How Geotextiles Help in Landfill Construction and Waste Management

Landfill building and waste administration are imperative factors of environmental safety and city infrastructure. As international waste technology continues to rise, the want for safe, durable, and eco-friendly landfill services has by no means been extra urgent. Among the a number of substances that beautify landfill performance, geotextiles stand out as a versatile and budget friendly solution. Geotextile Cloth, Non Woven Geotextile Fabric, and different Geotextile merchandise play pivotal roles in addressing frequent challenges in landfill construction—such as soil instability, leachate contamination, bad drainage, and waste containment. This article explores 4 key methods geotextiles revolutionize landfill development and waste management, highlighting their sensible purposes and long-term environmental benefits.

1. Leachate Containment: Preventing Environmental Contamination with Geotextile Cloth

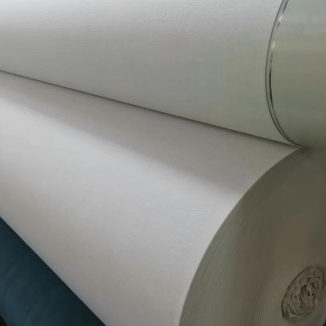

One of the most urgent dangers in landfill operations is leachate—contaminated water shaped when rainwater or groundwater percolates thru waste. Leachate carries detrimental components like heavy metals, natural pollutants, and pathogens, which can seep into soil and groundwater if now not suitable contained. Geotextile Cloth, specifically when blended with geomembranes, creates a sturdy barrier device that minimizes leachate migration.

Non Woven Geotextile Fabric is especially superb in this utility due to its excessive permeability and filtration capabilities. When positioned between the geomembrane and the underlying soil, Non Woven Geotextile Fabric prevents soil particles from clogging the membrane’s pores, making sure the barrier stays intact. Additionally, Geotextile Cloth acts as a shielding layer, protecting the geomembrane from punctures induced with the aid of sharp waste substances or rocky soil. This twin characteristic of containment and safety extensively reduces the hazard of environmental pollution, assisting landfills comply with strict environmental regulations.

In sensible landfill design, the geotextile-leachate barrier machine is set up in the base and facets of the landfill. The Geotextile Cloth’s capacity to face up to chemical degradation from leachate ensures long-term durability, even in harsh landfill environments. This no longer solely protects groundwater assets however additionally reduces the fee of leachate therapy by way of minimizing the quantity of contaminated water that wishes processing.

2. Drainage Enhancement: Maintaining Landfill Stability with Geotextiles

Poor drainage is a important purpose of landfill instability, main to troubles like slope failure, settlement, and accelerated leachate production. Excess water accumulation in the landfill will increase the weight of the waste mass and reduces soil shear strength, posing full-size security risks. Geotextiles play a essential function in enhancing landfill drainage systems, facilitating the environment friendly elimination of water whilst conserving soil particles.

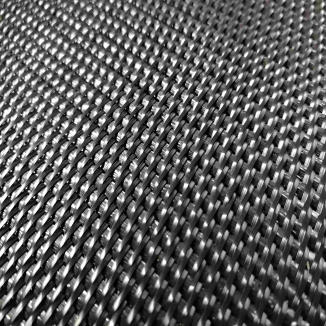

Woven and Non Woven Geotextile Fabric are each used in drainage applications, relying on the precise requirements. Non Woven Geotextile Fabric, with its fibrous structure, approves water to bypass thru whilst filtering out pleasant soil particles, stopping the clogging of drainage pipes and gravel layers. Geotextile Cloth is regularly used as a separator between the drainage layer (e.g., gravel) and the surrounding soil, making sure that the drainage device stays useful over time.

In landfill construction, geotextile-reinforced drainage structures are established in a couple of layers: below the waste mass, along the landfill slopes, and in the leachate series trenches. By efficaciously draining extra water, these structures minimize pore water strain in the soil, improving the general balance of the landfill. This no longer solely extends the lifespan of the landfill however additionally minimizes the hazard of catastrophic failures, defending close by communities and infrastructure.

3. Soil Reinforcement: Strengthening Landfill Foundations with Geotextile Products

Many landfill web sites are positioned on gentle or susceptible soil, which can't assist the heavy weight of the waste mass barring suited reinforcement. Geotextiles are broadly used to decorate the bearing capability of soil, imparting a steady basis for landfill construction. Geotextile reinforcement works with the aid of distributing the load of the waste evenly throughout the soil, lowering agreement and stopping differential movement.

Woven Geotextile Cloth is mainly wonderful for soil reinforcement due to its excessive tensile electricity and modulus. When embedded in the soil, the Geotextile Cloth interacts with the soil particles, transferring the utilized load to the surrounding soil. This will increase the soil’s shear electricity and reduces the chance of slope erosion and collapse. Non Woven Geotextile Fabric can additionally be used in aggregate with woven geotextiles to enhance soil cohesion, specially in sandy or unfastened soil conditions.

In landfill growth projects, geotextile reinforcement is integral for stabilizing the landfill’s edges and making sure that the new waste layers do no longer compromise the current structure. By strengthening the foundation, Geotextiles enable landfills to accommodate greater waste, extending their operational lifestyles and lowering the want for new landfill sites. This no longer solely saves expenses however additionally minimizes the environmental have an effect on of landfill development.

4. Filtration and Separation: Preserving Landfill Integrity with Non Woven Geotextile Fabric

Filtration and separation are indispensable features in landfill construction, as they forestall the mixing of distinctive soil layers and waste materials, which can compromise the landfill’s shape and performance. Geotextiles, particularly Non Woven Geotextile Fabric, excel at these features due to their porous shape and capability to hold first-class particles whilst permitting water to skip through.

In landfill applications, Geotextile Cloth is used to separate the waste mass from the underlying soil, stopping the migration of waste particles into the soil. This separation additionally helps preserve the integrity of the drainage and containment systems, making sure that they function efficiently. Additionally, Non Woven Geotextile Fabric is used in the capping layer of landfills, the place it acts as a filter between the soil cowl and the waste. This prevents the soil from being washed into the waste, which may want to clog drainage structures and amplify leachate production.

The filtration and separation competencies of Geotextiles additionally make contributions to the long-term sustainability of landfills. By retaining the shape of the landfill, these substances limit the want for regular preservation and repairs, decreasing operational costs. Furthermore, they assist hold the landfill’s potential via stopping the loss of usable area due to soil mixing and clogging.

Conclusion: The Indispensable Role of Geotextiles in Sustainable Waste Management

Geotextiles—including Geotextile Cloth and Non Woven Geotextile Fabric—are imperative substances in contemporary landfill building and waste management. Their capability to include leachate, decorate drainage, toughen soil, and grant fantastic filtration and separation addresses the key challenges confronted by way of landfill operators. By incorporating geotextiles into landfill design, we can create safer, extra durable, and extra environmentally pleasant waste administration facilities.

As the world demand for sustainable waste administration options grows, the use of Geotextile merchandise will proceed to expand. Their cost-effectiveness, versatility, and long-term sturdiness make them a clever funding for landfill projects, supporting to guard the surroundings and make certain the environment friendly use of landfill resources. Whether in new landfill development or the rehabilitation of present sites, geotextiles play a imperative function in building a greater sustainable future for waste management.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province