The Lifespan and Durability of Composite Geomembranes: What to Expect from Your Lining System

When choosing a lining gadget for fundamental containment applications, engineers and challenge managers prioritize long-term overall performance and reliability. Among the a range of options available, the Composite Geo-membrane stands out as a sophisticated, multi-functional barrier. But what precisely must you assume from its carrier life? This article delves into the elements influencing the lifespan and sturdiness of composite geomembranes, supporting you make an knowledgeable choice for your project.

Understanding Composite Geomembranes: A Synergy of Materials

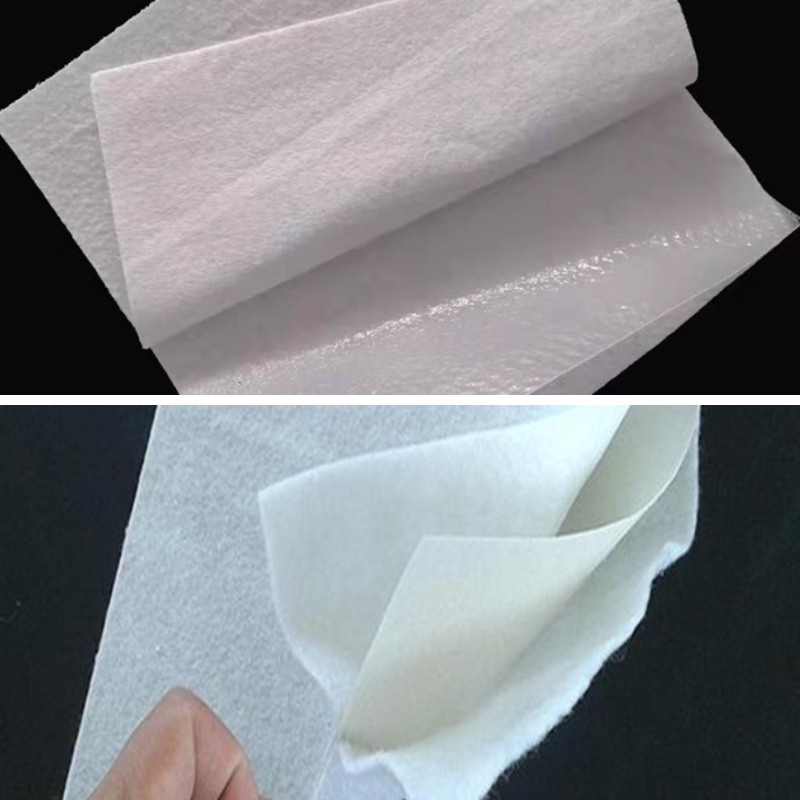

A Composite Geo-membrane is exactly engineered via laminating a geomembrane (often HDPE, LLDPE, or PVC) with a geosynthetic clay liner (GCL) or a geotextile. This aggregate creates a high-performance liner that leverages the complementary strengths of every component. The geomembrane gives awesome impermeability and chemical resistance, whilst the geotextile or GCL provides sturdy mechanical protection, most effective friction characteristics, and superior puncture resistance. This synergy is vital to the prolonged sturdiness of the system, making a Best Composite Geomembrane a pinnacle desire for disturbing purposes the place a single-layer geomembrane would possibly be vulnerable.

Key Factors Determining Lifespan and Durability

The projected provider lifestyles of a composite liner gadget is no longer a single wide variety however a feature of more than one interacting factors. Understanding these is vital for putting sensible expectations.

Material Composition and Manufacturing Quality: The inherent fantastic of the polymer resins and geosynthetics used is the first determinant of longevity. High-quality, virgin-grade polymers with highest quality components (like antioxidants and UV stabilizers) are quintessential for long-term resistance to environmental stressors. The manufacturing system itself—ensuring regular thickness and strong, uniform lamination—directly influences the overall performance of the Composite Geo-membrane.

Environmental and Chemical Exposure: The site-specific surroundings performs a massive role. Key concerns include:

Chemical Compatibility: The liner ought to face up to degradation from the elements it will incorporate (e.g., leachate, industrial fluids) and the surrounding subsoil.

UV Radiation: Unprotected publicity to daylight can degrade polymers. For uncovered applications, composite geomembranes with carbon black or especially formulated UV stabilizers are specified, or they need to be protected promptly.

Temperature Extremes: Both excessive and low temperatures can have an effect on the material's bodily homes and stress-cracking resistance.

Installation Excellence: Even the highest-quality Best Composite Geomembrane can fail in advance if set up incorrectly. Proper subgrade training (smooth, compacted, and free of sharp objects), cautious seaming the usage of licensed techniques (e.g., wedge or extrusion welding), and diligent dealing with to keep away from injury all through placement are non-negotiable for attaining the graph lifespan.

Physical Stresses and Design Considerations: The gadget have to be designed to manage expected stresses, including:

Puncture and Tensile Stress: The geotextile element in a composite liner considerably enhances puncture resistance from the subgrade or overlying materials.

Interface Shear Strength: The textured floor or geotextile layer presents integral friction, stopping slope instability—a essential component for a Landfill Composite Geomembrane in steep aspect slopes.

Long-Term Creep and Stress Cracking: High-quality HDPE-based composites are engineered to limit creep deformation and withstand stress cracking underneath regular load.

Performance in Critical Applications: The Landfill Example

The traumatic surroundings of a contemporary landfill flawlessly illustrates why composite structures are specified. A Landfill Composite Geomembrane, usually a textured HDPE geomembrane needle-punched to a non-woven geotextile or a GCL, is the enterprise general for base liners and closure caps. Here, sturdiness is paramount over decades, even centuries.

In the base liner, the composite gadget have to stand up to the weight of waste, the aggressive chemical cocktail of leachate, and possible settlement. The geotextile aspect faces down, defending the geomembrane from puncture through the underlying drainage layer or subgrade irregularities. In the ultimate cowl system, the composite acts as a barrier to infiltration whilst the geotextile helps gasoline series and gives a secure platform for root limitations and topsoil. The synergy ensures that the Composite Geo-membrane continues its integrity in opposition to biological, chemical, and mechanical challenges a long way longer than both thing may want to alone.

Maximizing the Service Life of Your Lining System

To make certain you recognize the full doable lifespan of your investment, observe these quality practices:

Specify for the Site: Choose a Best Composite Geomembrane whose cloth houses (thickness, polymer type, material weight) are explicitly matched to the project's chemical, physical, and environmental conditions. Don't under-specify.

Prioritize Quality Assurance: Source substances from reliable producers with robust first-class manage and supply third-party certification data. Insist on documentation for each roll.

Invest in Expert Installation: Use certified, skilled installers. A strong Construction Quality Assurance (CQA) application is quintessential to display subgrade preparation, seam integrity, and cloth dealing with in real-time.

Plan for Protection: For uncovered liners, make sure well timed overlaying with a protecting layer or soil. In a Landfill Composite Geomembrane application, make sure the sketch consists of sufficient drainage layers above and under to manipulate hydraulic pressures.

Consider Long-Term Monitoring: Implement a design for periodic inspection and preservation of the liner machine post-installation to pick out and tackle minor troubles earlier than they escalate.

Realistic Lifespan Expectations

Under superior conditions—correct specification, high-quality materials, flawless installation, and a steady chemical environment—a well-engineered HDPE-based Composite Geo-membrane can have a provider lifestyles exceeding a hundred years. More conservative estimates for aggressive environments like landfills regularly cite a format lifestyles of 50 to a hundred years. It’s vital to word that "failure" is regularly described as exceeding a unique leakage rate, no longer a catastrophic breach. The long lasting sketch of a composite device is explicitly meant to prolong the onset of any large permeability make bigger for the longest feasible time.

Conclusion

Choosing a lining machine is a long-term commitment. A Composite Geo-membrane gives a robust, long lasting answer by way of combining impermeability with mechanical resilience. Its lifespan is a direct end result of the great of its components, the rigor of its design, and the care taken at some stage in installation. By perception the elements that have an effect on sturdiness and adhering to great practices in specification and construction, you can confidently assume your composite geomembrane lining machine to grant reliable, not pricey containment for generations. When task protection can't be compromised, opting for a Best Composite Geomembrane tailored to your site’s special challenges is the most strategic funding you can make.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province