How HDPE Geomembrane Protects Agricultural Reservoirs from Leakage (Case Studies Included)

Agricultural reservoirs store water for crops when it’s dry—they’re key for farming. But leakage is a big problem: up to 30% of water can waste away each year. This ruins crops, makes farmers pay more for pumping water, and harms the environment.

Old fixes like clay or concrete liners don’t work long. They crack when soil moves, or break down fast. That’s where hdpe geomembrane (a tough, flexible plastic liner) comes in. It’s also called an hdpe impermeable liner—and it stops leaks way better. Below, we’ll explain how it works, its top perks, real stories, and easy installation tips.

1. Why Leakage Is Bad—and Old Liners Fail

Reservoirs face tricky issues: different soils, changing temps, and heavy machines. Old liners can’t handle these, so they leak.

Problems with Old Liners

Sandy soil leaks fast: Sandy/gravelly soil lets water seep 10x faster than clay. Clay liners need perfect packing—but even small gaps (from roots or settling) let water out.

Concrete cracks: Concrete is stiff. When soil shifts (freezes, rains hard), it cracks. Fixes cost a lot and don’t last—new cracks pop up soon.

Short life: Organic liners (straw/jute) break down in 2–3 years. Asphalt fades and cracks in the sun. You have to replace them often, which messes with farming.

Hdpe geomembrane fixes all this. It’s way more waterproof than clay/concrete, bends with soil movement, and doesn’t break easily. A good geomembrane lasts 30+ years—no more constant repairs.

2. How HDPE Geomembrane Stops Leaks

At its core, an hdpe impermeable liner is a waterproof barrier between water and soil. What makes HDPE so good?

Why It’s Waterproof

HDPE is made of tightly packed plastic molecules. Hardly any water gets through—its “waterproof rate” is super low. To compare:

Clay lets 100,000x more water through.

Concrete is 10x more leaky than clay.

Why It Lasts & Bends

Unlike stiff concrete, hdpe geomembrane bends—it can stretch twice its length without tearing. This works for reservoirs, where soil moves with wet/dry seasons. It also resists:

Sun damage: Additives like carbon black keep it safe from UV rays (even in hot places).

Chemicals: Fertilizers or pesticides from farms don’t break it down.

Rough use: Heavy machines (like irrigation pumps) can drive over it without poking holes—it’s strong.

HDPE is like a “waterproof shield” old liners can’t match.

3. 5 Big Perks of HDPE Geomembrane

Stopping leaks is just the start—HDPE has other big benefits.

(1) Saves More Water

An hdpe impermeable liner keeps 95–98% of water in (vs. leaky clay/unlined reservoirs). For a small 10-acre reservoir, that’s ~12 million gallons saved yearly—enough to water 50+ acres of corn in a drought.

(2) Saves Money Long-Term

HDPE costs more upfront (1.50–3 per square foot vs. 0.80–1.20 for clay). But it lasts 30+ years, while clay needs replacing every 5–10 years. Example:

Clay for a 5-acre reservoir: 20k upfront + 80k in replacements = $100k over 30 years.

Hdpe geomembrane for the same reservoir: 45k upfront + 5k in fixes = 50k total. That’s

40k saved!

(3) Easy to Install

Reservoirs come in all shapes—small ponds, big tanks. Geomembrane sheets can be cut to fit any size, then welded together. A 4–5 person team can line a 1-acre reservoir in 3–5 days. Unlike concrete, you can fill it with water 24 hours later.

(4) Good for the Planet

HDPE helps the environment:

It’s 100% recyclable—many makers use old plastic bottles to make it.

It stops leaks, so farm chemicals (like nitrogen) don’t seep into groundwater.

(5) Hardly Any Maintenance

Once installed, hdpe impermeable liner needs little care. Check it 2–3 times a year for holes (from roots/debris). Fix small tears with an HDPE patch kit. No need to repack it like clay—farmers can focus on crops, not repairs.

4. Real Stories: HDPE in Action

Numbers matter—but real examples show how HDPE helps farms.

Case 1: Small Farm in Kenya

Problem: A 2-acre reservoir for maize lost 25% of water monthly (sandy soil). The farmer spent lots on diesel to refill it, and crops struggled. Clay liners failed in 2 years.

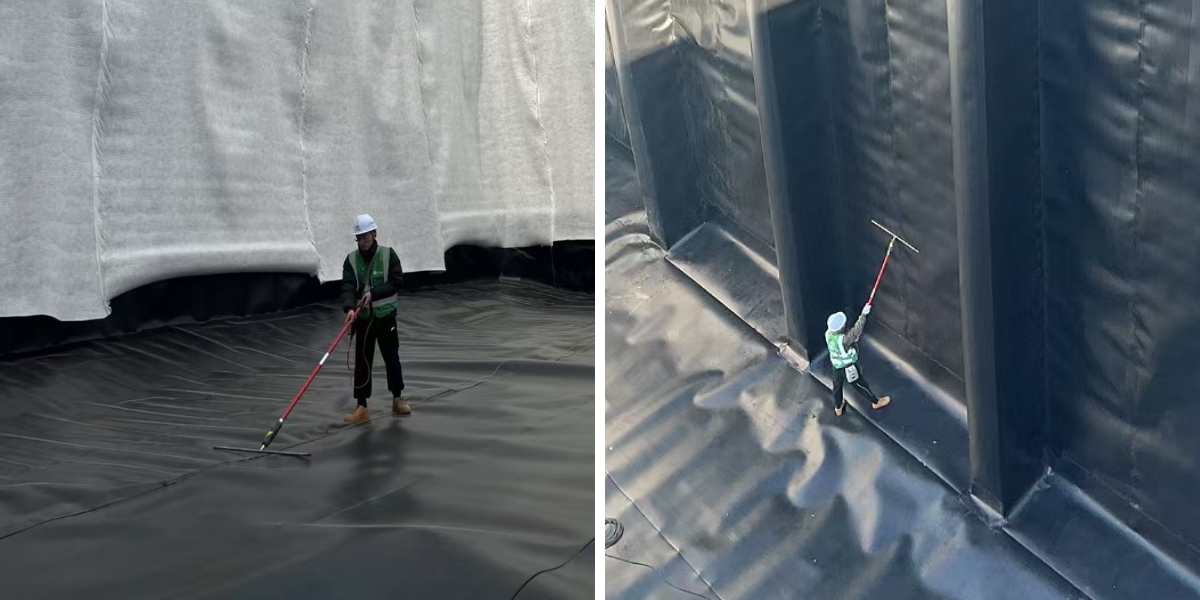

Solution: Installed a thin hdpe geomembrane (cut to fit) and welded it shut.

Result: Leakage dropped to <1%. The farmer saved $3k/year on diesel, and maize yields went up 40%. The geomembrane still works after 5 years.

Case 2: Big Reservoir in California

Problem: A 50-acre reservoir supplied 200+ farms. It leaked 15 million gallons monthly. Old concrete liners (from the 80s) cracked—causing water shortages in the 2022 drought.

Solution: Replaced concrete with an hdpe impermeable liner. Crews welded big sheets together, covering the reservoir in 6 weeks.

Result: Leakage fell to 500,000 gallons monthly (97% better). The reservoir stays full all year—farms have enough water for almonds/grapes. The liner will last 40+ years, saving $2 million.

Case 3: Community Reservoir in India

Problem: A 10-acre reservoir supplied 5,000 people (drinking/farming). Leaks made it dry up 3 months early. Residents walked 5 miles for water. Organic liners broke down in 18 months.

Solution: A local group paid for a hdpe geomembrane. Local workers installed it, adding gravel to protect it from cows/goats.

Result: The reservoir holds water all year. Farmers now grow 2 crops/year (up from 1), and incomes went up 60%. It’s worked 8 years—only one small patch needed.

5. Easy Tips to Install HDPE Geomembrane

Even good hdpe geomembrane fails if installed wrong. Follow these simple steps:

Step 1: Prep the reservoir base

Clean it: Remove rocks, roots, and weeds (they poke holes in the geomembrane).

Compact soil: Use a roller to press soil firm—this stops it from settling and stretching the liner.

Rocky soil? Add 6–12 inches of sand under the hdpe impermeable liner for extra protection.

Step 2: Pick the right HDPE

Small reservoirs (≤5 acres): Use thin HDPE (1.0–2.0mm thick).

Big reservoirs (>5 acres): Use thicker HDPE (2.0–3.0mm)—it handles more water pressure.

Long-term use: Choose “virgin HDPE” (more durable). Add UV protection for outdoor use.

Step 3: Weld seams well

Seams (where sheets meet) leak easiest.

Flat areas: Use a “hot wedge welder” to melt sheets together (1–2 inches wide, no gaps).

Corners/slopes: Use an “extrusion welder” for stronger bonds.

Test 10% of seams: Use air/vacuum tests—reweld if they fail.

Step 4: Protect the liner after install

Add 4–6 inches of topsoil/gravel over it (stops machines/livestock from damaging it).

Secure edges: Use concrete anchors to hold the liner to reservoir banks (stops shifting when filling water).

Put up signs: Warn people not to drive over the liner or dump trash.

Step 5: Check it often

Inspect 2–3 times a year: Look for holes, tears, or sun damage (check near trees/pipes).

Fix small tears fast: Use an HDPE patch kit. Call a pro for big tears (≥6 inches).

Clean debris: Remove leaves/branches from water—rotting stuff damages the liner.

Conclusion: HDPE Geomembrane Is the Best Choice

Leakage in reservoirs doesn’t have to be a problem. Hdpe geomembrane is tough, cheap long-term, and eco-friendly. It’s more waterproof, flexible, and longer-lasting than old liners.

Real stories show it saves water, money, and helps crops grow. Whether you have a small pond or big reservoir, an hdpe impermeable liner pays off for decades.

Ready to stop leaks? Contact a trusted supplier for a quote. They’ll help you pick the right liner—your crops and wallet will thank you!

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province