Understanding the Different Types of Composite Geotextiles and Their Applications

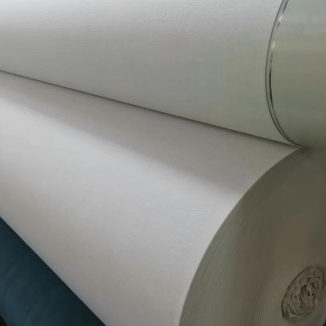

In the world of civil, geotechnical, and environmental engineering, the innovation of geosynthetics has revolutionized how we strategy development and land management. Among these, the Composite Geotextile stands out as a sophisticated, multi-functional material. Unlike single-layer geotextiles, a composite geotextile combines two or greater extraordinary geosynthetic components, such as a geotextile bonded to a geomembrane or every other geotextile layer, to provide most advantageous performance. This integration creates a fabric that leverages the strengths of its character parts—like filtration, separation, reinforcement, and, crucially, containment. When an Impermeable Geotextile layer is included, such as a geomembrane, it creates a barrier machine that is indispensable for initiatives requiring fluid control. Understanding the a range of kinds and their precise features is key to choosing the Best Composite Geomembrane machine for your project's unique challenges.

Core Types and Their Engineering Functions

Composite geotextiles are categorised primarily based on their layered shape and most important function. The most frequent sorts contain combos for drainage, containment, and reinforcement.

Drainage Composites: Often referred to as "geocomposites," these generally pair a geotextile filter with a geonet or geospacer core. The geotextile prevents soil from clogging the drainage core, whilst the core offers a high-flow direction for drinks or gases. This kind is no longer an Impermeable Geotextile; its reason is efficient transmission, making it best for landfill leachate collection, wall drainage, and erosion manipulate in the back of protecting structures.

Barrier/Containment Composites: This is the place the thought of a Composite Geotextile virtually shines as a barrier system. The most usual shape is a geotextile-geonembrane-geotextile (GCL) sandwich, regularly recognised as a geosynthetic clay liner (GCL) when the center layer is bentonite clay. However, for high-performance fluid containment, a strong polymeric geomembrane laminated to one or two layers of geotextile is used. This mixture creates what many engineers are trying to find as the Best Composite Geomembrane. The geotextile layers grant integral puncture protection, tensile strength, and friction towards the subgrade and cowl materials, whilst the geomembrane core offers an extremely good Impermeable Geotextile function, blockading the passage of beverages and vapors.

Reinforcement Composites: These mix high-strength geogrids or meshes with geotextiles. The geogrid presents structural reinforcement for soil stability, whilst the geotextile provides separation and filtration capabilities. This twin motion is best for constructing over smooth soils, developing steep slopes, or reinforcing foundational layers.

Key Applications in Modern Engineering

The versatility of composite geotextiles makes them necessary throughout severa sectors. By supplying more than one options in one product, they limit set up time, enhance reliability, and regularly decrease standard venture costs.

Environmental Containment: This is the premier utility for barrier-type composites. In landfill liner and cap systems, a Composite Geotextile with an impermeable core is critical. It acts as the most important barrier to stop leachate from contaminating groundwater. Similarly, in mining for heap leach pads or tailings dams, specifying the Best Composite Geomembrane is a non-negotiable protection and environmental standard. The geotextile layers guard the touchy geomembrane from sharp rocks and uneven subsidence, making sure the long-term integrity of the Impermeable Geotextile function.

Water Resources Management: From canal and pond liners to reservoir covers, containment composites forestall seepage and preserve water. Drainage composites are equally critical in these settings, used in sub-surface drainage structures to manipulate water stress at the back of dams or inside embankments, stopping structural failure.

Transportation Infrastructure: Under roads, railways, and airfield pavements, composite geotextiles operate a couple of roles. Drainage composites control subsurface water, stopping frost heave and subgrade weakening. Reinforcement composites stabilize vulnerable subsoils, extending the lifespan of the infrastructure. Even a easy Composite Geotextile with a isolating and cushioning layer can lengthen pavement lifestyles by using stopping the intermixing of combination layers.

Erosion Control and Landscaping: On slopes and channels, drainage composites facilitate water egress, decreasing pore stress that leads to landslides. Combined with vegetation, they grant a stable, developing medium for sustainable erosion control. In inexperienced roofs and plaza decks, a layered Composite Geotextile gadget presents drainage, root barrier, and safety features in one installable package.

Selecting the Best Composite Geotextile for Your Project

Choosing the proper Composite Geotextile is no longer a one-size-fits-all process. It requires a cautious evaluation of website online prerequisites and overall performance requirements.

Identify the Primary Function: Is the important want drainage, containment, reinforcement, or a combination? For liquid containment, the integrity of the Impermeable Geotextile core (the geomembrane) is paramount. You have to choose a Best Composite Geomembrane whose core cloth (like HDPE, LLDPE, or PVC) is chemically resistant to the fluids it will encounter.

Analyze Site-Specific Stresses: Consider the subgrade conditions, predicted load, and workable for puncture. A rocky subgrade necessitates a thick, sturdy geotextile cushioning layer in your Composite Geotextile to shield the impermeable barrier. For high-load purposes like landfill liners, the composite ought to have excessive tensile energy and shear resistance.

Consider Hydraulic Properties: For drainage composites, the drift ability (transmissivity) have to exceed the project's requirements. For containment, the permeability of the geomembrane core must be efficiently zero. The geotextile filter layer's obvious opening dimension (AOS) have to be chosen to stop soil migration whilst permitting vital fluid passage.

Evaluate Durability and Longevity: The substances ought to face up to UV publicity (if now not blanketed immediately), chemical degradation, and organic assault for the project's plan life. The exceptional of the lamination or bonding in the Composite Geotextile is imperative to make certain the layers feature as a unified gadget over decades.

Installation and Long-Term Performance

Even the Best Composite Geomembrane will fail if hooked up incorrectly. Key concerns encompass acceptable subgrade preparation—it should be smooth, compacted, and free of sharp objects. Panels ought to be seamed effectively in accordance to the manufacturer's specifications, with specific care for the Impermeable Geotextile layer to make sure a continuous, leak-free barrier. Seams are usually thermally welded for geomembranes. During placement, the Composite Geotextile should be laid barring immoderate anxiety or wrinkles. Immediate protecting per layout specs is frequently required to guard the cloth from UV injury and wind uplift.

For long-term performance, the built-in plan of a Composite Geotextile is its biggest asset. The safety layer preserves the core function, whether or not it is drainage or containment. Regular inspection and maintenance, specially for uncovered applications, assist make sure the machine performs as meant for its complete provider life.

Conclusion

Composite Geotextiles characterize a tremendous development in geosynthetic engineering, providing tailored, high-performance options for complicated floor and water challenges. Whether the assignment needs the most excellent containment of the Best Composite Geomembrane or the multi-functional advantages of a mixed drainage and reinforcement system, these substances supply efficiency, reliability, and cost-effectiveness. By appreciation the special types—particularly the integral position of an Impermeable Geotextile layer in barrier systems—engineers and mission managers can make knowledgeable choices that beautify the sustainability, safety, and toughness of their infrastructure and environmental projects. Investing in the proper composite geotextile is an funding in the enduring success of the construct environment.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province