Municipal and Industrial Sludge Dewatering with Geotube Technology

Introduction: The Growing Challenge of Sludge Management

In today’s environmentally aware world, municipalities and industries face mounting stress to manipulate wastewater and procedure sludge effectively and sustainably. The usual strategies of dealing with liquid sludge—such as lagoon storage, mechanical dewatering presses, or off-site hauling—are frequently costly, energy-intensive, and logistically challenging. This is the place modern dewatering applied sciences step in, presenting a robust, cost-effective, and environmentally sound solution. Geotube dewatering technological know-how has emerged as a main approach for remodeling liquid sludge into manageable solids, offering good sized advantages for a broad vary of applications. This article explores how this science works and its pivotal position in cutting-edge sludge management, whilst additionally touching on associated options like stormwater filter bags, sludge filter bags, and erosion manage sediment tubes.

What is Geotube Dewatering Technology?

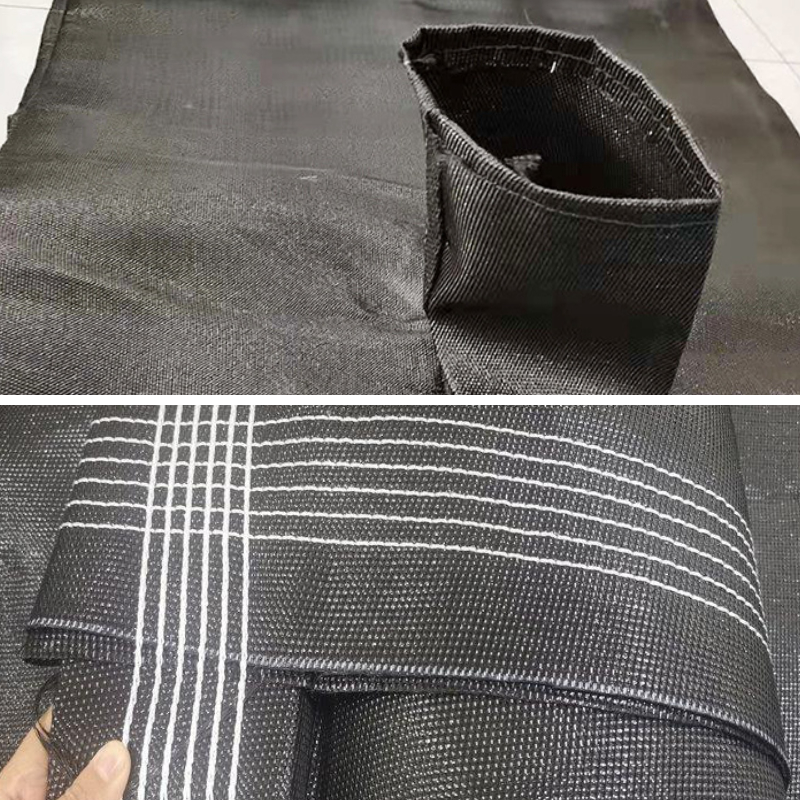

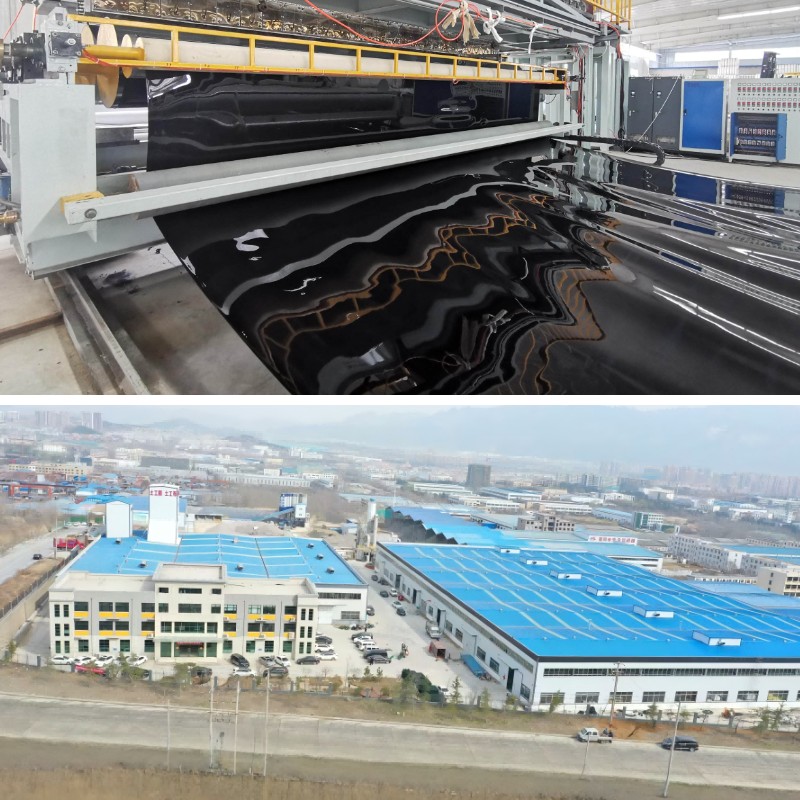

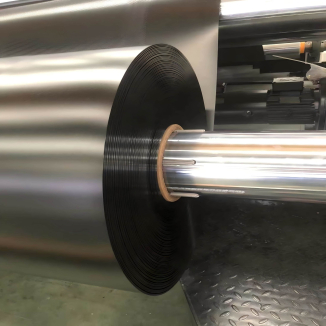

Geotube dewatering technological know-how makes use of high-strength, permeable geotextile containers to dewater slurry-like materials. The technique entails pumping sludge—whether from municipal wastewater cure plants, industrial processes, or dredging operations—into in particular engineered tubes. These tubes are designed to maintain satisfactory solids whilst permitting easy water to filter out via the geotextile pores.

The core precept is easy but especially effective. As the sludge is pumped into the tube, flocculants are frequently delivered to bind fantastic particles together. Water then drains from the tube below gravity, drastically decreasing the sludge volume. The retained solids proceed to consolidate over time, once in a while aided by way of evaporation, ensuing in a stable, dry cloth that is a whole lot simpler and less expensive to handle, transport, or dispose of. This technique is carefully associated to different filtration solutions, such as sludge filter baggage used for smaller-scale or point-source applications, and shares the identical essential filtration mechanics.

Key Benefits for Municipal and Industrial Applications

The adoption of geotube science brings a host of blessings for each public area and personal industrial operators.

Cost Efficiency: It considerably reduces disposal charges through reducing sludge extent via up to 90%. On-site dewatering eliminates the want for continuous, luxurious transportation of liquid waste.

Operational Simplicity: The machine requires minimal infrastructure and power in contrast to complicated mechanical dewatering plants. It is convenient to set up at once at the supply of the sludge.

Versatility and Scalability: The technological know-how can deal with a vast range of sludge types, which include alum, biological, mineral, and contaminated sediments. Units can be sized from small stormwater filter baggage for brief silt manipulate to huge tubes for large-scale dredging projects.

Environmental Compliance and Safety: The dewatering technique is contained, minimizing odor, spill risk, and neighborhood disruption. The filtered effluent water regularly meets requirements for secure discharge. Furthermore, the equal geotextile technological know-how is deployed in erosion manipulate sediment tubes to stop soil loss and shield water first-rate on development sites, showcasing its environmental defensive role.

The Dewatering Process: Step-by-Step

A profitable geotube dewatering mission follows a systematic approach:

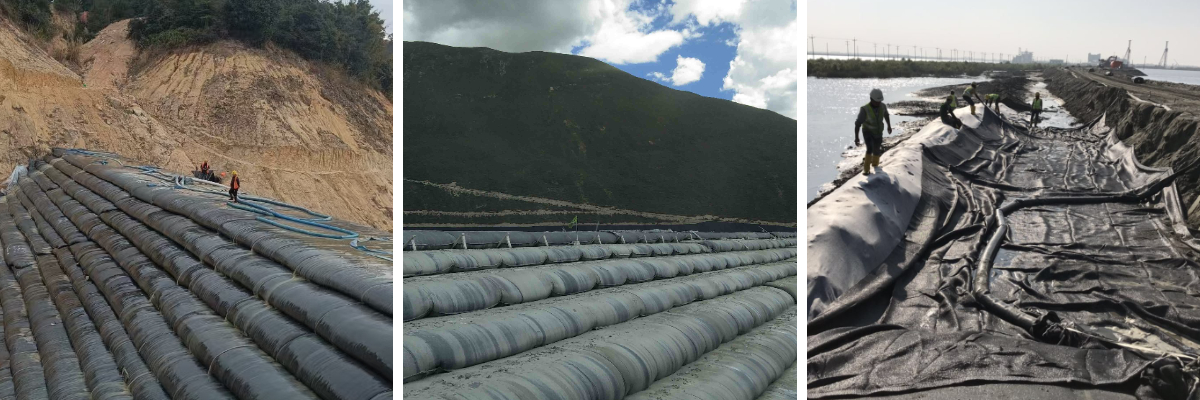

Site Preparation and Tube Deployment: A appropriate region is prepared, frequently with a lining for leachate collection. The empty geotube containers are positioned on this platform.

Conditioning and Pumping: Sludge is blended with polymer flocculants in a mixing unit. This imperative step agglomerates best particles, growing large "flocs" that will be effectively retained through the geotextile.

Filling and Dewatering: The conditioned slurry is pumped into the tubes. Free water starts offevolved to drain at once via the tiny pores in the fabric, comparable to the characteristic of committed sludge filter baggage used in industrial settings.

Consolidation and Curing: After filling, the tubes are left to consolidate. Additional cycles of filling may additionally occur. Over weeks or months, in addition dewatering takes place by drainage and evaporation, leaving in the back of stable cake.

Final Handling: Once wholly dewatered and solidified, the geotextile can be removed, and the dry solids can be land-applied, used as landfill cover, or disposed of in a landfill at a fraction of the authentic moist weight.

Diverse Applications Across Sectors

The flexibility of geotube science makes it worthwhile throughout severa sectors.

Municipal Wastewater Treatment: Plants use it to dewater water therapy residuals, digested biosolids, and lagoon cleanouts. It is additionally instrumental in managing sediments from stormwater ponds, the place stormwater filter baggage are often employed for pretreatment or smaller volumes.

Industrial Processing: Industries such as mining, pulp & paper, meals processing, and energy technology make use of it for tailings, spinoff sludge, and manner water treatment. Here, sludge filter baggage would possibly serve as a supplementary or predominant device for precise waste streams.

Environmental Remediation and Dredging: It is the go-to answer for dewatering contaminated sediments from river, lake, and harbor dredging, safely containing pollutants. This utility is a cornerstone of sustainable sediment management.

Construction and Erosion Control: Beyond dewatering, the science is tailored for perimeter manage in the structure of erosion manipulate sediment tubes. These tubes are positioned alongside seashores or development perimeters to lure sediment from runoff, stopping water air pollution and land loss.

Environmental Impact and Sustainability

Geotube dewatering is inherently a inexperienced technology. By considerably lowering the quantity of waste, it minimizes the footprint and influence of landfills. The on-site technique cuts greenhouse gasoline emissions from transportation. The easy filtrate can be recycled lower back into tactics or safely discharged, conserving water resources. Furthermore, by means of enabling the containment and drying of contaminated materials, it prevents leaching and protects groundwater. The parallel use of erosion manipulate sediment tubes on development web sites exemplifies the proactive use of geotextiles to stop environmental injury earlier than it occurs, aligning flawlessly with sustainable improvement goals.

Conclusion: A Smart Solution for Modern Waste Challenges

Geotube dewatering technological know-how represents a paradigm shift in how municipalities and industries method sludge and sediment management. It combines efficiency, economy, and environmental stewardship in a single, scalable package. From large-scale municipal lagoon cleanouts to centered industrial waste streams managed with sludge filter bags, and from dredging tasks to perimeter safety the use of erosion manage sediment tubes, this geotextile-based answer provides unparalleled versatility.

For task managers, engineers, and environmental specialists searching for a reliable, cost-effective, and sustainable dewatering method, this technological know-how affords a compelling answer. By adopting such progressive solutions, we can meet regulatory demands, manage operational costs, and fulfill our collective accountability to shield the environment.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province