HDPE Geocell for Airport Runways & Taxiways: Load-Bearing Support for Heavy Aircraft

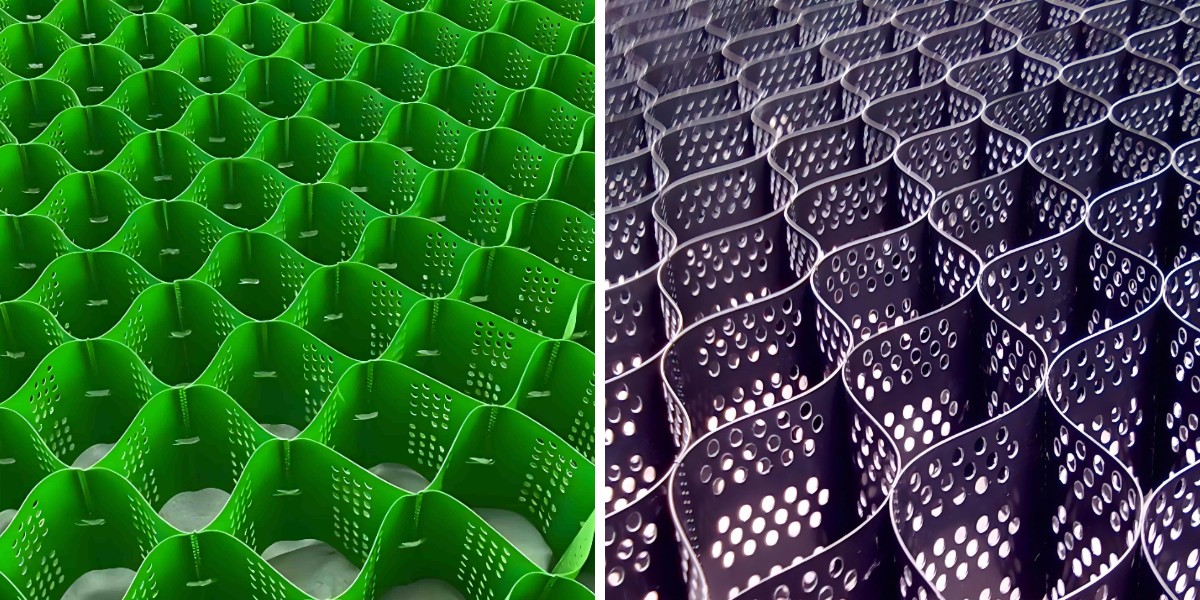

Airport runways and taxiways face remarkable stress from current heavy aircraft—such as Boeing 747s and Airbus A380s—that exert masses of up to 500,000 kg. Traditional pavement constructions frequently suffer from rutting, cracking, and subsidence inside a few years, main to steeply-priced repairs and operational disruptions. HDPE Geocell, a three-d honeycomb shape made of high-density polyethylene, has emerged as a game-changer in airport pavement engineering. By bettering soil stabilization and load distribution, Geocell ensures long-term sturdiness and protection for heavy plane operations. This information explores 4 crucial motives why HDPE Geocell is the pinnacle preference for airport runway and taxiway projects, supporting you apprehend its cost and application.

1. Superior Load-Bearing Capacity: The Core Advantage for Heavy Aircraft

The most important requirement for airport runways and taxiways is to stand up to repeated heavy hundreds barring deformation. HDPE Geocell’s special shape can provide unmatched load-bearing overall performance with the aid of optimizing soil mechanics and load distribution.

1.1 Honeycomb Structure Enhances Soil Stabilization

HDPE Geocell’s third-dimensional honeycomb cells confine and interlock with the infill fabric (such as gravel, sand, or concrete), reworking unfastened soil into a inflexible composite structure. When a heavy plane lands, the load is evenly allotted throughout the whole Geocell-reinforced layer, alternatively than concentrating on small areas. This reduces the most strain on the subgrade by using 30-50% in contrast to common pavement. For example, in a check carried out on a taxiway strengthened with 100mm-thick HDPE Geocell, the pavement withstood 10,000 cycles of 400,000 kg hundreds with solely 2mm of rutting—well under the enterprise restrict of 5mm. This stabilization impact is specially crucial for airports constructed on smooth or unstable subgrades, the place ordinary strategies would require immoderate soil replacement.

1.2 Rigorous Load-Bearing Testing and Standards

Qualified HDPE Geocell for airport tasks have to meet strict enterprise requirements to make certain reliability. The key check is the static load-bearing test, the place a 1m×1m Geocell pattern (infilled with general gravel) is subjected to gradual strain till deformation reaches 10%. Premium HDPE Geocell must stand up to a minimal of five hundred kPa (equivalent to the load of a thoroughly loaded Airbus A380) barring failure. Additionally, the dynamic load check simulates 100,000 touchdown cycles to affirm fatigue resistance—Geocell-reinforced pavements continue 85% of their initial load-bearing potential after these cycles, in contrast to 60% for unreinforced pavements. Reputable producers grant take a look at reviews compliant with ASTM D6393 (Geocell standard) and FAA AC 150/5370-10 (airport pavement guidelines), making sure the product meets aviation protection requirements.

2. Exceptional Durability: Withstand Harsh Airport Environments

Airport pavements function in harsh conditions—repeated heavy crush rolling, excessive temperature fluctuations, chemical exposure, and UV radiation. HDPE Geocell’s fabric and shape are engineered to withstand these factors, making sure a provider lifestyles of 20-30 years.

2.1 Resistance to Fatigue and Abrasion

Heavy plane tires exert now not solely vertical hundreds however additionally horizontal shear forces throughout takeoff and landing, inflicting fatigue and abrasion to pavement layers. HDPE Geocell’s high-density polyethylene fabric has a tensile electricity of ≥20 MPa and an elongation at smash of ≥300%, permitting it to take in shear forces except tearing. The honeycomb shape additionally prevents the infill fabric from shifting, lowering abrasion between particles. In a area find out about at a regional airport, a Geocell-reinforced taxiway confirmed 70% much less abrasion than an adjoining unreinforced area after five years of operation. This sturdiness minimizes the want for widely wide-spread patching, retaining airport operations uninterrupted.

2.2 Tolerance to Extreme Temperatures and Weather

Airports in bloodless areas face freeze-thaw cycles that purpose pavement cracking, whilst these in warm climates go through from thermal expansion. HDPE Geocell keeps its performance throughout a broad temperature vary (-40℃ to 80℃). The material’s low thermal conductivity reduces warmness switch to the subgrade, stopping ice formation in winter. In summer, its flexibility incorporates thermal enlargement except buckling. For example, at an airport in northern Canada, a HDPE Geocell-reinforced runway has operated for 12 years with no freeze-thaw damage, whilst the preceding unreinforced runway required substitute each and every eight years. Additionally, the Geocell’s water-permeable shape drains rainwater quickly, averting waterlogging and subgrade erosion.

2.3 Chemical and UV Resistance

Airport pavements are uncovered to jet fuel, deicing chemical substances (such as ethylene glycol), and engine oil. HDPE Geocell is chemically inert and resistant to these substances—immersion in jet gas for 30 days motives no weight trade or energy loss. To withstand UV radiation, producers add 2-3% carbon black to the HDPE material, stopping brittleness and degradation. A xenon arc weathering check (simulating 20 years of out of doors exposure) indicates that HDPE Geocell retains 90% of its tensile strength, a ways exceeding the enterprise requirement of 75%. This chemical and UV resistance ensures the Geocell continues its overall performance in the lengthy term.

3. Efficient Construction and Site Adaptability

Airport building and renovation require minimal disruption to flight operations. HDPE Geocell’s lightweight, easy-to-install sketch reduces development time and labor costs, making it best for each new tasks and retrofits.

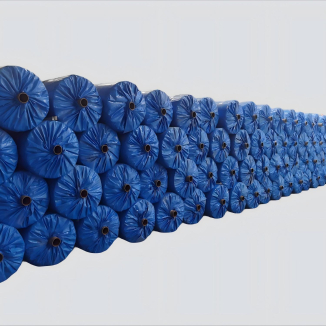

3.1 Quick Installation and Minimal Equipment

HDPE Geocell is furnished in light-weight rolls (10-15 kg per roll) that can be transported and unrolled manually or with small equipment. Installation entails three easy steps: getting ready the subgrade, unrolling and increasing the Geocell (it expands to 10-20 instances its rolled size), and infilling with gravel or concrete. A group of four employees can deploy 500㎡ of Geocell per day—3 instances quicker than ordinary soil stabilization strategies like cement mixing. For example, the retrofit of a 2,000㎡ taxiway at a medium-sized airport took solely five days with HDPE Geocell, in contrast to 15 days with standard methods. This rapid set up minimizes runway closure time, a vital gain for busy airports.

3.2 Adaptability to Complex Site Conditions

Airport websites regularly have uneven terrain, gentle subgrades, or present underground utilities. HDPE Geocell’s flexibility permits it to conform to irregular surfaces barring cracking. For gentle subgrades, the Geocell distributes masses to minimize settlement—no want for costly soil replacement. In areas with underground pipes or cables, the Geocell can be reduce and adjusted to suit round obstacles, heading off expensive utility relocation. During the development of a new runway extension at a coastal airport, HDPE Geocell was once used to stabilize sandy subgrades, removing the want for importing fill material. This adaptability reduces development complexity and fabric costs.

4. Long-Term Cost Efficiency: Reduce Lifecycle Costs

While HDPE Geocell has a greater preliminary value than ordinary materials, its long-term sturdiness and low protection necessities end result in huge lifecycle fee savings—critical for airport operators managing tight budgets.

4.1 Lower Initial Construction Costs

HDPE Geocell reduces the want for thick pavement layers and high priced fill materials. Traditional runways require a 300mm-thick asphalt or concrete layer on a 500mm-thick stabilized subgrade. With Geocell reinforcement, the pavement layer can be decreased to 200mm, and the subgrade thickness to 300mm, reducing fabric prices by using 25-30%. For a 1km-long runway (45m wide), this interprets to financial savings of $500,000-$800,000 in preliminary construction. Additionally, the rapid installation reduces labor and tools condo expenses through 40% in contrast to common methods.

4.2 Minimal Maintenance and Long Service Life

HDPE Geocell-reinforced pavements require minimal maintenance—only pursuits cleansing and occasional patching of small cracks. A find out about via the Federal Aviation Administration (FAA) determined that Geocell-reinforced runways have preservation fees 60% decrease than unreinforced ones over 20 years. For example, a massive global airport said spending $15,000 per 12 months on keeping a Geocell-reinforced taxiway, in contrast to $40,000 per yr for an unreinforced taxiway. Additionally, the Geocell’s 20-30 yr carrier existence is 50% longer than usual pavements, decreasing the frequency of high-priced full replacements.

Key Considerations When Choosing HDPE Geocell for Airports

To make certain most useful performance, choose HDPE Geocell that meets these criteria: 1. Material: High-density polyethylene with a density of ≥0.94 g/cm³ and carbon black content material of 2-3% for UV resistance; two Structure: Cell measurement of 200-300mm (ideal for airport loads) and wall thickness of 1.5-2.0mm; three Certifications: Compliance with ASTM D6393 and FAA AC 150/5370-10; four Manufacturer: Reputable provider with case research of airport tasks and comprehensive after-sales support.

Conclusion: HDPE Geocell—The Future of Airport Pavement Support

For airport runways and taxiways assisting heavy aircraft, HDPE Geocell provides unmatched load-bearing capacity, durability, building efficiency, and price savings. Its honeycomb shape transforms vulnerable subgrades into rigid, load-resistant pavements, whilst its chemical and environmental resistance ensures long-term performance. Whether for new development or retrofitting ageing pavements, Geocell is a demonstrated answer that reduces lifecycle expenses and minimizes operational disruptions. By selecting tremendous HDPE Geocell from a legitimate manufacturer, airport operators can make sure safe, dependable pavement overall performance for many years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province