Why Choose HDPE Geocell? Key Advantages Over Traditional Geosynthetics

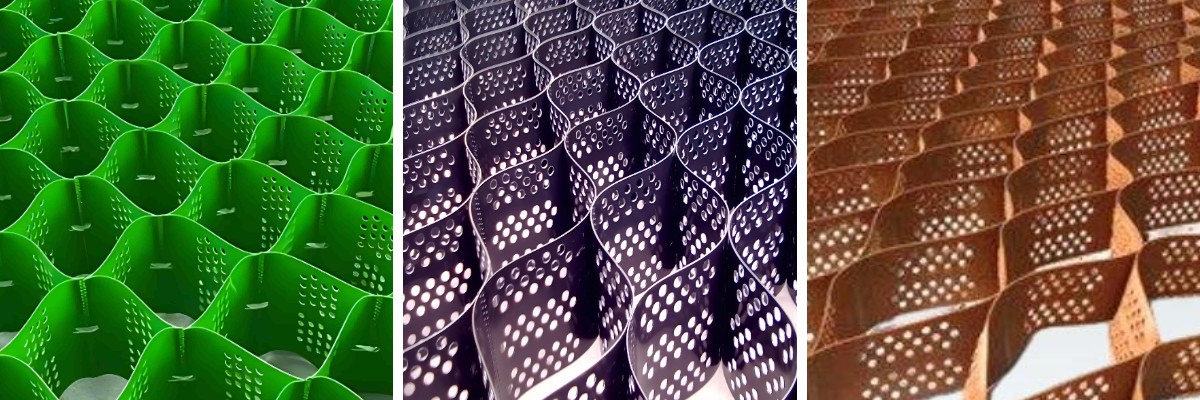

In civil engineering and construction, choosing the proper geosynthetics is indispensable for a project’s durability, efficiency, and cost-effectiveness. Among a number of options, HDPE geocell stands out as an innovative solution, constantly outperforming ordinary geosynthetics like woven geotextiles, rubberized geomembranes, and gravel-reinforced grids in real-world applications. Its special honeycomb structure, blended with high-density polyethylene’s inherent properties, provides advantages that extend from project initiation to long-term maintenance. Let’s delve into the key blessings that make it a preferred choice for engineers and contractors worldwide.

1. Exceptional Strength and Longevity

1.1 Withstands Harsh Environments

Traditional geosynthetics frequently struggle with environmental stressors. Woven geotextiles, for instance, can degrade by up to 30% in tensile strength after simply 5 years of UV exposure, whilst rubber geomembranes may crack in extreme temperature fluctuations. HDPE geocell, by contrast, is a geocell material engineered to thrive in harsh conditions. Its high-density polyethylene composition resists oxidation, making it impervious to most industrial chemicals, saltwater, and acidic soils—a critical characteristic for coastal projects or industrial waste sites.

In a 2022 study by the International Geosynthetics Society, geocell hdpe samples exposed to continuous UV radiation and heavy rainfall retained 95% of their original tensile strength over 10 years, in contrast to a 40% loss in typical polypropylene geotextiles. This resilience makes it ideal for projects in barren region climates, where UV intensity is extreme, or in mining areas with excessive soil acidity.

1.2 Maintains Performance Over Time

The structural integrity of HDPE geocell is further enhanced by its honeycomb design. Unlike non-woven geotextiles that fray at the edges or tear beneath repeated load cycles, the interconnected cells of geocell hdpe distribute stress uniformly, preventing localized failure. This is specifically crucial in slope protection geocell systems, where soil motion and hydrostatic strain can pressure substances over time.

A case study of a motorway slope in Colorado, USA, validated this advantage: a slope protection geocell installation remained secure after 15 years of freeze-thaw cycles and annual rainfall exceeding 120cm, whilst an adjoining slope strengthened with common rock mesh required alternative after eight years due to rusting and soil erosion. With a common lifespan of 20–50 years (depending on infill material), HDPE geocell reduces the want for high-priced retrofits, a primary gain for long-term infrastructure projects.

2. Superior Load Distribution for Soil Stability

2.1 Overcomes Traditional Limitations

Traditional geosynthetics regularly fail to tackle soil instability beneath dynamic loads. Geotextiles, for example, act specially as separators however provide minimal reinforcement, main to uneven compaction in avenue bases. Gravel grids, on the different hand, can shift below heavy traffic, developing voids that reason pavement rutting.

HDPE geocell solves this with its 3D honeycomb structure. When stuffed with mixture or soil, the cells lock the infill cloth in place, growing a inflexible but bendy matrix that distributes vertical masses horizontally. Laboratory tests exhibit that a 10cm-tall geocell hdpe layer can minimize soil contraction by up to 60% in contrast to a geotextile-only base, even underneath repeated truck masses of forty tons. This load-spreading functionality is game-changing for susceptible soil conditions, such as clayey or sandy substrates frequent in coastal plains.

2.2 Ideal for Road Construction

In avenue construction, this interprets to smoother, longer-lasting pavements. A motorway undertaking in Texas changed normal geotextile underlayment with HDPE geocell in 2018; after 5 years, the area with geocell hdpe showed 70% much less rutting than adjoining lanes the use of traditional materials.

2.3 Ideal for Slope Protection

For slope protection geocell applications, the advantages are equally striking. On a 35-degree slope in the Swiss Alps, a slope protection geocell machine crammed with nearby gravel avoided soil creep at some point of seasonal thawing, whilst a close by slope bolstered with concrete blocks skilled 15cm of motion in the identical period. The cell structure’s capacity to “grip” soil particles minimizes erosion, even in areas with heavy rainfall or snowmelt runoff.

3. Efficient Installation Saves Time and Labor

3.1 Simplifies the Process

Traditional geosynthetic set up is frequently labor-intensive. Geomembranes require warmness welding or adhesive sealing to forestall leaks, a manner that can add 2–3 days to a 10,000㎡ project. Geotextiles, meanwhile, want overlapping seams (typically 30cm) and anchoring with metal stakes each and every two meters, growing fabric waste and labor hours.

HDPE geocell streamlines set up with its lightweight, modular design. Rolls of geocell material weigh 15–20kg per 100㎡, in contrast to 40–50kg for equal geotextile rolls, making transportation and on-site coping with easier—especially in faraway areas with restricted heavy equipment access. The interlocking edges of geocell hdpe panels join in seconds the usage of plastic clips, casting off the want for specialised tools.

In a 2023 task in rural Kenya, a crew of three employees set up 800㎡ of HDPE geocell in a single day for a neighborhood road, a assignment that would have required 5 people and two days with ordinary geotextiles.

3.2 Boosts Project Progress

The pace of set up without delay affects challenge timelines. For emergency repairs, such as a washed-out slope on a essential highway, slope protection geocell can be deployed and practical inside 24 hours. In contrast, typical rock revetment would take 3–5 days to source, transport, and place.

A 2021 evaluation via the American Association of State Highway and Transportation Officials observed that tasks the use of HDPE geocell decreased building time by means of an common of 22% in contrast to these the usage of typical geosynthetics. This acceleration now not solely cuts labor fees however additionally minimizes visitors disruptions—critical for city roadworks the place every day of closure can value neighborhood organizations lots in misplaced revenue.

4. Versatile Across Multiple Applications

4.1 Beyond Single-Function Materials

Traditional geosynthetics are regularly confined to unique roles: geomembranes for waterproofing, geotextiles for filtration, and so on. This specialization forces contractors to supply a couple of merchandise for a single project. A standard landfill, for example, would possibly require geomembranes for lining, geotextiles for drainage, and gravel grids for reinforcement—each with separate set up processes.

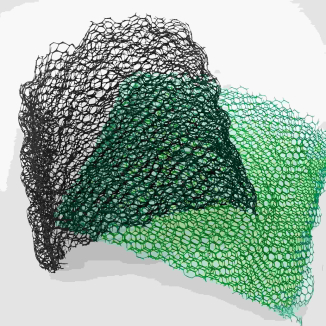

HDPE geocell eliminates this complexity with the aid of serving a couple of functions. In landfill construction, it acts as a reinforcement layer for the cap, a drainage channel for leachate, and a separator between soil and waste. For slope protection geocell projects, it combines erosion manage with vegetation support: the cells can be stuffed with topsoil and grass seeds, growing a dwelling slope that stabilizes soil whilst mixing with the environment.

In coastal engineering, geocell hdpe is used each as a breakwater reinforcement (to take in wave energy) and as a sand retention gadget (to stop seashore erosion), changing the want for separate rock armor and sand fences.

4.2 Customizable for Specific Needs

This geocell material is rather adaptable to assignment requirements. Manufacturers provide cellphone sizes ranging from 10cm (for pedestrian paths) to 50cm (for heavy-duty industrial yards) and heights from 5cm (for shallow soil reinforcement) to 30cm (for steep slope stabilization). Thicker panels (20–30cm) are perfect for preserving partitions up to 5 meters high, whilst thinner 5cm panels work properly for residential driveway bases.

A tremendous instance is the 2020 renovation of a ancient park in London, the place HDPE geocell with 15cm cells used to be used to support pathways barring disrupting tree roots—a flexibility typical concrete grids couldn’t match. The customizable graph ensures a ideal suit for initiatives of any scale, from outdoor drainage structures to 100km railway embankments.

5. Cost-Effective in the Long Run

5.1 Balances Initial and Long-Term Costs

While HDPE geocell has a greater upfront value than fundamental geotextiles (approximately 15–20% greater per rectangular meter), its long-term financial savings are substantial. Traditional substances regularly require usual maintenance: geotextiles may additionally want alternative each 7–10 years, and gravel grids can shift, requiring regrading each 3–5 years.

A 10-year lifecycle evaluation of a 5km rural street determined that the usage of geocell hdpe resulted in complete fees (initial + maintenance) 35% decrease than the usage of geotextiles. The savings stemmed from decreased pavement repairs (due to higher load distribution) and fewer replacements (due to longer lifespan). For industrial amenities with heavy automobile traffic, the financial savings are even greater: a warehouse with a geocell hdpe-reinforced yard said 80% fewer pothole repairs over 15 years in contrast to a neighboring facility with a normal asphalt base.

5.2 Saves in Specific Projects

For slope protection geocell applications, the price blessings are specially pronounced. Traditional rock slope stabilization requires transporting heavy boulders, which can fee 50–80 per ton in faraway areas. HDPE geocell, by means of contrast, makes use of nearby infill cloth (soil, gravel), decreasing transportation charges with the aid of 60–70%.

In a 2022 motorway slope restore venture in the Himalayas, the usage of geocell hdpe with neighborhood stone infill reduce fabric fees via $200,000 in contrast to importing rock armor. The light-weight nature of geocell hdpe additionally reduces gasoline consumption for transportation: a single truck can elevate adequate cloth to cowl 10,000㎡, whereas rock armor would require 5–6 vehicles for the equal area.

Conclusion

HDPE geocell represents a paradigm shift in geosynthetic technology, presenting most useful strength, versatility, and cost-effectiveness in contrast to standard options. Its potential to stand up to harsh environments, distribute hundreds efficiently, simplify installation, and adapt to various purposes makes it an precious asset for present day building projects. Whether used as slope protection geocell, street reinforcement, or landfill liner, this geocell material offers long-term overall performance that regular geosynthetics without a doubt can’t match. For engineers and contractors in search of reliability, efficiency, and value, geocell hdpe is the clear choice.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province