HDPE Geomembrana: The Ultimate Guide to Its Uses in Wastewater Treatment Plants

Wastewater cure flowers (WWTPs) are vital for defending public fitness and the environment— however their effectiveness hinges on one often-overlooked component: dependable containment. Leaks in tanks, lagoons, or sludge areas can launch detrimental contaminants into soil and groundwater, main to high-priced cleanups, regulatory fines, and long-term ecological damage. This is the place HDPE geomembrana (high-density polyethylene geomembrane) shines. As a robust, flexible, and noticeably impermeable solution, it outperforms standard substances in sturdiness and leak prevention. Below, we smash down 5 key approaches HDPE geomembrana transforms wastewater cure operations, with a center of attention on its position as a hdpe liner, geomembrane, and impermeable geomembrane liner.

1. The Core Role of HDPE Geomembrana: Stopping Leaks as an Impermeable Geomembrane Liner

At its heart, HDPE geomembrana serves as the first line of protection towards leaks in WWTPs— functioning as a top rate impermeable geomembrane liner. Unlike porous substances (such as concrete or clay liners) that enhance cracks over time, HDPE geomembrana boasts a near-zero permeability rate, blocking off even the smallest molecules of wastewater, chemicals, or sludge from seeping into the ground.

This impermeability is imperative for WWTP elements like aeration tanks, equalization basins, and sludge digestion facilities. For example, aeration tanks— which deal with natural depend the use of bacteria— incorporate excessive concentrations of ammonia and nitrates. A inaccurate liner right here ought to contaminate groundwater, rendering it risky for ingesting or irrigation. HDPE geomembrana eliminates this risk: its dense molecular shape resists chemical degradation and stays intact even underneath steady publicity to wastewater. Additionally, as a bendy geomembrane, it adapts to floor motion (common in older WWTPs) barring cracking— a fundamental gain over inflexible liners that fail below stress. WWTP operators document a 95% discount in leak-related incidents after switching to HDPE geomembrana as their predominant hdpe liner.

2. Key Applications in WWTPs: From Lagoons to Sludge Storage

HDPE geomembrana isn’t a one-size-fits-all solution— it’s tailor-made to tackle the special wishes of distinctive WWTP zones. Here are three quintessential purposes the place this geomembrane excels:

Lagoon Liners

Wastewater lagoons (used for principal or secondary treatment) count on liners to preserve giant volumes of water for weeks or months. HDPE geomembrana is best right here due to the fact its UV-resistant houses forestall degradation from sunlight— a frequent trouble with more cost effective plastic liners that spoil down in out of doors settings. As an impermeable geomembrane liner, it additionally withstands the weight of amassed wastewater and resists punctures from particles or aquatic life. Lagoons lined with HDPE geomembrana require 50% much less protection than these with clay liners, as they don’t want periodic re-compacting to restore cracks.

Sludge Storage Facilities

Sludge— the stable byproduct of wastewater treatment— is relatively centred with heavy metals and pathogens. Storing it safely requires a liner that can cope with excessive weight and withstand chemical corrosion. HDPE geomembrana (as a heavy-duty hdpe liner) meets this need: its thick gauge (typically 1.5mm to 3mm) helps the weight of dewatered sludge, whilst its chemical resistance prevents degradation from acids or alkalis in the sludge. Many WWTPs now use HDPE geomembrana in sludge drying beds, the place it additionally enables less difficult cleaning— the clean floor of the geomembrane prevents sludge from sticking, lowering cleanup time by means of 30%.

Chemical Storage Tanks

WWTPs use chemical substances like chlorine and alum for disinfection and coagulation. These chemical substances are corrosive, so their storage tanks want liners that won’t smash down. HDPE geomembrana acts as a defensive impermeable geomembrane liner inner these tanks, developing a barrier between the metallic tank and the chemicals. Unlike rubber liners that swell or degrade in contact with chlorine, HDPE geomembrana continues its integrity, making sure no poisonous chemical substances leak into the facility or surrounding soil.

3. Installation & Maintenance: Ensuring Longevity of Your HDPE Liner

Even the pleasant geomembrane fails besides desirable installation— and HDPE geomembrana is no exception. Follow these nice practices to maximize the lifespan of your hdpe liner in WWTPs:

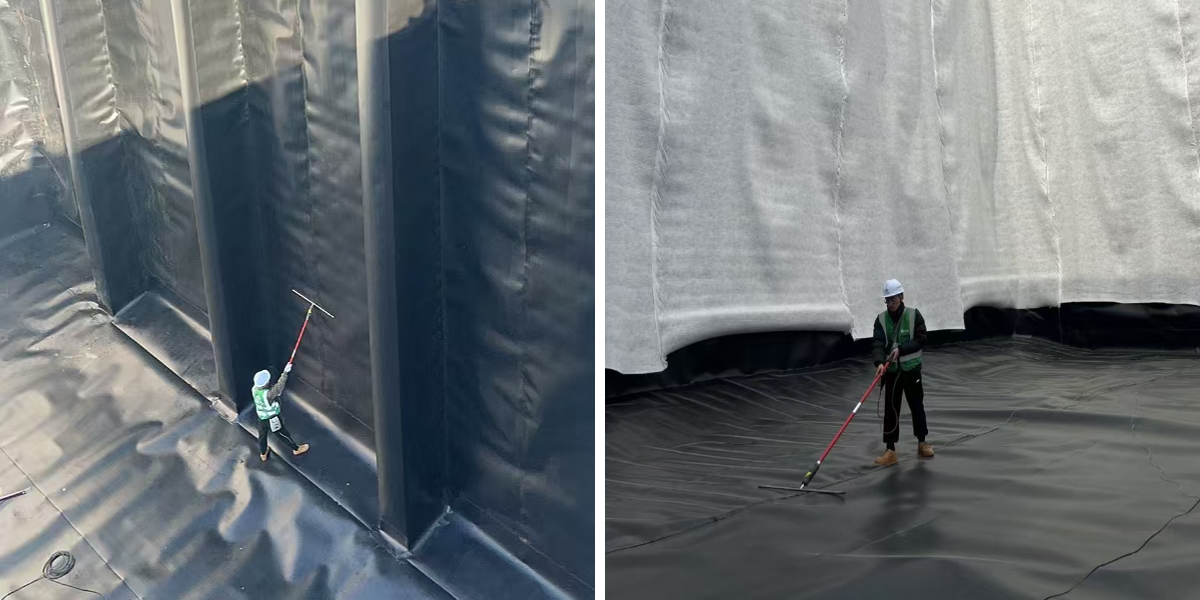

Pre-Installation Preparation

Before laying HDPE geomembrana, the website online ought to be cleared of rocks, roots, and sharp particles that ought to puncture the liner. The floor have to additionally be graded to create a smooth, even surface— uneven terrain can reason stress factors that lead to cracks. Many contractors use a non-woven geotextile underlay (paired with the impermeable geomembrane liner) to add an greater layer of safety in opposition to punctures.

Welding & Seaming

The most imperative step in installing HDPE geomembrana is developing watertight seams. Heat fusion welding— the fashionable technique for hdpe liner installation— melts the edges of the geomembrane together, forming a bond improved than the cloth itself. WWTP tasks require a hundred percent seam checking out (using vacuum or air strain tests) to make sure no gaps exist. A single inaccurate seam can lead to a principal leak, so this step is non-negotiable.

Routine Maintenance

While HDPE geomembrana is low-maintenance, ordinary inspections are key. Every 6 months, take a look at for symptoms of damage: tears, punctures, or seam separation. For lagoons or outside tanks, dispose of particles (like branches or algae) that should rub in opposition to the geomembrane and motive wear. If small tears are found, restore them without delay the use of HDPE patch kits— delaying repairs can lead to larger, more expensive issues. With desirable care, HDPE geomembrana can closing 20-30 years, making it a long-term funding for WWTPs.

4. Why HDPE Geomembrana Outperforms Other Geomembrane Materials

WWTP operators have alternatives when it comes to liners— however HDPE geomembrana stands out for three key reasons:

Superior Durability

Compared to PVC or EPDM geomembranes, HDPE geomembrana is greater resistant to chemicals, UV rays, and bodily damage. PVC liners, for example, can grow to be brittle in daylight and degrade when uncovered to sturdy chemical substances (like chlorine). EPDM liners, while flexible, are susceptible to punctures from sharp objects. HDPE geomembrana, by using contrast, keeps its power and flexibility in harsh WWTP conditions— even after a long time of use.

Cost-Efficiency

While HDPE geomembrana has a greater upfront fee than clay or PVC liners, it saves cash in the lengthy run. As a low-maintenance hdpe liner, it reduces restore and alternative costs: clay liners want re-compacting each 5-7 years (costing heaps of dollars), whilst PVC liners usually want substitute after 10 years. HDPE geomembrana’s 20-30 12 months lifespan potential fewer disruptions to WWTP operations and decrease complete possession costs.

Environmental Safety

As an impermeable geomembrane liner, HDPE geomembrana prevents infection of soil and groundwater— a integral component for WWTPs searching to meet environmental regulations. It’s additionally recyclable at the stop of its lifespan, making it a extra sustainable desire than non-recyclable liners. Many WWTPs use HDPE geomembrana to attain inexperienced certifications, as it aligns with desires for decreasing environmental impact.

5. Compliance & Standards: Choosing HDPE Geomembrana for Regulatory Approval

WWTPs function underneath strict guidelines (such as the U.S. EPA’s Clean Water Act or the EU’s Urban Waste Water Treatment Directive) that mandate leak-proof containment. Choosing the proper geomembrane is quintessential for compliance— and HDPE geomembrana is designed to meet these standards.

Look for HDPE geomembrana that meets enterprise certifications like ASTM D4332 (standard for geomembranes) or GRI-GM13 (guideline for HDPE geomembranes). These certifications make sure the hdpe liner has been examined for permeability, chemical resistance, and durability— giving regulators self belief that your WWTP is covered in opposition to leaks. Additionally, HDPE geomembrana’s impermeability fee (typically much less than 1x10^-9 cm/s) exceeds the minimal necessities for most regulatory bodies, making it less difficult to bypass inspections.

For WWTPs present process improvements or new construction, the use of HDPE geomembrana as an impermeable geomembrane liner can velocity up the approval process. Regulators understand it as a proven, dependable solution— lowering the chance of delays due to non-compliant liners.

Conclusion: Invest in HDPE Geomembrana for a Leak-Free, Compliant WWTP

Wastewater cure plant life can’t find the money for to reduce corners on containment— and HDPE geomembrana offers the reliability, durability, and compliance wished to shield operations and the environment. As a top-tier hdpe liner, geomembrane, and impermeable geomembrane liner, it solves the largest challenges WWTPs face: leaks, preservation costs, and regulatory pressure.

Whether you’re lining a lagoon, storing sludge, or defending chemical tanks, HDPE geomembrana adapts to your desires and gives many years of performance. By selecting this solution, you’re no longer simply investing in a liner— you’re investing in the long-term success and sustainability of your wastewater cure plant. Make the swap to HDPE geomembrana today, and experience peace of thinking understanding your facility is leak-free and compliant.

Contact Us

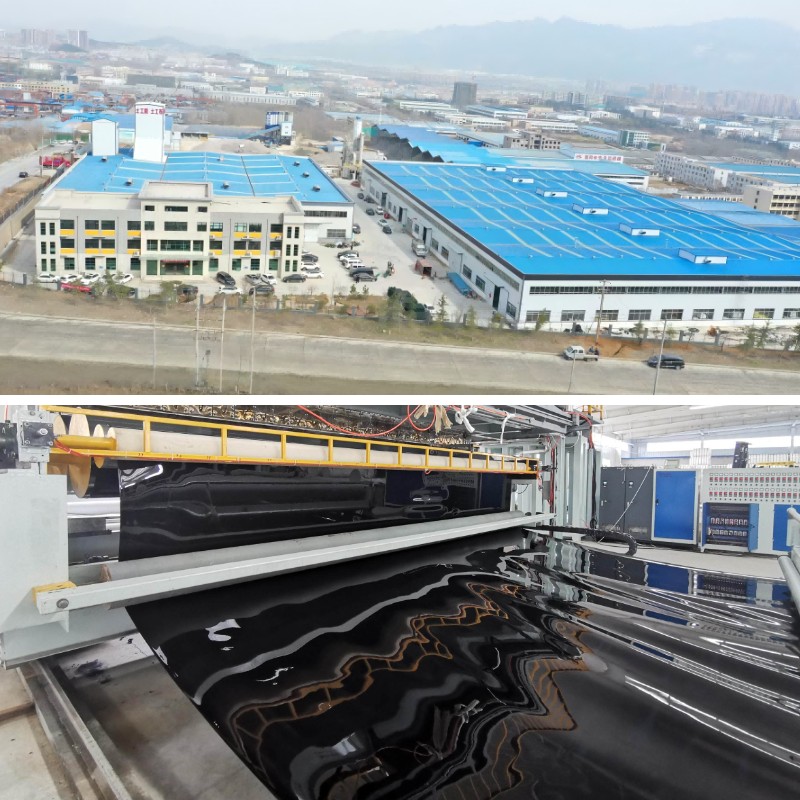

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province