How to Install HDPE Geomembrane for Maximum Sealing Performance

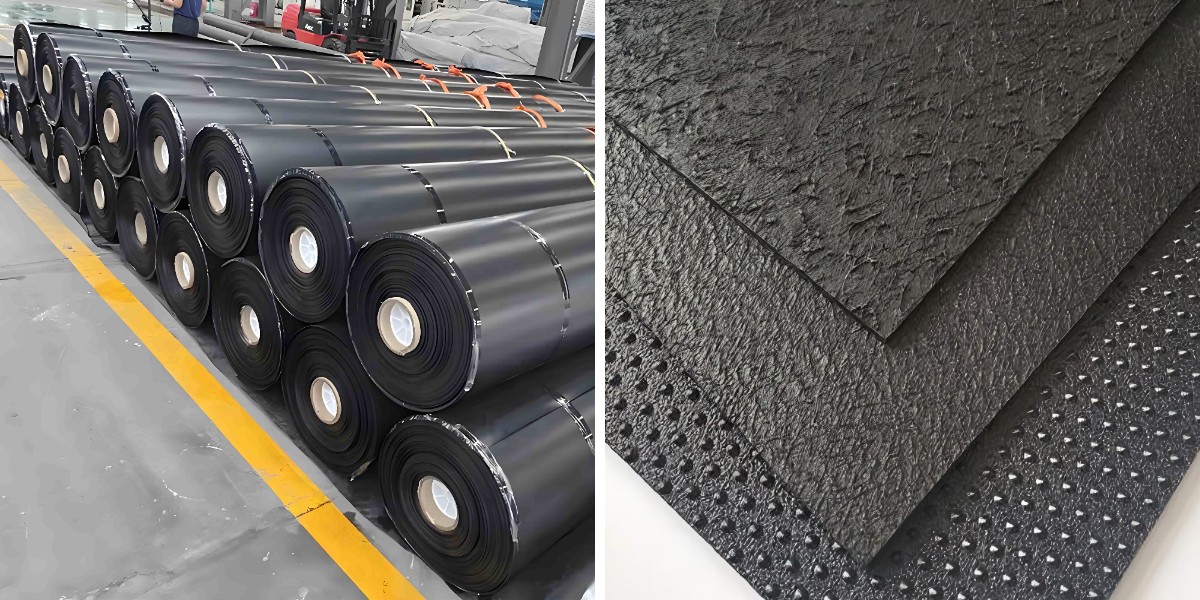

HDPE geomembrane is a pinnacle preference for tightly closed boundaries in engineering projects, from landfills to water reservoirs. As a high-performance invulnerable geomembrane, its sealing impact relies upon mostly on perfect installation. Follow this step-by-step information to make sure your HDPE geomembrane offers long-lasting, leak-free performance.

1. Pre-Installation Preparation: Lay the Groundwork

Before laying any geomembrane, website coaching is critical—especially for an invulnerable geomembrane like HDPE. Start by using clearing the vicinity of rocks, roots, and particles that should puncture the material. Use a curler to compact the soil, growing a smooth, association base.

For tasks the usage of clean geomembrane (a frequent HDPE variant), make certain the subgrade has a slope of much less than 5% to forestall shifting. If working on sloped surfaces, test that the grade is secure and free of unfastened soil. Finally, measure the set up region to calculate the specific quantity of HDPE geomembrane needed, accounting for overlaps (typically 10–15 cm for seams).

2. Unrolling and Positioning: Handle with Care

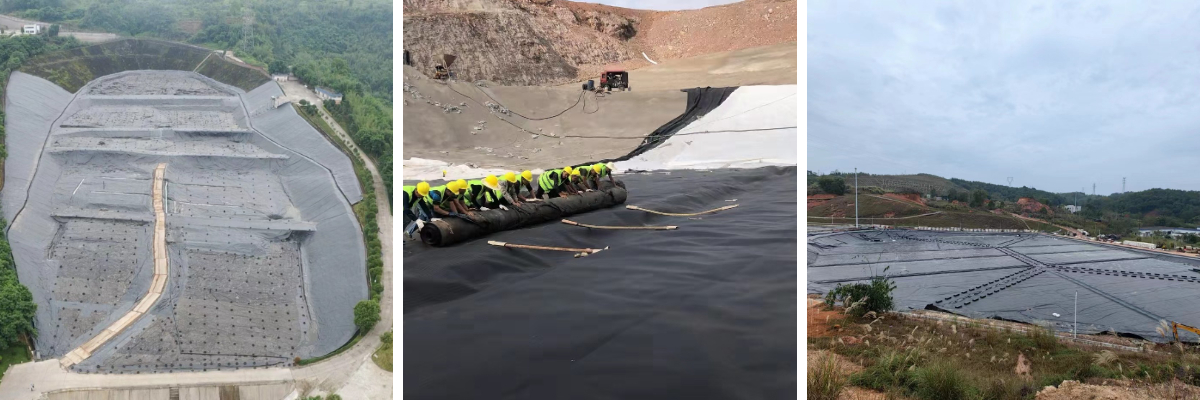

Once the web page is prepped, unroll the HDPE geomembrane cautiously to keep away from creases or tears. For massive projects, use equipment to carry and role the rolls, however maintain the cloth taut to stop sagging.

Smooth geomembrane requires more interest in the course of unrolling—avoid dragging it throughout hard surfaces, as this can injury its secure layer. Align the sheets so that seams overlap uniformly; uneven overlaps are a frequent purpose of leaks in impenetrable geomembrane systems. If putting in on slopes, begin from the backside and work upward to keep control.

3. Seaming Techniques: The Key to Impermeability

Seaming is the place an HDPE geomembrane’s sealing overall performance is make-or-break. For most strength, use thermal fusion welding—the gold trendy for invulnerable geomembrane joints.

Thermal Welding: Use a wedge welder to warmth the overlapping edges of the HDPE geomembrane to 180–200°C, fusing them into a single, non-stop barrier. Test 3–5 sample seams first to alter temperature and speed.

Extrusion Welding: For corners or tight spaces, use an extrusion welder to follow molten HDPE alongside the seam. This is perfect for easy geomembrane, as it fills gaps evenly.

After welding, look at every seam with a stress tester. A accurate sealed seam have to preserve air stress for at least 30 seconds—any drop suggests a vulnerable spot.

4. Post-Installation Inspection: Catch Issues Early

Even the satisfactory HDPE geomembrane desires a last check. Walk the complete set up vicinity to seem for:

Punctures or tears, in particular round edges or close to heavy tools paths.

Loose seams that may want to compromise the secure geomembrane’s integrity.

Bubbles or wrinkles in easy geomembrane, which can lure water and motive long-term damage.

For massive projects, use non-destructive checking out like spark trying out to notice pinholes. Mark and restore any troubles without delay with HDPE patches welded into place.

5. Maintenance Tips: Extend Sealing Performance

To maintain your HDPE geomembrane working for decades:

Avoid setting heavy objects on the surface, as they can stress the invulnerable geomembrane.

Trim vegetation close to the edges to forestall roots from piercing the material.

Inspect seams annually, mainly after severe weather. For easy geomembrane, take a look at for symptoms of UV degradation, which can weaken the floor over time.

Why HDPE Geomembrane Stands Out

As an secure geomembrane, HDPE outperforms many alternatives. Its chemical resistance makes it best for industrial containment, whilst clean geomembrane editions simplify set up on flat surfaces. When hooked up correctly, it creates a barrier that stops leaks, protects soil and water, and reduces long-term preservation costs.

By following these steps, you’ll make certain your HDPE geomembrane offers most sealing performance—keeping your mission secure and sustainable for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province