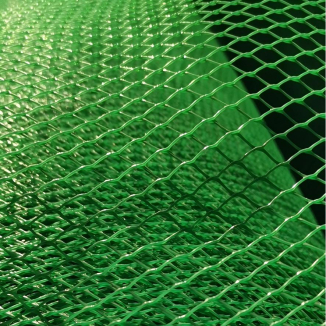

Permeable Filter Fabric Long-Term Durability of Geotextile Cloth: UV Resistance, Tear Strength, and Service Life

In civil engineering, environmental remediation, and landscaping projects, permeable geotextile (also recognised as water permeable filter fabric) performs a vital position as a barrier, separator, and filter. Unlike typical impermeable materials, geotextile filter material balances water permeability with structural stability—making its long-term sturdiness non-negotiable. A low-quality permeable filter material can degrade prematurely, main to assignment failures, high priced repairs, and environmental risks. This article breaks down 5 key elements that decide the provider lifestyles of geotextile cloth, supporting you choose a dependable answer for long-term performance.

1. UV Resistance: Shielding Permeable Geotextile from Sunlight Damage

One of the largest threats to geotextile filter cloth uncovered to outside environments is ultraviolet (UV) radiation. Prolonged daylight publicity breaks down the polymer fibers in permeable geotextile, weakening its structure, decreasing tear strength, and sooner or later inflicting brittleness or disintegration. For tasks like avenue construction, landfill liners, or agricultural drainage systems—where water permeable filter material stays above floor for decades—UV resistance is make-or-break.

High-durability permeable filter material is engineered with UV stabilizers (e.g., carbon black, hindered amine mild stabilizers) throughout manufacturing. These additives soak up or scatter UV rays, stopping fiber degradation. For example, HDPE (high-density polyethylene) primarily based permeable geotextile with 2-3% carbon black content material can continue over 80% of its authentic power after 5 years of outside exposure—compared to much less than 40% for non-stabilized alternatives.

When choosing permeable geotextile, take a look at for third-party certifications (e.g., ASTM D4355) that confirm UV resistance. Avoid low cost selections missing stabilizers, as they may additionally fail inside 1-2 years, compromising your project’s integrity.

2. Tear Strength: Ensuring Geotextile Filter Fabric Withstands Installation & Use

Water permeable filter material faces steady mechanical stress—from set up (e.g., dragging over hard soil, anxiety at some point of laying) to long-term use (e.g., stress from soil, water flow, or heavy loads). Tear strength, which measures a fabric’s potential to face up to ripping, without delay influences how nicely permeable geotextile endures these forces.

Two key metrics outline tear power for geotextile filter fabric:

Trapezoidal tear strength: Tests resistance to tearing alongside a straight facet (critical for set up over sharp rocks).

Puncture resistance: Measures capacity to stand up to factor masses (e.g., tree roots, development debris).

High-performance permeable filter material makes use of woven or non-woven fiber buildings bolstered with high-tenacity polymers (e.g., polyester, polypropylene). Woven geotextile, for instance, has interlocked fibers that distribute stress evenly, imparting tear strengths of 200-500 N (newtons)—ideal for heavy-duty initiatives like holding walls. Non-woven permeable geotextile, whilst greater flexible, nonetheless requires a minimal tear energy of a hundred N for residential landscaping or mild drainage applications.

Always fit the tear power of water permeable filter material to your project’s demands. A material with inadequate energy can also tear at some stage in installation, rendering it vain as a filter or separator.

3. Chemical Resistance: Protecting Permeable Filter Fabric from Harsh Substances

In industrial sites, wastewater remedy plants, or mining operations, geotextile filter cloth comes into contact with chemical substances (e.g., acids, alkalis, oils) that can degrade its fibers. Poor chemical resistance shortens the provider existence of permeable geotextile, inflicting it to lose permeability or structural power over time.

The proper water permeable filter material is tailor-made to the chemical environment:

For acidic soils (e.g., mining web sites with pH < 5), pick out polyester-based permeable geotextile—polyester resists acid corrosion higher than polypropylene.

For alkaline stipulations (e.g., agricultural areas with lime-rich soil, pH > 8), polypropylene permeable filter cloth is extra durable, as it doesn’t react with alkalis.

For oil or hydrocarbon publicity (e.g., gas storage sites), decide for chemically lined geotextile filter cloth (e.g., PVC-coated polyester) to repel oils whilst keeping permeability.

Ignoring chemical resistance can lead to catastrophic failures. For example, a polypropylene permeable geotextile used in an acidic mine drainage machine might also dissolve inside three years, releasing contaminated water into the environment.

4. Soil Compatibility: Preventing Clogging in Water Permeable Filter Fabric

A core feature of permeable geotextile is to filter water whilst stopping soil particles from clogging the fabric’s pores. Clogging—caused via fantastic soil (e.g., silt, clay) getting trapped in the fabric—reduces water flow, undermines drainage, and shortens the provider lifestyles of geotextile filter fabric.

To keep away from clogging, water permeable filter cloth ought to be like minded with the soil type:

For sandy soils (large particles), a non-woven permeable geotextile with large pores (100-200 μm) works best—it lets in water to go with the flow freely whilst blockading sand.

For silty or clayey soils (small particles), a woven permeable filter material with a tight mesh (50-100 μm) is ideal—it traps best particles barring clogging, as the fabric’s shape creates a “filter cake” of soil that prevents similarly particle penetration.

Manufacturers frequently supply “soil-fabric compatibility charts” to suit permeable filter cloth to your soil. For example, ASTM D6241 requirements define take a look at strategies to affirm that a material won’t clog with precise soil types—always reference these earlier than purchasing.

5. Installation & Maintenance: Extending the Service Life of Permeable Geotextile

Even the most long lasting geotextile filter cloth will fail in advance with negative set up or neglect. Proper coping with and preservation are key to maximizing the provider existence of water permeable filter fabric—often extending it from 10 years to 20+ years.

Best Installation Practices:

Prepare the subgrade: Remove sharp rocks, roots, or particles that should puncture permeable geotextile. Smooth the soil to keep away from uneven tension for the duration of laying.

Lay with minimal tension: Overstretching geotextile filter cloth can weaken fibers and limit tear strength. Lay it flat, with 2-3% slack to accommodate soil settlement.

Seam properly: Use warmth welding or needle-punching for seams (not simply stitching)—this ensures seams are as robust as the material itself, stopping water from seeping thru gaps.

Maintenance Tips:

Inspect annually: Check for tears, clogging, or UV damage—repair small tears with geotextile patches, and clear particles from the fabric’s floor to hold permeability.

Avoid heavy loads: Don’t power heavy equipment over uncovered permeable geotextile; use brief covers (e.g., gravel) to distribute weight.

Conclusion: Invest in Durable Permeable Filter Fabric for Long-Term Success

The long-term sturdiness of geotextile filter material relies upon on UV resistance, tear strength, chemical resistance, soil compatibility, and acceptable installation. By prioritizing these factors, you make sure that water permeable filter material or permeable geotextile performs reliably for decades—reducing preservation prices and defending your undertaking from failure.

When buying for permeable filter fabric, appear for merchandise with clear sturdiness specs (e.g., UV take a look at results, tear power ratings) and certifications from legitimate bodies. Remember: a brilliant geotextile filter cloth is now not an expense—it’s an funding in the long-term security and effectivity of your project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province