Storing Geotextile Cloth Properly: Protecting Against UV & Physical Damage

Geotextile cloth, moreover stated as geotech fabric, is an essential fabric in geotechnical engineering, substantially used for geotextile soil stabilization, drainage enhancement, erosion control, and as a defending layer for geomembranes. Its general overall performance besides extend influences the sturdiness and protection of engineering projects. However, incorrect storage formerly than set up can lead to UV degradation, bodily damage, and reduced fabric strength, compromising mission fantastic and developing costs. To maximize the fee of geotextile material and make positive its most ideal performance, best storage practices are crucial. This article necessary factors smart storage methods from four core aspects, supporting you effectively defend geotextile resources toward UV radiation and bodily damage.

1. Pre-Storage Preparation: Laying the Foundation for Safe Storage

Adequate pre-storage education is the first step to safeguarding geotextile cloth. This stage consists of inspecting incoming materials, sorting through way of type and usage, and making geared up splendid packaging to prevent preliminary damage. Neglecting pre-storage steps can lead to hidden defects that have an impact on the material’s basic overall performance for the period of later use, in most cases in necessary features like geotextile soil stabilization.

1.1 Inspection of Incoming Geotextile Cloth

Upon receiving geotextile fabric shipments, conduct a thorough inspection to verify fabric quality. Check the product labels for specs such as fabric form (woven, non-woven, needle-punched), weight per unit area, tensile strength, and intended utility (e.g., geotextile soil stabilization, drainage). Examine the flooring of the geotech fabric for symptoms and signs and symptoms of transportation damage, such as tears, punctures, or contamination via capacity of dirt, oil, or chemicals. If any defects are found, report them straight away and contact the issuer for replacement or compensation. Additionally, make sure that the packaging is intact—damaged packaging can expose the fabric to UV radiation and moisture in the route of storage.

1.2 Sorting and Labeling

Sort the geotextile material with the resource of type, specification, and project utilization to preserve away from confusion and harm during storage and retrieval. For example, separate woven geotextiles used for geotextile soil stabilization from non-woven ones used for drainage. Attach clear, weather-resistant labels to each package, indicating key data such as cloth type, specification, quantity, storage date, and supposed project. This sorting and labeling system no longer totally helps fast get entry to on the other hand moreover prevents improper use of materials, making positive that the applicable geotextile material is chosen for each and every application.

1.3 Reinforcing Packaging

Most geotextile cloth is shipped in plastic wrapping or woven baggage to shield toward moisture and dust. Before storage, make stronger the packaging if it is damaged or insufficient. For long-term storage, wrap the geotech fabric with an greater layer of UV-resistant plastic film to enhance security in the direction of sunlight. Ensure that the packaging is sealed tightly to quit the entry of moisture, dust, or pests. For big rolls of geotextile cloth, use bushes pallets to increase the rolls off the ground, heading off direct contact with damp surfaces that can cause mildew or mildew growth.

2. Optimizing Storage Environment: Shielding Against UV and Moisture

The storage environment is a necessary factor affecting the lifespan of geotextile cloth. UV radiation from daylight hours is one of the essential explanations of material degradation, as it breaks down the polymer fibers in geotextiles, reducing their tensile electrical energy and durability. Moisture, extreme temperatures, and chemical publicity can moreover damage the material. Therefore, optimizing the storage environment to restriction these risks is integral for defending geotextile cloth.

2.1 Choosing a UV-Protected Storage Space

Store geotextile cloth in a covered, enclosed residence such as a warehouse or storage shed to hold away from direct sunlight. If backyard storage is unavoidable (e.g., due to place constraints), use a short secure haven with UV-resistant covers (e.g., tarpaulins dealt with with UV inhibitors) to shield the material from sunlight. Ensure that the refuge is well-ventilated to stop warmness buildup, which can velocity up material degradation. Never hold geotech fabric in open areas besides UV protection, as prolonged publicity to daylight hours can reduce its service existence through the use of up to 50% interior a few months.

2.2 Controlling Temperature and Humidity

Maintain a consistent temperature and humidity stage in the storage space. The ideal storage temperature for geotextile material degrees from 5°C to 30°C. Avoid storing the fabric in areas with extreme temperatures, such as shut to heaters, furnaces, or in direct sunlight, as immoderate temperatures can soften the polymer fibers and cause the material to stick together. Humidity want to be saved under 60% to stop moisture absorption, which can lead to mildew increase and fiber degradation. Use dehumidifiers in damp environments and make certain appropriate air go with the flow to flow into air and decrease humidity levels. For geotextile soil stabilization materials, in particular, moisture damage can compromise their structural integrity, making them ineffective in stabilizing soil.

2.3 Avoiding Chemical Contamination

Store geotextile cloth away from chemical resources such as fertilizers, pesticides, solvents, and petroleum products. These chemical compounds can react with the polymer fibers in geotextiles, inflicting discoloration, embrittlement, or complete degradation. If chemical materials want to be saved in the equal warehouse, place them in a separate, sealed neighborhood with ideal containment to end leaks. Ensure that the storage residence is free from fumes or vapors that can penetrate the packaging and damage the geotech fabric. Additionally, preserve away from storing geotextile fabric shut to sharp objects or heavy gear that can puncture the packaging or the material itself.

3. Physical Protection: Preventing Damage During Storage and Handling

Physical damage, such as tears, punctures, and creases, is a widely wide-spread bother at some factor of geotextile material storage. Improper stacking, handling, and contact with sharp objects can compromise the material’s structural integrity, making it unsuitable for use in engineering projects. Implementing first-rate bodily security measures is indispensable to make positive that the geotextile cloth stays intact until installation.

3.1 Proper Stacking Techniques

Stack geotextile cloth rolls horizontally on trees pallets to preserve them off the ground and stop moisture absorption. Ensure that the pallets are sturdy and diploma to preserve away from tilting or collapsing. For woven geotextile rolls used for geotextile soil stabilization, stack them no larger than 3-4 layers immoderate to maintain away from excessive stress on the bottom rolls, which can motive deformation or fiber damage. For non-woven geotextiles, which are increased delicate, restriction the stacking height to 2-3 layers. Avoid stacking heavy objects on pinnacle of the geotextile rolls, as this can crush the material and restriction its tensile strength. Additionally, go away adequate residence between stacks for air circulation and reachable access.

3.2 Safe Handling Practices

Use relevant dealing with equipment, such as forklifts with soft-faced forks or cranes with slings, to pass geotextile cloth rolls. Avoid the utilization of sharp tools or hooks that can puncture the packaging or the material. When lifting the rolls, make sure that the equipment is real placed to distribute the weight evenly, stopping the rolls from slipping or tilting. During transportation interior the storage facility, bypass the rolls slowly and cautiously to maintain away from collisions with walls, shelves, or distinct objects. Train on-site personnel on impervious coping with practices to limit the hazard of accidental damage to the geotech fabric.

3.3 Protecting Against Pests and Rodents

Pests and rodents can harm geotextile cloth with the useful resource of chewing by using the packaging and the material itself. To quit this, keep the storage location convenient and free from ingredients debris, which can entice pests. Use pest manipulate measures such as traps, baits, or pesticides (ensuring they are invulnerable for use spherical geotextile materials) to get rid of pests. Seal any gaps or cracks in the warehouse walls, floors, or doorways to end rodents from entering. Regularly seem to be at the storage neighborhood for signs of pest infestation, such as chunk marks, droppings, or nesting materials, and take instant action if infestation is detected.

4. Inventory Management and Regular Inspection: Ensuring Long-Term Material Quality

Effective inventory administration and regular inspection are quintessential to preserve the fantastic of geotextile material all through long-term storage. By monitoring inventory levels, monitoring material condition, and rotating stock, you can make sure that the oldest supplies are used first and that any damage or degradation is detected early.

4.1 Implementing a First-In-First-Out (FIFO) System

Adopt a FIFO inventory machine to make positive that geotextile cloth is used in the order it is stored. This minimizes the storage time of each and every batch, reducing the hazard of UV degradation and moisture damage. Label each and every stack with the storage date and arrange the inventory so that the oldest rolls are except subject accessible. Regularly exchange the inventory files to track the quantity, specification, and storage length of each and every batch. This gadget is mainly quintessential for geotextile soil stabilization materials, which have strict average overall performance requirements and cannot control to pay for long-term storage degradation.

4.2 Regular Inspection During Storage

Conduct everyday inspections of the saved geotextile fabric to find out any signs and symptoms and signs and symptoms of damage or degradation. Inspect the packaging for tears, holes, or moisture intrusion every and each 2-4 weeks. If the packaging is damaged, repair or alternative it at as soon as to protect the underlying geotech fabric. Unwrap a small aspect of the fabric periodically to take a look at for discoloration, embrittlement, mildew growth, or fiber damage. For geotextile material saved outdoors, make bigger the inspection frequency to weekly, mainly after severe local weather events such as storms or heavy rains. If any degradation is detected, mark the affected rolls and prioritize their use in non-critical functions or discard them if they no longer meet the required specifications.

4.3 Documenting Storage and Inspection Records

Maintain awesome archives of all storage and inspection activities. Document the date of receipt, storage location, inspection results, dealing with activities, and any repairs or replacements made. This documentation offers a clear data of each and every batch of geotextile cloth, helping you tune its circumstance over time and end up conscious of any qualities or issues. It moreover serves as treasured proof for fantastic control, compliance with venture specifications, and assurance claims. Ensure that the information are accurate, up-to-date, and except challenge on hand to relevant personnel.

Conclusion

Proper storage of geotextile fabric is fundamental to shield it closer to UV radiation and bodily damage, making certain that it continues its general overall performance and sturdiness for engineering applications. By following the pre-storage preparation, optimizing the storage environment, imposing bodily security measures, and conducting magnificent inventory administration and regular inspections, you can maximize the value of your geotextile funding and preserve away from expensive undertaking delays or failures. Remember, the key to worthwhile geotextile storage is proactivity—taking steps to stop damage previously than it occurs is a methods greater tremendous than addressing troubles after they arise. Whether you are storing geotextile material for geotextile soil stabilization, erosion control, or drainage projects, these strategies will aid you preserve your supplies in most nice circumstance until installation.

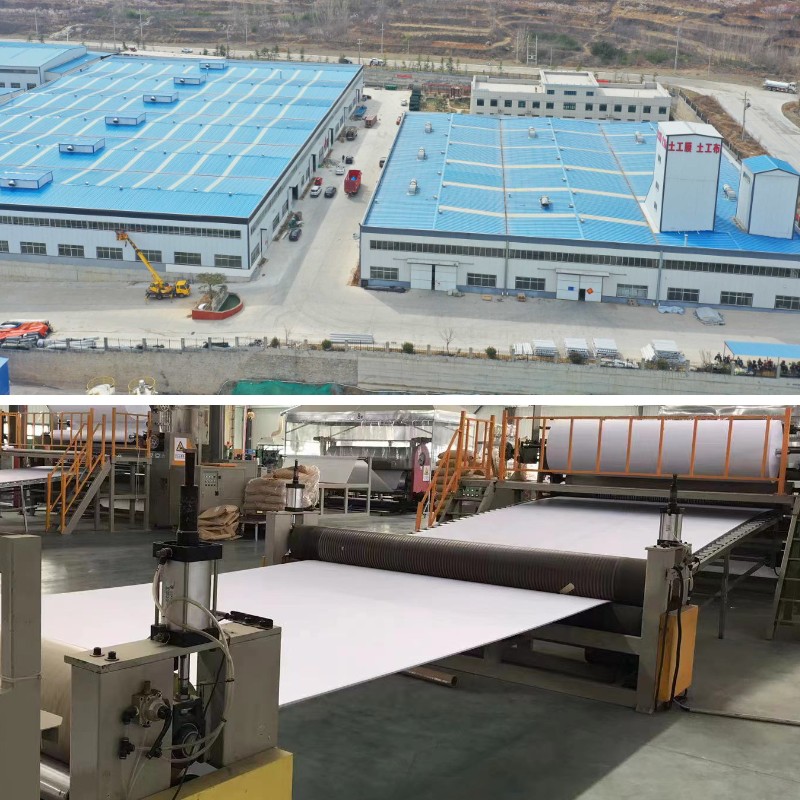

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province