Geomembrane Pond Liners for Fish Farms: Durability & Cost Benefits

The international aquaculture enterprise is projected to develop at a CAGR of 4.5% via 2030, pushed with the aid of rising demand for sustainable seafood. For fish farm operators, deciding on the proper pond liner gadget is indispensable to making sure long-term operational success. Geomembrane pond liners, mainly HDPE geomembrane solutions, have emerged as the gold wellknown due to their unmatched sturdiness and fee efficiency. This article explores why these liners outperform ordinary substances like concrete and clay, and how they supply measurable ROI for present day aquaculture projects.

The Evolution of Fish Farm Pond Liners

Historically, fish farms relied on concrete ponds or compacted clay liners for water containment. While these strategies had been at the beginning cost-effective, they introduced vast limitations:

Concrete: Prone to cracking underneath thermal stress and chemical corrosion from fish waste.

Clay: Requires meticulous web site instruction and is inclined to erosion from water movement.

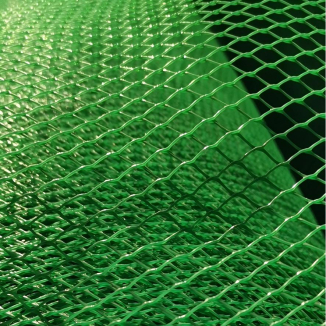

The introduction of impermeable geomembrane structures revolutionized the industry. These artificial liners, manufactured from high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC), provide most useful impermeability and flexibility. Among them, HDPE geomembrane has end up the most extensively adopted due to its brilliant resistance to punctures, UV degradation, and chemical exposure.

Why HDPE Geomembrane Dominates Aquaculture Applications

1. Unmatched Durability

HDPE geomembrane liners are engineered to stand up to harsh aquaculture environments. Key attributes include:

Chemical Resistance: Resists acids, salts, and natural compounds located in fish waste and feed.

UV Stabilization: Carbon black components make certain 50+ years of out of doors publicity besides degradation.

Mechanical Strength: With tensile strengths exceeding 28 MPa and elongation quotes up to 700%, these liners undergo substrate motion and fish activity.

A case find out about from Thailand’s greatest tilapia farm verified zero liner disasters over seven years the use of 1.5mm HDPE geomembrane, no matter every day water stage fluctuations and aggressive fish species.

2. Superior Impermeability

The main characteristic of any pond liner is stopping water seepage. Impermeable geomembrane structures attain this through:

Low Hydraulic Conductivity: HDPE’s molecular shape restricts water migration to ≤1×10⁻¹² cm/s.

Seam Integrity: Factory-fabricated panels or heat-welded area seams put off leakage factors frequent in concrete joints.

In Australia, a shrimp farm decreased water substitute charges with the aid of 65% after switching to HDPE liners, keeping optimum salinity degrees with minimal top-up requirements.

3. Cost Efficiency Across Lifecycle

While preliminary charges for geomembrane pond liners may additionally exceed clay or concrete alternatives, long-term financial savings are substantial:

Installation Speed: A 1-hectare pond can be lined in 3–5 days vs. 4–6 weeks for concrete.

Maintenance: No want for crack repairs or resurfacing, lowering annual OPEX by way of up to 80%.

Water Conservation: Impermeable liners reduce water loss from 30% (clay) to <2%, integral in arid regions.

A Shandong-based carp farm suggested a 3-year payback duration on their HDPE liner investment, with ongoing financial savings of $12,000 yearly from decreased water and power costs.

Key Features to Evaluate When Selecting Geomembrane Liners

1. Material Composition

Virgin HDPE: Offers the absolute best purity and overall performance consistency, perfect for high-stress environments.

Recycled Content: While cost-effective, may additionally compromise UV resistance and elongation properties.

Leading producers like BPM Geosynthetics use one hundred percent virgin HDPE with 2.5–3.0% carbon black content material to make sure compliance with ASTM GRI-GM13 standards.

2. Thickness and Width Options

Thickness: Ranges from 0.2mm to 3.0mm, with 0.75mm–1.5mm being most frequent for fish ponds.

Width: Panels up to 8m broad reduce area seams, decreasing set up time and doable leak points.

For steep-sloped ponds, textured HDPE geomembrane affords better friction angles to stop slippage, as proven in a Peruvian trout farm’s 45° embankment design.

3. Customization Capabilities

Modern suppliers offer:

Color Options: Black for UV protection, white for reflective cooling, or blue for aesthetic appeal.

Custom Dimensions: Rolls up to 200m lengthy to accommodate irregular pond shapes.

A Vietnamese catfish farm optimized their liner sketch by means of incorporating 2m-wide panels with bolstered edges, decreasing waste by way of 18% at some point of installation.

Installation Best Practices for Maximum Performance

1. Site Preparation

Subgrade Smoothing: Remove rocks, roots, and particles to forestall punctures. A 10cm sand layer is frequently recommended.

Slope Stability: Ensure slopes ≤3:1 (horizontal:vertical) for easy liners; textured variations can deal with steeper grades.

2. Seaming Techniques

Heat Welding: Preferred for HDPE, developing monolithic seams more suitable than the base material.

Dual-Track Welding: Provides redundancy, with air channel checks to confirm seam integrity.

3. Anchoring Systems

Perimeter Trenches: Bury liner edges 0.5m deep with backfill compaction.

Ballast Weights: Use concrete blocks or geotextile baggage for floating liners in deep-water applications.

Environmental and Regulatory Compliance

Modern geomembrane pond liners are designed with sustainability in mind:

Non-Toxicity: HDPE is inert to aquatic life, with no leaching of detrimental substances.

Recyclability: At end-of-life, liners can be repurposed into drainage boards or geomats.

Facilities need to comply with regional rules such as the EU’s REACH or US EPA’s NPDES lets in when choosing liner substances and set up methods.

Conclusion: The Future of Aquaculture Containment

As the enterprise shifts towards intensive recirculating structures and offshore farming, the demand for durable, in your price range containment options will solely grow. HDPE geomembrane pond liners characterize the pinnacle of this evolution, providing unmatched overall performance in even the most difficult environments. By investing in nice substances and expert installation, fish farm operators can tightly closed many years of dependable operation whilst minimizing environmental impact.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province