What is a Composite Geomembrane? A Comprehensive Guide

Introduction: The Unsung Hero of Modern Engineering

Beneath our landfills, at the decrease back of our dams, and within the structures that form our trendy world lies a critical, yet often invisible, component: the composite geomembrane. This engineered cloth is a cornerstone of geotechnical and environmental engineering, imparting a robust, dependable barrier against fluids and contaminants. But what exactly is it, and why has it emerge as the fabric of desire for some of the most demanding containment initiatives on the planet?

In this comprehensive guide, we will demystify the composite geomembrane. We will smash down its composition, discover how it works, delve into its a number types and applications, and define the great advantages it offers over single-layer alternatives. Whether you are a assignment engineer, an environmental manager, or truly curious about the materials that guard our infrastructure, this article will supply you with a deep appreciation of this essential geosynthetic product.

Defining the Composite Geomembrane: More Than the Sum of Its Parts

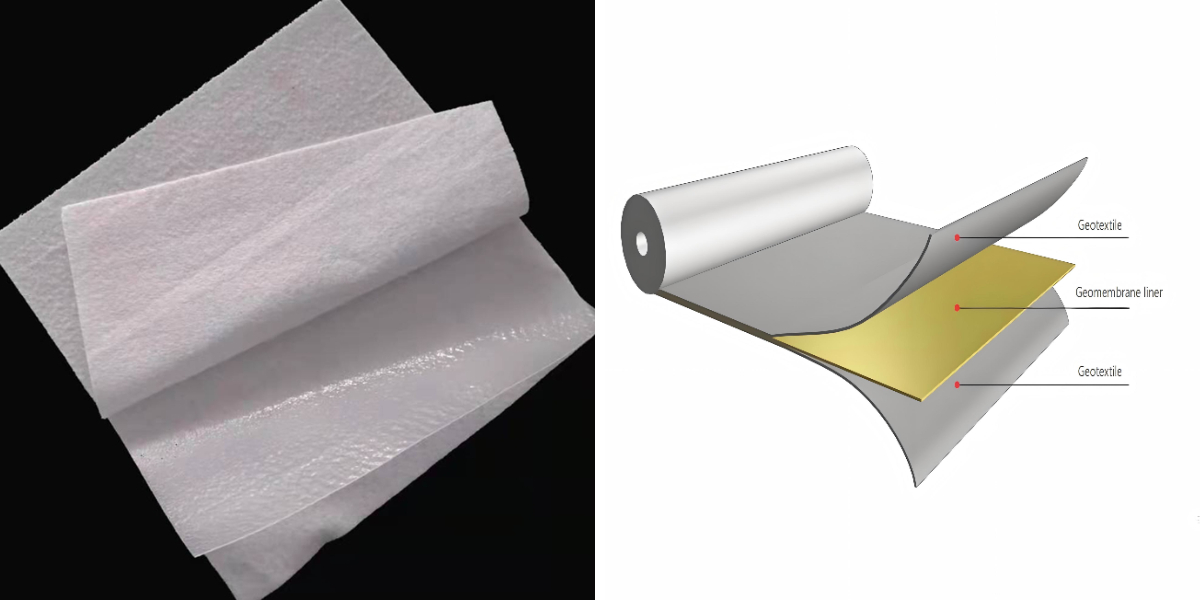

At its core, a composite geomembrane is a manufactured multi-layer material. It is strategically engineered via combining a geomembrane—an in reality impermeable geotextile membrane—with one or greater geotextile layers. The result is a high-performance product that leverages the strengths of every person factor to create a solution choicest to any single layer used alone.

Think of it like a high-tech sandwich. The geomembrane acts as the central, impermeable barrier—the "meat" of the sandwich that blocks the passage of beverages and gases. The geotextile layers are the "bread," presenting crucial protection, filtration, and drainage capabilities. This synergy is the key to its success. The geotextile elements protect the refined geomembrane from puncture and abrasion from the surrounding soil or aggregate, while additionally presenting stronger friction to prevent slippage on slopes. The geomembrane core, regularly a sturdy HDPE composite geomembrane or different polymer, guarantees the primary containment function. This combination creates a extraordinarily effective impermeable geotextile system that is every hard and resilient.

The Anatomy of a Composite Geomembrane: A Closer Look at the Layers

To truly appreciate its functionality, let's dissect the everyday two-ply shape of a standard composite geomembrane.

1. The Impermeable Geomembrane Core

This is the heart of the product, the layer guilty for growing a hydraulic barrier. Its primary job is to be impervious to liquids, such as water, chemical leachates, and gases. The most common materials used for this core include:

High-Density Polyethylene (HDPE): Known for its excellent chemical resistance, excessive tensile strength, and durability. An HDPE composite geomembrane is often the go-to choice for harsh environments like landfills and mining operations.

Linear Low-Density Polyethylene (LLDPE): Offers more flexibility than HDPE and can accommodate greater differential settlement, making it gorgeous for projects with uneven subgrades.

Polyvinyl Chloride (PVC): Highly flexible and handy to seam, high-quality for applications involving complex shapes.

Reinforced Polypropylene (RPP): Provides a stability of puncture resistance and flexibility.

This core layer is what transforms a effortless drainage geotextile into a true impermeable geotextile membrane.

2. The Geotextile Component

Bonded to one or both facets of the geomembrane core is a geotextile. Geotextiles are permeable fabrics, commonly made from polypropylene or polyester, and they serve several critical defensive and sensible roles:

Puncture and Abrasion Protection: The geotextile acts as a cushion, absorbing stresses from sharp rocks, coarse aggregates, or uneven subsoil that would otherwise puncture the geomembrane core.

Drainage and Transmissivity: It provides a aircraft for the lateral go with the flow of liquids or gases, relieving hydraulic pressure that should assemble up against the barrier. This is a key feature that a standalone geomembrane lacks.

Enhanced Friction and Stability: The textured floor of the geotextile exceedingly increases the interface friction angle between the liner and adjoining soils or geosynthetics, dramatically enhancing slope stability.

Filtration: The geotextile prevents great soil particles from migrating into and clogging the drainage layer or damaging the geomembrane.

The aggregate of these two layers creates a single, built-in impermeable geotextile solution that is a long way more high quality and dependable than deploying the layers separately on-site.

How Does a Composite Geomembrane Work? The Science of Synergy

The working principle of a composite geomembrane is elegant in its simplicity: every layer performs its specialized function while concurrently supporting the other. The system's performance is a direct give up end result of this synergistic relationship.

Consider a landfill base liner. The composite geomembrane is installed over a prepared subgrade. The geotextile facet going thru the soil provides immediate protection in the direction of installation and operation. It also permits any minor seepage or fuel to pass through and be channeled away, stopping stress buildup. The geomembrane core acts as an impenetrable wall, containing the leachate within the landfill cell. If the geomembrane core had been a standalone HDPE composite geomembrane without the geotextile, it would be inclined to puncture from the subgrade and ought to experience slippage on slopes.

Furthermore, the geotextile layer facilitates nice control. Its fibrous nature makes it less difficult to perform non-destructive seam testing, making sure the integrity of the established liner system. This built-in approach ensures that the entire impermeable geotextile membrane laptop features as a single, high-performance unit, guaranteeing long-term environmental protection.

Common Types and Configurations

While the classic "geomembrane + geotextile" is the most common, composite geomembranes come in various configurations to meet particular task needs:

Geosynthetic Clay Liners (GCLs): This is a special type of composite the vicinity a layer of bentonite clay (which swells when moist to become impermeable) is sandwiched between two geotextiles. One geotextile is often woven, and the different non-woven, each so often needled together to contain the clay. It's a well-known choice to compacted clay liners.

Drainage Composites: These consist of a geomet (a plastic drainage core) bonded to a geotextile filter on one or both sides. While not always providing a geomembrane, they are a key part of many composite barrier systems.

Multiple Geotextile Layers: Some composites feature a geomembrane core with a heavyweight, non-woven geotextile on one aspect for safety and a lighter geotextile on the other for filtration.

The choice of sort relies upon entirely on the required performance characteristics, such as the required stage of impermeability, the chemical nature of the contained fluid, and the mechanical stresses expected.

Key Applications: Where Are Composite Geomembranes Used?

The versatility of composite geomembranes makes them imperative throughout a wide vary of industries. Their foremost function is always to supply a secure, reliable, and long-lasting barrier.

Landfills (Solid and Hazardous Waste): This is one of the most crucial applications. Composite liners are used in base liners and last caps to prevent leachate from contaminating groundwater and to comprise landfill gas. The robustness of an HDPE composite geomembrane is specially valued here.

Mining and Heap Leach Pads: In the mining industry, these liners include pregnant leach solutions, tailings, and other procedure fluids, defending the surrounding surroundings from highly acidic or alkaline contaminants.

Water and Fluid Containment: They are used to line potable water reservoirs, irrigation canals, firewater ponds, and aquaculture ponds to stop seepage and preserve precious water resources. In these applications, the impermeable geotextile membrane ensures no water is lost to the ground.

Secondary Containment: Around gas storage tanks, chemical processing plants, and different industrial facilities, composite geomembranes act as a secondary barrier to seize spills and prevent them from accomplishing the soil and groundwater.

Tunnels and Civil Infrastructure: They are used as waterproofing liners at the back of segmental linings in tunnels and in other infrastructure projects to forestall water ingress, which can compromise structural integrity.

The Unbeatable Advantages: Why Choose a Composite?

The selection to use a composite geomembrane over a standalone geomembrane or different lining methods is pushed by a compelling set of advantages:

Superior Puncture Resistance: This is the most sizable benefit. The geotextile layer distributes factor hundreds and protects the geomembrane core from sharp objects, drastically lowering the danger of failure.

Enhanced Slope Stability: The excessive friction coefficient of the geotextile-soil interface provides increased resistance to sliding, making composites perfect for steeply sloped containment facilities.

Reduced Interface Friction: Ironically, whilst the geotextile increases friction with soil, it can minimize stress on the geomembrane itself by way of permitting a degree of unbiased movement, accommodating settlement.

All-in-One Installation: The factory-controlled lamination of the layers ensures steady excellent and simplifies installation. It eliminates the need to source, handle, and area separate geomembrane and geotextile layers on-site, saving time and labor costs.

Increased Lifespan and Reliability: By mitigating the principal threats of puncture and abrasion, the composite machine ensures the long-term integrity of the impermeable barrier, leading to a extra dependable and long lasting installation. This makes a well-installed HDPE composite geomembrane system a long-term asset.

Installation and Performance Considerations

The overall performance of any impermeable geotextile machine is solely as good as its installation. Key steps include:

Subgrade Preparation: The basis need to be smooth, compacted, and free of sharp objects or debris.

Panel Placement and Seaming: Panels are rolled out and seamed collectively using techniques like fusion welding (for HDPE/LLDPE) or chemical welding (for PVC). The geotextile layers make positive seaming strategies easier and extra verifiable.

Quality Assurance: Every seam should be tested, normally with non-destructive air pressure or vacuum tests, to make sure a continuous, impermeable barrier.

Conclusion: The Definitive Solution for Modern Containment

A composite geomembrane is some distance extra than just a piece of plastic sheeting. It is a sophisticated, engineered system that represents the pinnacle of containment technology. By intelligently combining the imperviousness of a geomembrane with the shielding and mechanical strengths of a geotextile, it gives you a level of performance, safety, and longevity that single-layer selections can't match.

From safeguarding our water supply to isolating hazardous waste, the feature of the composite geomembrane is vital. Its synergy of materials—creating a genuine impermeable geotextile membrane—makes it the definitive choice for engineers and project managers who can not come up with the money for to compromise on quality and environmental protection. When your project wants a barrier that is as difficult as it is impermeable, a composite geomembrane is the proven, high-performance answer.

Contact Us:

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province