HDPE Geomembrane FAQs: Answers to Contractors’ Most Pressing Questions

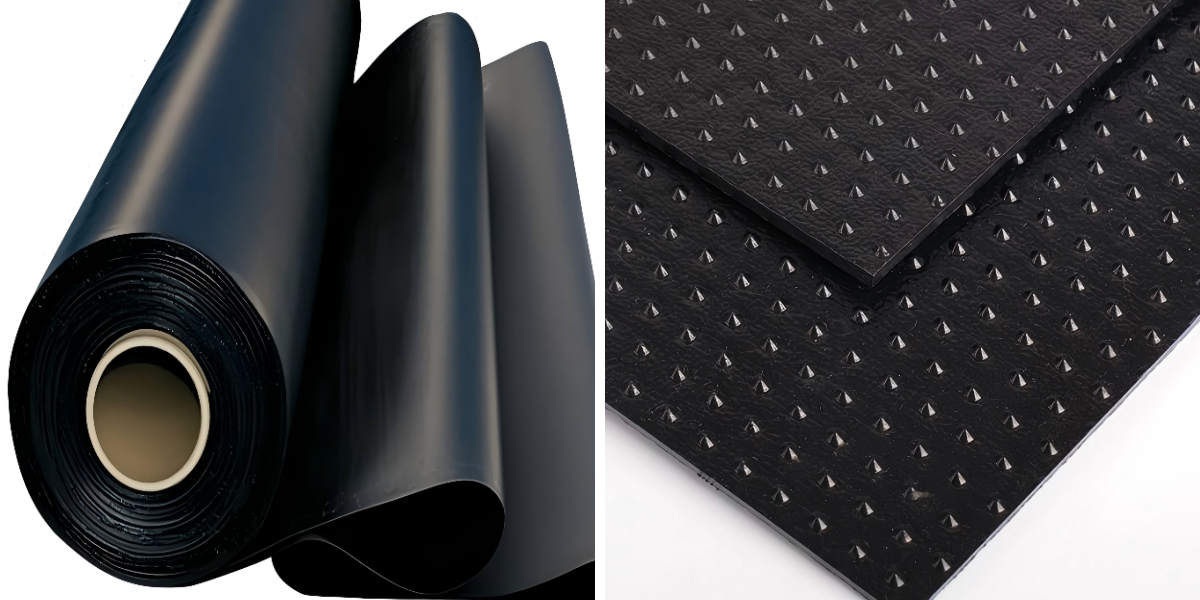

As a necessary fabric in anti-seepage engineering, HDPE geomembrane is extensively used in landfills, reservoirs, river regulation, and mining reclamation projects. However, contractors regularly face a range of puzzles all through cloth selection, geomembrane installation, and exceptional control. This article compiles the most urgent FAQs about HDPE geomembrane, offering expert and actionable solutions to assist you optimize development procedures and make certain assignment durability.

1. Material Selection FAQs: How to Choose the Right HDPE Geomembrane for Your Project?

Selecting the fantastic HDPE geomembrane is the basis of a profitable anti-seepage project. Contractors regularly conflict with thickness selection, cloth overall performance requirements, and matching merchandise to unique assignment scenarios. Below are exact solutions to these frequent questions:

Q1: What thickness of HDPE geomembrane need to I pick out for exclusive projects?

The thickness of HDPE geomembrane immediately impacts its anti-seepage impact and carrier life, and the choice ought to be based totally on task type, environmental conditions, and stress levels. For landfill projects, which require excessive anti-puncture and corrosion resistance, a thickness of ≥1.5mm HDPE geomembrane is endorsed to face up to the stress of rubbish stacking and face up to chemical erosion from leachate. For reservoirs, fish ponds, and regular water conservancy projects, 1.0-1.2mm HDPE geomembrane is typically sufficient, whilst composite geomembrane (two cloths and one membrane) is favored for tasks wanting root penetration resistance. For tailings ponds with harsh environmental conditions, improved HDPE geomembrane with thickness ≥2.0mm is required to face up to temperature adjustments and robust chemical corrosion.

Q2: What key overall performance indications have to I pay interest to when buying HDPE geomembrane?

When buying HDPE geomembrane, focal point on core overall performance warning signs such as tensile strength, elongation at break, anti-seepage coefficient, and UV resistance. Qualified HDPE geomembrane must have a tensile power of no longer much less than 14.2MPa and a thermal welding peel power of no longer much less than 11.4MPa. The anti-seepage coefficient must attain 10⁻¹¹ cm/s or greater to make certain fantastic anti-seepage performance. In addition, for outside initiatives uncovered to long-term sunlight, choose merchandise with delivered anti-UV marketers to stop power degradation due to aging. It is additionally imperative to take a look at the look high-quality of the membrane, making sure no bubbles, cracks, or thickness deviations (controlled inside ±10%).

Q3: Is there a distinction between HDPE geomembrane and different sorts of geomembrane? When to select HDPE?

Compared with PVC, EVA, and different geomembrane materials, HDPE geomembrane has most effective corrosion resistance, excessive mechanical strength, and higher long-term durability. It is particularly appropriate for tasks with harsh environments such as chemical corrosion and robust UV radiation. PVC geomembrane has higher flexibility however terrible chemical resistance, making it unsuitable for acidic and alkaline environments. EVA geomembrane has suitable low-temperature flexibility however decrease tensile electricity than HDPE. Therefore, HDPE geomembrane is the first desire for landfills, chemical storage tanks, tailings ponds, and different tasks requiring long-term anti-seepage and corrosion resistance.

2. Geomembrane Installation FAQs: Key Points to Avoid Common Construction Errors

Geomembrane set up satisfactory immediately determines the project's anti-seepage effect. Common issues such as weld cracking, membrane damage, and fallacious lap joint coping with regularly manifest all through construction. The following solutions focal point on core set up links:

Q1: What are the key necessities for base therapy earlier than geomembrane installation?

Base remedy is a vital prerequisite for geomembrane installation. First, behavior on-site surveys to verify that the groundwater degree and basis bearing capability meet plan requirements; tender foundations or waterlogged areas want pre-replacement and drainage. The base need to be compacted in layers with a roller, and the compaction diploma need to no longer be decrease than the graph value. Manually take away gravel large than 2cm in diameter and tree roots, and backfill depressions with graded sand and gravel to make sure the base is flat and free of sharp objects that ought to pierce the membrane. Before installation, the base have to be saved easy and dry; no debris, oil, or moisture is allowed on the surface.

Q2: What are the technical necessities for HDPE geomembrane welding?

Welding is the core hyperlink of HDPE geomembrane installation, and two important techniques are used: double-seam thermal welding and single-seam extrusion welding. For large-area welding, double-seam thermal welding is preferred, with a lap width of 80-100mm (imported tools requires 100mm, home made gear 80mm). Before formal welding, smooth the 200mm vary of the lap joint with a damp material to preserve it smooth and dry. Set welding parameters (temperature 250-300℃, pace 15-25m/min) and habits a check weld with 300×600mm membrane pieces. The weld have to pass by shear and peel tests—only membrane tearing is allowed, no longer weld damage. For different components such as pipes and corners, use extrusion welding with a lap width ≥60mm, and the weld middle thickness have to be 2.5 instances the liner thickness (not much less than 3mm).

Q3: What environmental prerequisites are now not appropriate for geomembrane set up and welding?

Environmental elements drastically have an effect on HDPE geomembrane set up quality. Welding is prohibited when the ambient temperature is greater than 40℃ or decrease than 0℃; when the temperature is between 0-5℃, preheat the welding laptop and membrane earlier than construction. Construction have to no longer be carried out on wet days or when humidity exceeds 80% to keep away from affecting weld bonding. For slope set up with a gradient higher than 1:3, welders and auxiliary personnel ought to function on tender ladders with security belts; for steep slopes or vertical surfaces, use striking baskets or straight ladders, and set constant factors at the pinnacle of the slope to aid in controlling the welding machine's lifting.

Q4: How to deal with distinct components such as corners, pipes, and concrete connections all through installation?

Special components are susceptible to leakage and require cautious handling. For corners, use arc gaskets to keep away from stress concentration, and reduce the membrane into terrific shapes to make certain shut becoming barring wrinkles. For pipe penetration, reduce the membrane into a "bell mouth" for wrapping, and the lap joint ought to be at least 20cm away from the shape edge; use extrusion welding to enhance and shape a composite seal with thermal welding. For connections between HDPE geomembrane and concrete, use concrete connecting locks embedded in concrete, then extrusion weld the membrane to the lock's welding surface. Avoid pass welding at all times; adjoining welds ought to be staggered via at least 50cm, forming T-joints alternatively of go joints, and fortify T-joints with extrusion welding or patches.

3. Quality Inspection & Maintenance FAQs: Ensuring Long-Term Project Performance

Post-installation first-rate inspection and long-term protection are integral to lengthen HDPE geomembrane provider life. Contractors regularly have questions about inspection methods, harm repair, and each day maintenance. Below are expert answers:

Q1: What techniques are used to investigate HDPE geomembrane weld quality?

Weld high-quality inspection consists of look inspection and tightness testing. Appearance inspection requires welds to be flat, neat, free of bubbles or skips, and with uniform bead height. Tightness checking out in most cases makes use of vacuum checking out and air inflation testing. For double-seam welds, use air inflation testing: inflate to 0.2-0.3MPa and hold strain for 15 minutes; a strain drop ≤10% suggests qualification. For single-seam welds and small areas, use vacuum testing: observe a vacuum cowl with terrible strain ≥25kPa and hold for 30 seconds; no bubbles point out qualification. Randomly choose 1 set of samples for tensile trying out each and every 1000m of welds; the fracture must take place in the base material, now not the weld. The inspection ratio need to no longer be much less than 10% for accepted areas and improved to 20% for repaired areas.

Q2: How to restore HDPE geomembrane injury discovered at some stage in inspection or operation?

Repair strategies rely on harm size. For small injury (diameter <5cm), reduce a same-material membrane patch (side size ≥10cm), use a warm air welding gun to weld round the patch with a width ≥3cm, and check with a vacuum cover after welding. For massive injury (>1m²), reduce out the broken area, re-lay and weld new membrane, and look into the welds in accordance to set up standards. For weld cracking, take away the historic weld, re-weld, and behavior double-length inspection. When repairing, make sure the membrane floor is smooth and dry, and the patch edges are rounded to keep away from stress concentration. For emergency treatment, briefly cowl with a damp fabric or water-resistant tape.

Q3: What are the key factors for each day upkeep and long-term monitoring of HDPE geomembrane?

Daily upkeep consists of weekly visible inspections, focusing on welds, slopes, and corners. Increase inspection frequency after rain or excessive climate and document damage, displacement, or bulging. For dynamic initiatives such as landfills, display the affect of protecting layer compaction and rubbish stacking on the membrane, warding off direct heavy equipment rolling. Clean the membrane floor with impartial detergent and heat water for oil stains, and tender brushes for sediment; do now not use robust acids or alkalis. Exposed membranes need to be included with sunshades (avoiding direct daylight for greater than 30 days) or sprayed with anti-UV coatings. Long-term monitoring have to consist of stress monitoring (install stress gauges at slopes and corners) and leakage monitoring (install leakage detection layers beneath the anti-seepage system), and take well timed measures when indications exceed format limits.

Final Thoughts

HDPE geomembrane's overall performance in anti-seepage tasks relies upon on scientific cloth selection, standardized geomembrane installation, and strict satisfactory control. By addressing the above FAQs, contractors can correctly keep away from frequent pitfalls and make certain mission quality. Whether choosing the proper HDPE geomembrane thickness, learning welding techniques, or enforcing appropriate maintenance, adhering to enterprise requirements and satisfactory practices is key. If you have greater project-specific questions, seek advice from expert geomembrane producers or engineering technicians for personalized solutions.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province