Slope and Embankment Reinforcement with High-Tensile Woven Geotextiles

Introduction: The Critical Need for Modern Stabilization Solutions

The steadiness of slopes and embankments is a necessary situation in civil engineering, infrastructure development, and environmental management. From dual carriageway and railway embankments to reservoir dams and landscaped earthworks, these constructions are eternally challenged through gravity, water infiltration, and seismic activity. Traditional strategies of stabilization, such as costly protecting partitions or deep soil mixing, frequently come with excessive fees and tremendous environmental disruption. In this context, the use of engineered geosynthetics has revolutionized the field. Among these, High-Tensile Woven Geotextiles stand out as a premier answer for Slope and Embankment Reinforcement, presenting unparalleled strength, durability, and diagram flexibility. This article delves into how these superior materials, together with specialised Reinforced Machine Woven Fabric, supply reliable, long-term steadiness and erosion manipulate for vital earth structures.

What are High-Tensile Woven Geotextiles?

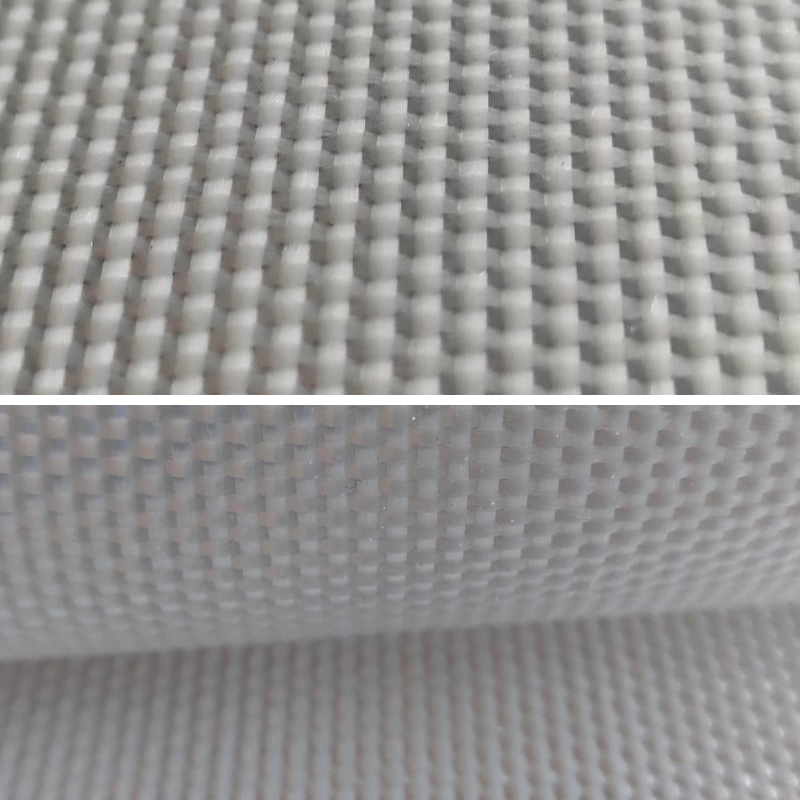

High-tensile woven geotextiles are planar, polymeric fabric manufactured the usage of particular weaving techniques. Unlike their nonwoven counterparts, which are generally used for filtration and separation, woven geotextiles are engineered for their most advantageous mechanical properties. The interlocking of high-tenacity yarns—often polypropylene or polyester—creates a dimensionally secure material with top notch tensile electricity and low elongation.

This precise class of Reinforced Machine Woven Fabric is characterised by using its excessive modulus, that means it can endure massive masses with minimal stretching. This makes it an best cloth for reinforcement functions the place stress switch and soil confinement are paramount. When built-in into soil masses, these fabric act as a tensile element, complementing the soil's herbal compressive energy to create a stronger, composite material. For tasks worrying Slope Stabilization Woven Geotextile solutions, this tensile capability is the key to stopping shear failure and mass movement.

The Engineering Principle: How Reinforcement Works

The essential precept at the back of soil reinforcement is analogous to the characteristic of metal rebar in concrete. Soil is robust in compression however susceptible in tension. By introducing a high-tensile geotextile layer, engineers create a strengthened soil mass that can stand up to tensile forces it in any other case ought to not.

In slope and embankment applications, the geotextile layers are positioned horizontally between compacted soil lifts. As the soil mass tries to pass or slide below gravitational or hydraulic forces, shear stress develops alongside attainable failure planes. The embedded High-Tensile Woven Geotextile mobilizes its tensile power to face up to this motion thru friction at the soil-fabric interface. This interplay correctly "ties back" the unstable soil sector into the steady mass at the back of it, growing the universal thing of safety. This equal reinforcement mechanism is essential when making use of a specialised Erosion Control Woven Geotextile underneath floor safety layers, the place it stabilizes the substrate to stop undercutting and washouts.

Key Advantages Over Traditional Methods

The adoption of high-tensile woven geotextiles for reinforcement presents compelling advantages throughout undertaking lifecycles.

Superior Strength and Performance: These fabric grant enormously excessive tensile electricity from the second of installation, permitting for steeper, extra space-efficient slopes and greater embankments.

Cost-Effectiveness: They extensively decrease the want for steeply-priced imported fill substances or complicated concrete structures. Installation is quicker and requires much less heavy equipment in contrast to common methods.

Design Flexibility: Engineers can tailor the reinforcement by way of specifying the number, spacing, and electricity of geotextile layers to meet genuine assignment demands, whether or not for a fundamental toll road embankment or a landscaped slope. This flexibility is a hallmark of current Reinforced Machine Woven Fabric systems.

Durability and Longevity: Made from inert polymers, extraordinary woven geotextiles are resistant to organic degradation, chemical compounds in the soil, and UV radiation (when buried), making sure diagram overall performance for decades.

Dual Functionality: Many woven geotextiles mix reinforcement with separation, stopping the intermixing of subsoil and fill material, which preserves the structural integrity of the soil layers.

Primary Applications in Slope and Embankment Projects

The versatility of these substances leads to huge use in severa applications.

Reinforced Steep Slopes and Embankments: This is the core application. Woven geotextiles allow the building of stable, vertical, or near-vertical slopes for highways, railways, and constructing sites, maximizing usable land. A Slope Stabilization Woven Geotextile is mainly chosen for its tensile modulus to make certain long-term creep resistance beneath consistent load.

Foundation Support over Soft Soils: Embankments constructed over soft, compressible soils chance differential contract and failure. Layers of reinforcement distribute masses greater evenly, appearing as a mattress to enhance bearing ability and international stability.

Erosion Control and Channel Reinforcement: While frequently related with smooth armoring, a strong Erosion Control Woven Geotextile serves as a imperative underlayer in challenging armor structures (like riprap or concrete blocks). It prevents soil loss via the armor, continues the integrity of the drainage layers, and enhances the standard balance of the channel or shoreline slope.

Landfill Capping and Closure Systems: On the facet slopes of landfill caps, woven geotextiles strengthen the cowl soil, stopping slippage and making sure the integrity of the barrier layers underneath.

Retaining Wall Backfill Reinforcement: They are imperative to Mechanically Stabilized Earth (MSE) walls, the place layers of cloth tie the wall face to the strengthened soil mass at the back of it.

Design and Installation: Critical Considerations for Success

Successful implementation hinges on suited graph and meticulous installation.

Design Parameters: Engineering layout ought to account for soil parameters, slope geometry, exterior masses (traffic, surcharge), and hydraulic conditions. The choice of the fabulous High-Tensile Woven Geotextile is primarily based on required tensile strength, soil-fabric interplay traits (adhesion and friction), and sturdiness criteria.

Site Preparation: The basis should be graded and compacted. Any vegetation or particles that may want to intrude with most desirable soil-fabric contact should be removed.

Fabric Placement and Anchorage: Rolls of Reinforced Machine Woven Fabric are laid perpendicular to the slope face with ample overlap (typically 0.3 to 1.0 meters). The uphill give up ought to be appropriate anchored in a trench to strengthen full tensile resistance. Fabric ought to be laid taut besides wrinkles however now not stretched all through placement.

Fill Placement and Compaction: Selected fill cloth is positioned and unfold in unfastened lifts over the fabric. Compaction is then carried out the usage of gear that will now not injury the geotextile. The method repeats layer by using layer till the graph peak is reached. Care should be taken to make sure the Slope Stabilization Woven Geotextile stays top placed and is now not punctured by using sharp mixture at some stage in compaction.

Surface Protection: On completed slopes, instantaneous vegetative or armor-based safety is necessary to stop floor erosion, which can undermine the bolstered structure. An Erosion Control Woven Geotextile may additionally be used as a transient mulch containment layer or a everlasting phase of the floor armor gadget to guard the underlying reinforcement.

Conclusion: Building a Stable Future with Advanced Geotextiles

High-tensile woven geotextiles have basically modified the method to slope and embankment engineering. By imparting a lightweight, strong, and within your budget ability of soil reinforcement, they allow safer, greater economical, and extra sustainable earth structures. From the foundational assist provided by way of Reinforced Machine Woven Fabric to the centered steadiness of a Slope Stabilization Woven Geotextile and the shielding characteristic of an Erosion Control Woven Geotextile, these substances provide a complete toolkit for modern-day engineers.

For venture owners, civil engineers, and contractors dealing with geotechnical challenges, specifying the right high-tensile woven geotextile is a strategic choice that ensures long-term performance, reduces environmental impact, and optimizes task budgets. As infrastructure needs develop and local weather resilience turns into increasingly more critical, these superior geosynthetic options will proceed to be integral in constructing and defending the foundations of our world.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province