safety with HDPE, its pressure helps preserve the shape beneath pressure.

PP Geocells: Flexible for Complex Terrains

Polypropylene geocells are greater bendy than HDPE, making them best for slopes with irregular shapes or ordinary ground movement. They are lightweight, effortless to transport, and fee - effective, making them famous for small to medium - sized projects. PP is resistant to acids and alkalis, appropriate for industrial or agricultural slope protection.

Their essential downside is decrease UV resistance in contrast to HDPE; besides coatings, they degrade extra shortly in sunlight. They are appropriate for mild to reasonable slopes (2:1 to 4:1) and transient stabilization, such as building embankments. Geocell purposes for PP encompass quick - time period erosion manage in uneven areas.

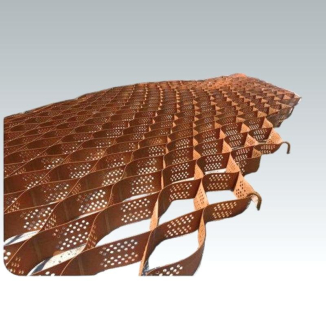

PET Geocells: Strong for High - Stress Zones

Polyester geocells have tremendous tensile power and dimensional stability, even below lengthy - time period stress. They are resistant to abrasion and can take care of heavy loads, making them best for steep slopes (1:1 to 2:1) and areas with excessive site visitors or seismic activity. PET additionally has brilliant UV resistance, making sure sturdiness in sunny locations.

Nevertheless, PET is extra highly-priced than HDPE or PP, which limits its use in finances - restrained projects. It is reserved for crucial functions like dam slopes, coastal protection, and landslide - susceptible areas. In geocell slope stabilization for excessive - stress zones, PET’s energy is unparalleled.

How to Select the Right Geocell Material

The desire of the proper cloth relies upon on venture - unique factors. Evaluating these elements ensures each overall performance and fee - effectiveness:

Slope steepness and terrain

Steeper slopes require substances with excessive tensile power and rigidity. HDPE or PET are appropriate for slopes steeper than 2:1, whilst PP works nicely for gentler ones. For uneven or rocky terrain, bendy PP or PET adapt higher than inflexible HDPE. Installing geocell grid for slope safety on steep slopes needs substances that can stand up to lateral pressure.

Environmental conditions

Consider UV exposure, temperature extremes, and the presence of chemicals. HDPE and PET thrive in sunny, warm areas, whilst PP might also require UV inhibitors. In industrial zones with chemical runoff, HDPE’s resistance is valuable. These elements impact geocell purposes and the durability of the material.

Project lifespan

Temporary initiatives (5–10 years) can use PP to decrease costs, whilst everlasting buildings (20 + years) advantage from HDPE or PET. For coastal or wetland slopes, HDPE’s water resistance is key for lengthy - time period geocell slope stabilization.

Load requirements

Heavy masses from vehicles, equipment, or constructions name for sturdy materials. PET or thick HDPE grant the quintessential support, whilst PP is enough for lighter loads. This is a key consideration in geocell functions involving heavy usage.

Best Practices for Installing Geocell Grid for Slope Protection

Proper set up is quintessential to maximize the effectiveness of geocells. Follow these steps:

Site preparation: Clear away debris, vegetation, and unfastened soil. Compact the floor to create a secure base. Address drainage through putting in pipes or gravel trenches to stop water buildup, which is quintessential for geocell slope stabilization.

Unfolding and anchoring: Expand the geocell panels alongside the slope, aligning them with the contours. Anchor them at the top, bottom, and seams the use of stakes or anchors to forestall shifting, making sure the grid stays in region at some stage in and after filling.

Filling materials: Use soil, aggregate, or vegetation primarily based on the challenge goals. For erosion control, combine soil with grass seeds. For support, use compacted aggregate. The proper fill enhances the effectiveness of geocell applications.

Seaming and overlapping: Overlap the panels through 10–15 cm and tightly closed them with clips or warmth fusion (for HDPE) to structure a continuous barrier, stopping soil leakage that ought to undermine slope stability.

Other Geocell Applications

Beyond slope stabilization, geocells have a extensive vary of uses:

Road construction: They fortify roadbeds to limit agreement and lengthen the lifespan of pavements, which is a key geocell software in infrastructure.

Landscaping: They are used to construct maintaining walls, backyard terraces, or inexperienced roofs, showcasing their versatility.

Coastal protection: They forestall seaside erosion and stabilize dunes, comparable to their function in slope safety however in marine environments.

Mining: They incorporate tailings and stabilize waste piles, making use of their confinement properties.

These geocell purposes spotlight their adaptability throughout quite a number projects.

Maintenance for Long - Term Performance

Regular inspections are integral to hold geocells effective. Check for tears, free anchors, or fill loss. Repair small tears with patches and re - anchor moving panels. For vegetation - included slopes, trim overgrowth to keep away from root damage.

With ideal care, HDPE and PET can remaining 20–30 years, and PP can final 10–15 years, making them fee - high quality for lengthy - time period slope protection.

Final Thoughts

Choosing the proper geocell cloth has a extensive influence on slope stability, durability, and budget. By assessing slope steepness, the environment, and the assignment lifespan, you can choose HDPE, PP, or PET that meet your needs. Proper set up of geocell grid for slope safety and normal preservation are additionally crucial.

Whether for motorway embankments, coastal defense, or landscaping, geocells provide dependable geocell slope stabilization. Their versatility makes them a pinnacle desire for balancing safety, efficiency, and sustainability.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province