Choosing the Right Geotextile Fabric: Woven vs. Non-Woven for Your Project

Selecting the right geotextile material is a fundamental choice in many construction, civil engineering, and landscaping projects. These permeable artificial textiles play a necessary position in soil stabilization, filtration, drainage, and separation. The two important categories—woven and non-woven geotextile—each possess wonderful houses and are engineered for particular applications. Understanding their variations is key to making sure the longevity, stability, and cost-effectiveness of your project. This information will delve into the characteristics, perfect uses, and decision standards for these crucial materials.

Understanding Geotextile Fabrics: A Foundational Overview

Before evaluating types, it’s crucial to hold close what a geotextile is and its core functions. A geotextile is a artificial material designed to engage with soil and rock. It is permeable, permitting water to bypass via whilst performing one or extra of the following key functions: Separation, stopping the mixing of diverse soil layers; Filtration, permitting water glide whilst stopping soil erosion; Drainage, facilitating the series and transport of fluids; and Reinforcement, including tensile electricity to the soil for stabilization.

The overall performance in these areas hinges on the geotextile’s bodily properties, such as tensile strength, permeability, and puncture resistance, which are at once influenced by way of its manufacturing process.

Woven Geotextile Fabric: Strength and Stability

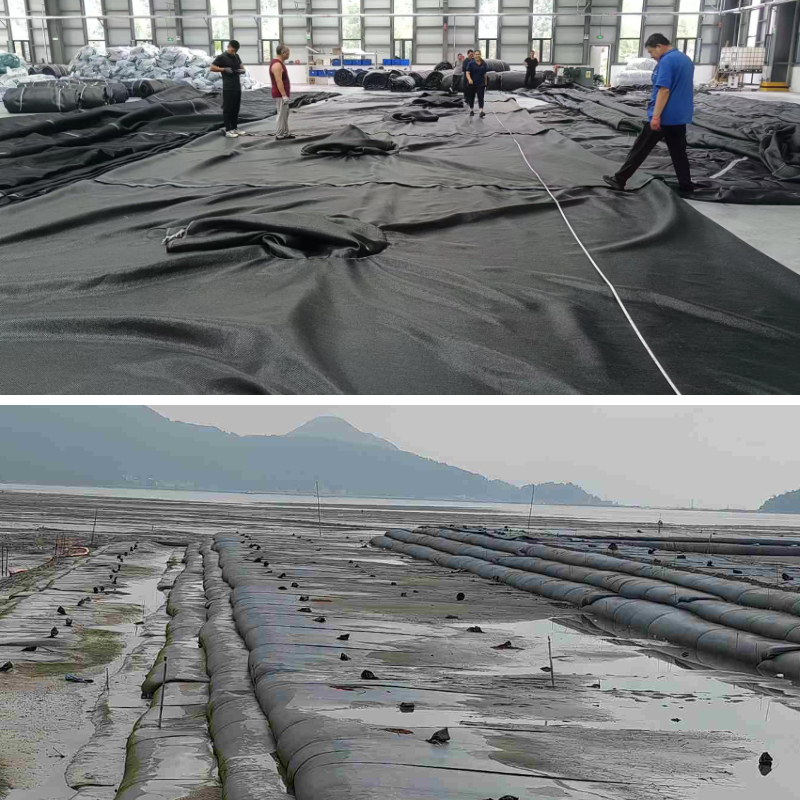

Woven geotextile cloth is manufactured through interlacing artificial yarns, usually polypropylene or polyester, on a loom in an over-and-under pattern. This technique creates a robust, dimensionally steady material with a recognizable grid-like appearance.

Key Characteristics:

●High Tensile Strength: The weaving system consequences in tremendous load-bearing potential and resistance to elongation. This makes woven geotextile cloth an magnificent desire for reinforcement applications.

●Low Elongation: It has minimal stretch beneath load, supplying tremendous structural stability.

●Durable & UV Resistant: Generally provides precise resistance to set up injury and ultraviolet degradation.

●Lower Permeability: While permeable, the tight weave frequently approves for slower water go with the flow in contrast to some non-woven varieties.

Ideal Applications for Woven Geotextile:

The optimal energy of woven geotextile material makes it the desired preference for initiatives requiring soil reinforcement and stabilization. Common makes use of include:

●Road and Railway Base Stabilization: Placed between the subgrade and base mixture to separate layers and grant structural reinforcement, extending pavement life.

●Parking Lots and Access Roads: Reinforces gentle subgrades underneath mixture or asphalt.

●Retaining Walls and Steep Slopes: Provides tensile power to the soil mass, enhancing stability.

●Embankment Support: Used over susceptible soils to distribute hundreds and stop embankment failure.

When your major requirement is long-term tensile power and minimal deformation, a woven geotextile is frequently the best solution.

Non-Woven Geotextile: Filtration and Drainage

Non woven geotextile is produced by using bonding artificial fibers (usually polypropylene or polyester) collectively thru mechanical (needle-punching), thermal, or chemical means. This consequences in a felt-like cloth with a greater random, fuzzy structure.

Key Characteristics:

●High Permeability: The random fiber orientation creates a porous shape that lets in for fast water go with the flow in each planar and transverse directions, excelling at filtration and drainage.

●Puncture and Elongation Resistance: The needle-punched shape gives true resistance to puncture and can conform to irregular surfaces with greater elongation.

●Separation and Cushioning: Effectively prevents intermixing of soil layers whilst additionally supplying defensive cushioning for geomembranes.

●Filtration Efficiency: Excellent for stopping soil piping whilst permitting free water passage.

Ideal Applications for Non-Woven Geotextile:

The filtration and drainage prowess of non woven geotextile makes it essential for many projects. Key purposes include:

●Drainage Systems: Used in the back of conserving walls, in French drains, and round perforated pipes to filter soil particles whilst permitting water to enter the drain.

●Landfill and Pond Liners: Serves as a defensive cushioning layer for impermeable geomembranes, stopping puncture from underlying aggregate.

●Erosion Control: Under rip-rap or revetment systems, it filters soil whilst water passes through, stopping loss of best particles.

●Asphalt Overlay: Often used in pavement rehabilitation as a stress-relieving interlayer to stop reflective cracking.

●Sport Fields and Landscaping: Provides separation and subsurface drainage.

When your project’s success relies upon on high-quality water management, filtration, or protecting cushioning, a non woven geotextile is commonly the encouraged choice.

Key Factors for Choosing Between Woven and Non-Woven Geotextile

Selecting the proper geotextile material requires a cautious evaluation of your project's unique demands. Consider the following factors:

Primary Function: This is the most imperative question. Is the important aim reinforcement (choose woven) or drainage/filtration (choose non-woven)? For separation, each can work, however non-woven is frequently desired for cushioning, whilst woven is chosen for heavy load support.

Soil Conditions: Analyze the soil kind (e.g., clay, silt, sand). Non woven geotextile is regularly specific for finer soils the place filtration is crucial. Woven geotextile cloth is best for stabilizing soft, cohesive soils beneath load.

Load Requirements: For high-traffic areas, everlasting roads, or constructions requiring soil reinforcement, the excessive tensile electricity and low elongation of woven geotextile are paramount. For pedestrian paths or lighter responsibility separation, a non-woven may additionally suffice.

Hydraulic Needs: Evaluate the water float requirements. Projects requiring excessive water transmissivity (like drainage trenches) gain from the permeability of a non woven geotextile.

Survivability: Consider the set up stipulations (sharp aggregate, conceivable for damage). Both kinds have specific puncture and tear strengths, which need to be matched to the website online conditions.

Installation Best Practices for Optimal Performance

Proper set up is as necessary as cloth selection. Key recommendations practice to each woven geotextile material and non woven geotextile:

Site Preparation: Ensure the subgrade is precise graded, compacted, and free of sharp debris, standing water, or vegetation that ought to puncture the fabric.

Roll Placement: Unroll the geotextile easily alongside the organized location besides stretching it. Overlap adjoining rolls as precise (typically 12 to 36 inches), making sure the overlap is in the course of any slope.

Anchoring: Secure the cloth quickly the use of staples or backfill at the edges to stop displacement by means of wind or equipment.

Immediate Backfilling: Place the overlying fill fabric (e.g., aggregate) carefully, losing it from a minimal peak to keep away from damage. Do no longer permit development tools to visitors at once on the uncovered geotextile.

Seaming: For indispensable applications, seams may additionally want to be sewn, thermally bonded, or overlapped in accordance to engineering specifications.

Conclusion: Making an Informed Decision for Project Success

The desire between a woven geotextile material and a non woven geotextile is now not a remember of one being most effective to the other, however instead of deciding on the proper device for the job. By definitely defining your project’s major function—be it reinforcement, filtration, drainage, or separation—you can slim down the right kind of geotextile.

For energy and stabilization beneath heavy, long-term loads, the structural integrity of a woven geotextile is unparalleled. Conversely, for managing water flow, defending liners, and filtering soil, the hydraulic overall performance of a non woven geotextile is commonly the exceptional solution. Always seek advice from the manufacturer’s technical information sheets for unique property values like grasp tensile strength, permittivity, and elongation. When in doubt, consulting with a certified geotechnical engineer or civil engineer can grant project-specific guidance, making sure you pick out the best geotextile material to construct a stable, durable, and profitable mission foundation.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province