How Long Does Geotextile Cloth Last? Factors That Impact Lifespan

Geotextile cloth—also recognized as geotextile or geo fabric—is a versatile cloth used in civil engineering, agriculture, environmental remediation, and landscaping. It filters soil, reinforces structures, controls erosion, and separates layers of materials, making it a staple in infrastructure projects. But one query plagues many users: how lengthy does geotextile fabric simply last? The reply varies widely, ranging from 5 to 25 years, and relies upon on 4 key factors: fabric type, environmental exposure, utility scenario, and installation/maintenance quality. This article breaks down every issue to assist you recognize and lengthen the lifespan of your geo fabric.

1. Material Type: Synthetic vs. Natural Geotextiles

The base cloth of geotextile fabric is the most quintessential component deciding its lifespan. Geotextiles are greatly labeled into artificial and herbal types, every with wonderful sturdiness profiles—and each without delay influence how lengthy the geo material will perform.

1.1 Synthetic Geotextiles: Long-Lasting Durability

Synthetic geotextiles are made from man-made polymers like polypropylene (PP), polyethylene (PE), or polyester (PET). These substances are engineered to face up to degradation, making them the go-to desire for long-term projects. Polypropylene geotextile cloth, for example, is resistant to microorganisms, chemicals, and moisture—all of which smash down different materials. Polyester geotextiles add even extra durability, with excessive tensile power and resistance to UV radiation (when handled with stabilizers). Most artificial geotextiles remaining 15 to 25 years, specially when used in included functions like underground drainage or street bases. For instance, a PP geotextile used to improve a dual carriageway subgrade can keep its performance for over 20 years, outperforming herbal picks by means of a large margin.

1.2 Natural Geotextiles: Biodegradable Short-Term Use

Natural geotextiles are derived from natural substances like coconut fiber (coir), jute, or straw. These geo fabric are eco-friendly and cost-effective, however their biodegradable nature limits their lifespan. Coconut fiber geotextile cloth, for example, breaks down slowly over 5 to 10 years as microorganisms in soil eat the fibers. Jute geotextiles have an even shorter lifespan—3 to 5 years—especially in moist or humid environments. Natural geotextiles are best for brief projects: erosion manipulate on development sites, transient mulch for new plantings, or non permanent soil separation. However, they are now not appropriate for everlasting purposes like landfill liners or everlasting holding walls, the place long-term sturdiness is critical.

2. Environmental Exposure: UV, Temperature, and Moisture

Geotextile fabric hardly ever exists in a managed environment—most are uncovered to sun, severe temperatures, rain, or harsh soil chemicals. These factors speed up put on and tear, and their depth without delay shortens or extends the geo fabric’s lifespan.

2.1 UV Radiation: The Primary Aging Culprit

Sunlight’s ultraviolet (UV) rays are the largest chance to uncovered geotextile. UV radiation breaks down the molecular bonds in polymers, inflicting artificial geotextiles to come to be brittle, fade, and lose tensile strength. A non-UV-stabilized polypropylene geotextile, for example, can degrade in simply two to three years if left totally uncovered to direct sunlight. Even herbal geotextiles suffer—UV rays dry out jute or coir fibers, making them susceptible to tearing. To fight this, producers add UV stabilizers to artificial geotextile cloth, which take in or replicate UV rays. A UV-stabilized PE geotextile used in a landfill cap (partially uncovered to sun) can closing 10 to 15 years, in contrast to simply a few years except stabilization.

2.2 Temperature Fluctuations: Expanding and Contracting Damage

Extreme temperatures—both warm and cold—stress geotextile cloth. In high-heat environments (like barren region regions), artificial geotextiles can soften, dropping their structure and capability to separate soil layers. A PP geotextile uncovered to 60°C (140°F) for extended intervals may additionally begin to deform in 5 to 7 years. In bloodless climates, freezing temperatures make geotextiles brittle: a polyester geotextile in a location with -20°C (-4°F) winters can also crack if subjected to surprising impacts, like heavy gear traffic. Geotextiles buried underground (away from temperature swings) fare better—for example, a buried PE geotextile in a temperate local weather can keep its integrity for over 20 years, as soil acts as an insulator.

2.3 Moisture and Chemical Erosion: Microbial and Acidic Wear

Moisture and soil chemical substances destroy down geotextile fabric over time. Wet environments motivate microbial growth: micro organism and fungi feed on herbal geotextiles (like jute), accelerating decomposition. Even artificial geotextiles are vulnerable—moisture can wash away UV stabilizers, making them greater inclined to solar damage. Soil chemistry provides some other layer: acidic soils (common in industrial sites) corrode polyester geotextiles, whilst alkaline soils (found in some agricultural areas) weaken polypropylene. A geotextile used in a wastewater therapy facility (exposed to acidic effluent) might also final simply eight to 10 years, in contrast to 15+ years in impartial soil. Buried geotextiles keep away from immoderate moisture exposure, however appropriate drainage (to stop waterlogging) is nevertheless key to extending lifespan.

3. Application Scenario and Load Requirements

How you use geotextile cloth—whether for a transient erosion manage mat or a everlasting street reinforcement—directly influences how lengthy it lasts. Different functions expose the geo material to various tiers of stress, load, and wear, which dictate its practical lifespan.

3.1 Permanent vs. Temporary Applications

Permanent purposes demand geotextiles with lengthy lifespans, whilst brief makes use of can remember on shorter-lived options. Permanent tasks encompass avenue and railway subgrades, dam reinforcements, and landfill liners. A polyester geotextile used to give a boost to a dam’s core (buried, included from UV, and beneath steady load) can closing 20 to 25 years. Temporary applications, such as development web site dirt manipulate or brief drainage filters, use geotextiles designed for temporary use. A light-weight PP geotextile used as a dirt cowl on a development website online can also solely want to final 1 to two years, and producers regularly leave out pricey UV stabilizers for these products, retaining prices low.

3.2 Load and Traffic Intensity

The quantity of weight or site visitors a geotextile fabric endures impacts its lifespan. Geotextiles used in high-traffic areas—like toll road shoulders or parking lot bases—must face up to consistent strain from vehicles. A low-tensile-strength geotextile in a busy highway’s subgrade might also tear or stretch past restore in 5 to eight years. In contrast, a high-strength polyester geotextile (designed for heavy loads) can take care of motorway visitors for 15+ years. Even non-traffic hundreds matter: a geotextile beneath a thick layer of soil (for a preserving wall) should help the soil’s weight. If the geo cloth is too weak, it will sag or break, shortening its lifespan from 10 years to simply three or 4.

4. Installation Quality and Maintenance Practices

Even the most long lasting geotextile material will fail upfront if established poorly or unnoticed after installation. Proper set up and ordinary renovation stop avoidable damage, making sure the geo material reaches its most lifespan.

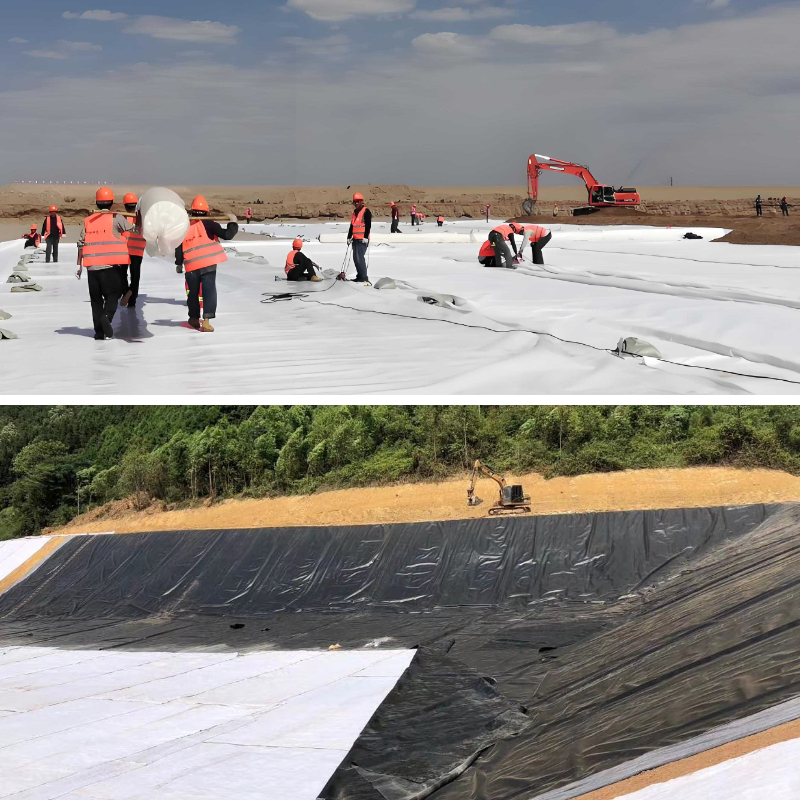

4.1 Proper Installation: Avoiding Initial Damage

Poor set up creates susceptible factors that shorten geotextile life. Common errors include: putting in geotextile over a rough, unlevel base (sharp rocks or particles pierce the fabric); Insufficient overlap of geotextile sheets (gaps allow soil to penetrate,inflicting the material to stretch); and the usage of the incorrect geotextile for the job (e.g., a light-weight herbal geotextile for a everlasting road). A efficiently mounted geotextile cloth—laid over a smooth, compacted base, with 15–30cm overlaps between panels, and secured with anchors—avoids these issues. For example, a PP geotextile hooked up exact for a golf route drainage device can final 12 to 15 years, whilst a poorly established one may additionally fail in three to 5 years.

4.2 Regular Maintenance: Fixing Small Issues Before They Grow

Neglecting protection turns minor harm into important failures. Geotextile material can get punctured by using equipment, torn by means of tree roots, or clogged by way of sediment. A small puncture in a drainage geotextile, for example, will let soil enter the drainage pipe, inflicting clogs and growing strain on the fabric—this can lead to a full tear in 1 to two years if unaddressed. Regular renovation (inspecting the geotextile each and every 6–12 months, clearing debris, and patching small holes with geotextile tape) extends lifespan. A maintained PE geotextile in a agricultural drainage device can remaining 15+ years, whilst an unmaintained one may additionally want substitute in eight years.

Conclusion

The lifespan of geotextile material degrees from 5 to 25 years, however it’s now not a random number—it’s decided with the aid of fabric kind (synthetic lasts longer than natural), environmental publicity (UV, temperature, and moisture speed up aging), software situation (permanent vs. temporary, load intensity), and installation/maintenance quality. By deciding on the proper geo material for your project, defending it from harsh elements, and investing in suited set up and upkeep, you can maximize its lifespan and get the most fee from your investment.

If you’re undecided which geotextile fabric is excellent for your task or want assist estimating its lifespan, I can create a personalized geotextile resolution and lifespan guidelines tailor-made to your software (e.g., avenue construction, erosion control). Would you like this guidelines to information your decision?

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province