HDPE Geocell Seaming & Connection Techniques: Ensuring a Unified, Stable Grid

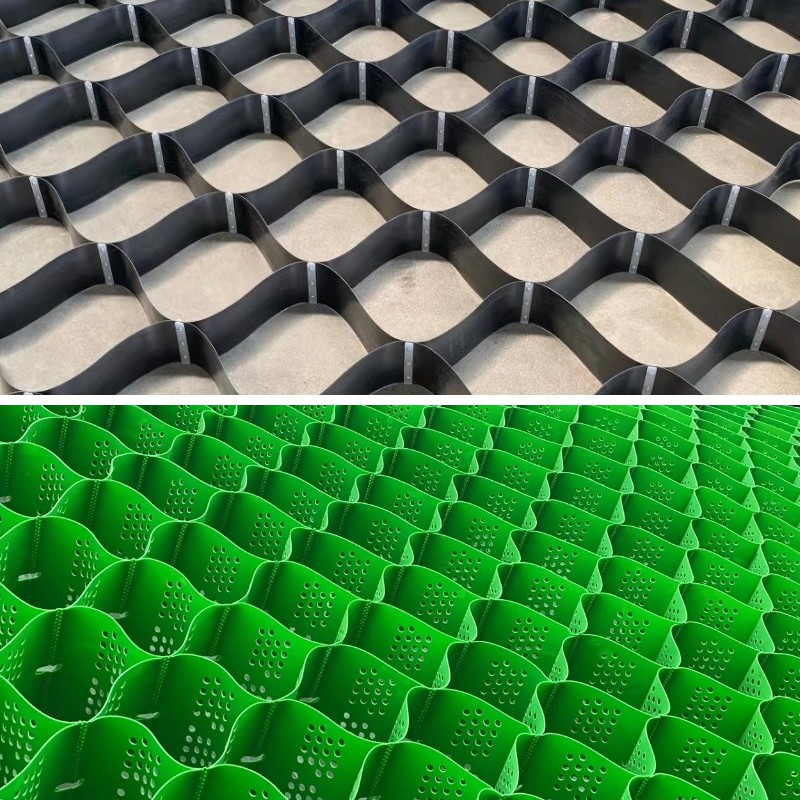

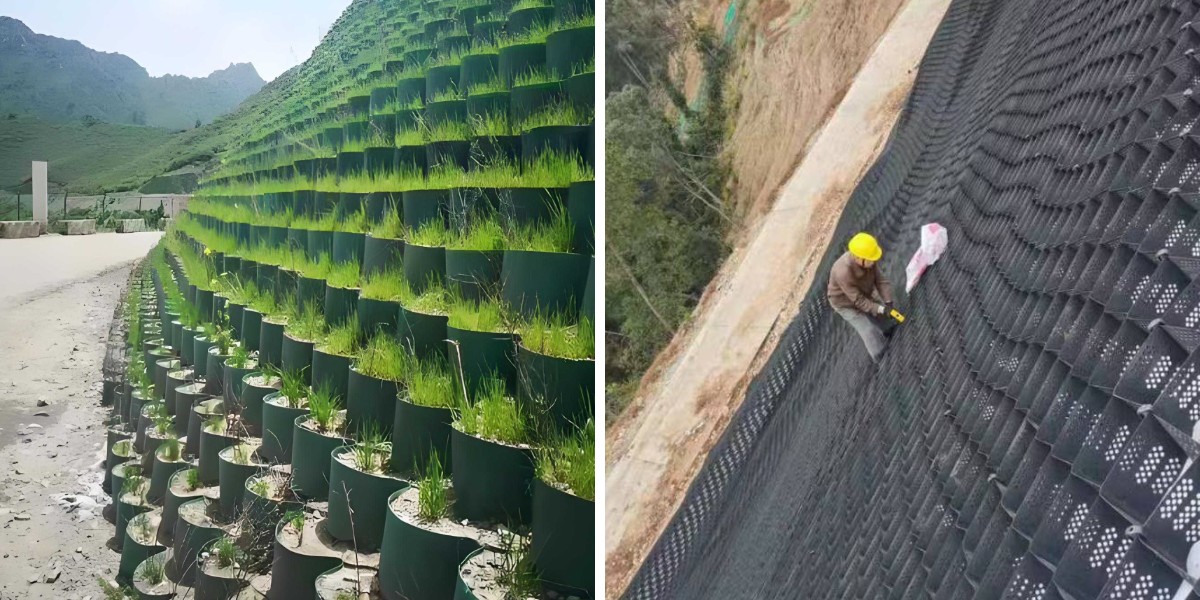

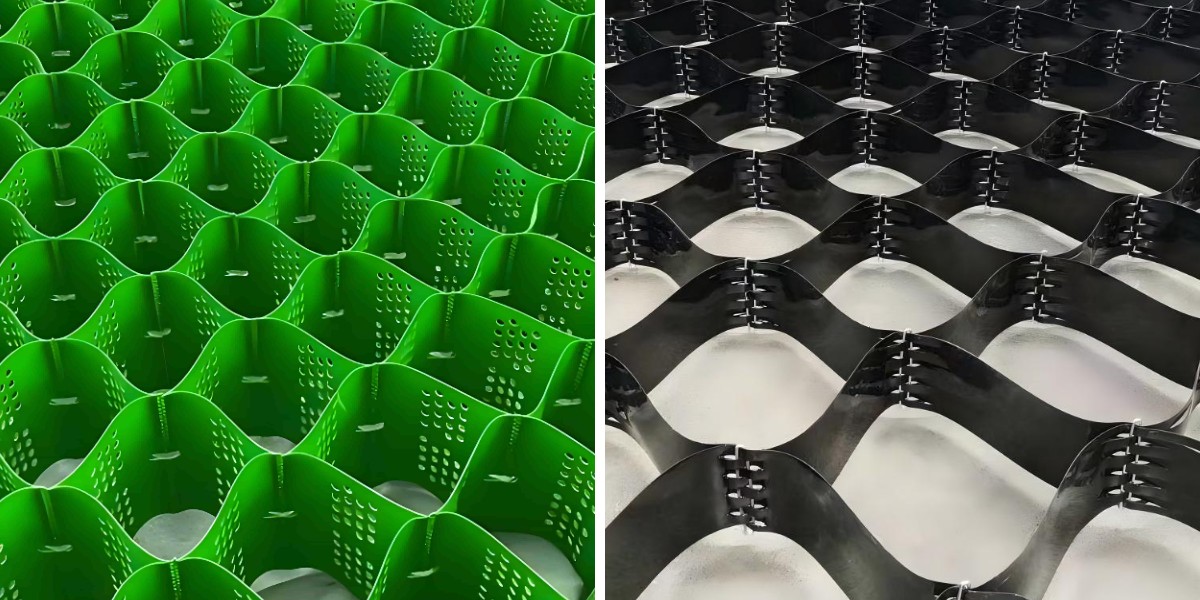

HDPE geocell, a third-dimensional honeycomb shape made of high-density polyethylene, has end up a cornerstone in geotechnical engineering, specifically for soil stabilization, slope reinforcement, and street construction. As a kind of geoweb systems, its overall performance depends closely on the integrity of seaming and connections—weak joints can compromise the whole grid’s stability, main to infrastructure failure. For functions like avenue building geocell, the place load-bearing ability and long-term sturdiness are non-negotiable, learning suitable seaming and connection strategies is critical. This article explores three key elements of HDPE geocell seaming and connection, protecting core methods, high-quality manipulate measures, and tailor-made purposes in street construction, to assist authorities reap a unified, secure grid.

1. Core Seaming & Connection Methods for HDPE Geocell: Matching Techniques to Project Needs

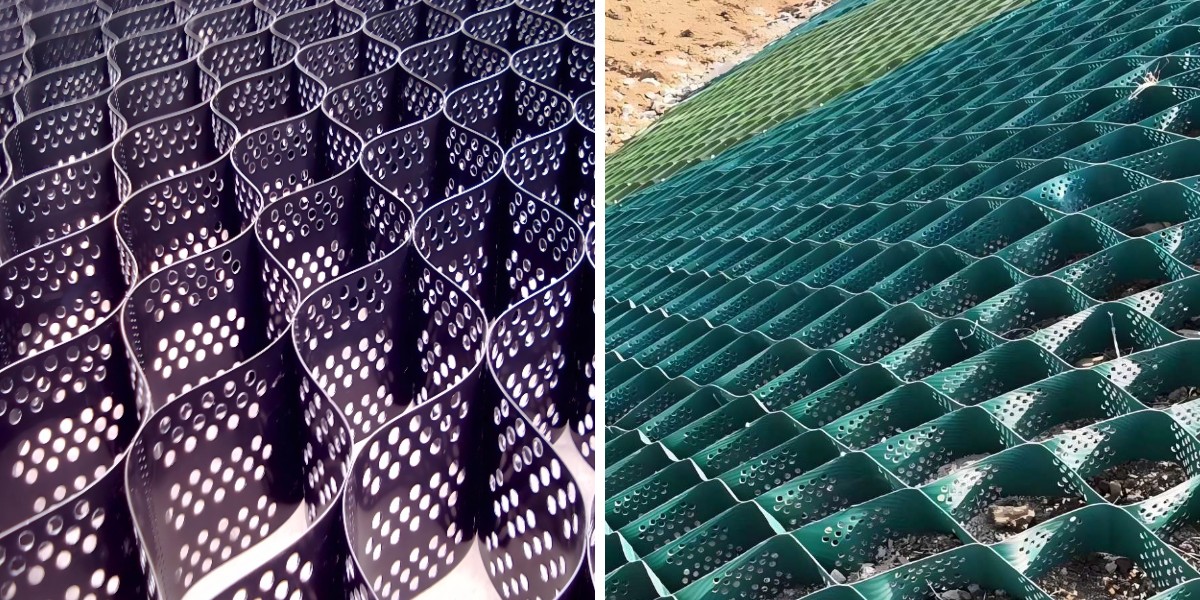

The effectiveness of HDPE geocell structures relies upon on deciding on the proper seaming and connection method, as one of a kind initiatives demand various stages of strength, flexibility, and set up efficiency. Geoweb structures producers generally advise three predominant techniques—thermal welding, mechanical fasteners, and adhesive bonding—each with special benefits and best use cases. Understanding the nuances of every approach ensures that the geocell grid stays intact beneath operational stresses.

Thermal welding is the most broadly used approach for HDPE geocell seaming, particularly in large-scale infrastructure initiatives like avenue development geocell applications. This method makes use of warmness to fuse HDPE panels at their edges, developing a permanent, homogeneous bond with electricity related to the base material. Hot air welding and extrusion welding are the two essential thermal welding subtypes: warm air welding is appropriate for flat, straight seams, the use of heated air to soften the HDPE surfaces earlier than compressing them together; extrusion welding is best for curved seams, corners, or repairs, the place a molten HDPE rod is extruded into the joint to shape a strong bond. Thermal welding’s key gain is its resistance to water, UV radiation, and chemical erosion, making it best for out of doors and high-stress environments.

Mechanical fasteners, such as bolts, nuts, and clips, provide a flexible, detachable connection choice for HDPE geocell. This approach is desired for brief structures, small-scale projects, or areas the place thermal welding is impractical (e.g., bloodless climates with sub-zero temperatures). Mechanical connections contain drilling holes in the geocell panels and securing them with corrosion-resistant fasteners, making sure a tight healthy whilst permitting for minor changes in the course of installation. However, it’s essential to observe that mechanical fasteners create practicable stress points, so they are now not encouraged for major load-bearing seams in everlasting street development or slope stabilization projects.

Adhesive bonding makes use of specialised HDPE-compatible adhesives to bond geocell panels. This approach is speedy to deploy and appropriate for small repairs or tasks with confined get right of entry to to welding equipment. While adhesive bonding affords precise preliminary strength, it is much less long lasting than thermal welding, as adhesives can degrade over time due to UV exposure, moisture, and temperature fluctuations. For this reason, adhesive bonding is usually used as a supplementary method instead than a essential seaming approach for imperative geoweb structures applications.

2. Quality Control & Inspection: Safeguarding HDPE Geocell Grid Integrity

Even the most superior seaming and connection strategies fail besides rigorous first-class manage (QC) and inspection processes. For HDPE geocell systems, QC measures have to be carried out at each stage—from fabric guidance to post-installation testing—to make sure that seams and connections meet enterprise standards and venture specifications. This is especially imperative for street development geocell projects, the place substandard joints can lead to potholes, pavement settlement, or even street failure.

Pre-installation QC starts offevolved with verifying the best of HDPE geocell substances and seaming supplies. Geocell panels must be free of defects like cracks, tears, or thickness inconsistencies, as these can weaken seams. Welding tools have to be calibrated commonly to make sure correct temperature control—HDPE requires a unique temperature vary (typically 200–230°C) for most advantageous fusion; temperatures that are too low end result in vulnerable bonds, whilst immoderate warmth can degrade the material. For mechanical fasteners and adhesives, inspectors ought to affirm that merchandise are well matched with HDPE and meet corrosion resistance and electricity requirements.

During installation, real-time inspection is essential. For thermal welding, inspectors must take a look at seam width (typically 20–30 mm), fusion uniformity, and the absence of gaps or bubbles. A frequent check is the “peel test”: after welding, a small area of the seam is pulled aside to make certain that the bond fails in the base fabric (not the seam itself), indicating a sturdy fusion. For mechanical connections, inspectors affirm that fasteners are good tightened and evenly spaced, with no harm to the geocell panels round the holes. Adhesive bonds have to be inspected for full insurance and absence of peeling or lifting.

Post-installation checking out ensures long-term seam performance. Non-destructive assessments like ultrasonic trying out can notice inner defects in thermal seams, whilst load-bearing assessments consider the complete geocell grid’s capacity to face up to operational stresses. For avenue development geocell applications, post-installation inspections have to additionally consist of monitoring for seam motion or degradation over time, specially after heavy rainfall or temperature extremes. Implementing these QC measures ensures that HDPE geocell seams and connections stay steady and dependable at some point of the project’s lifespan.

3. Tailored Techniques for Road Construction Geocell: Enhancing Pavement Stability

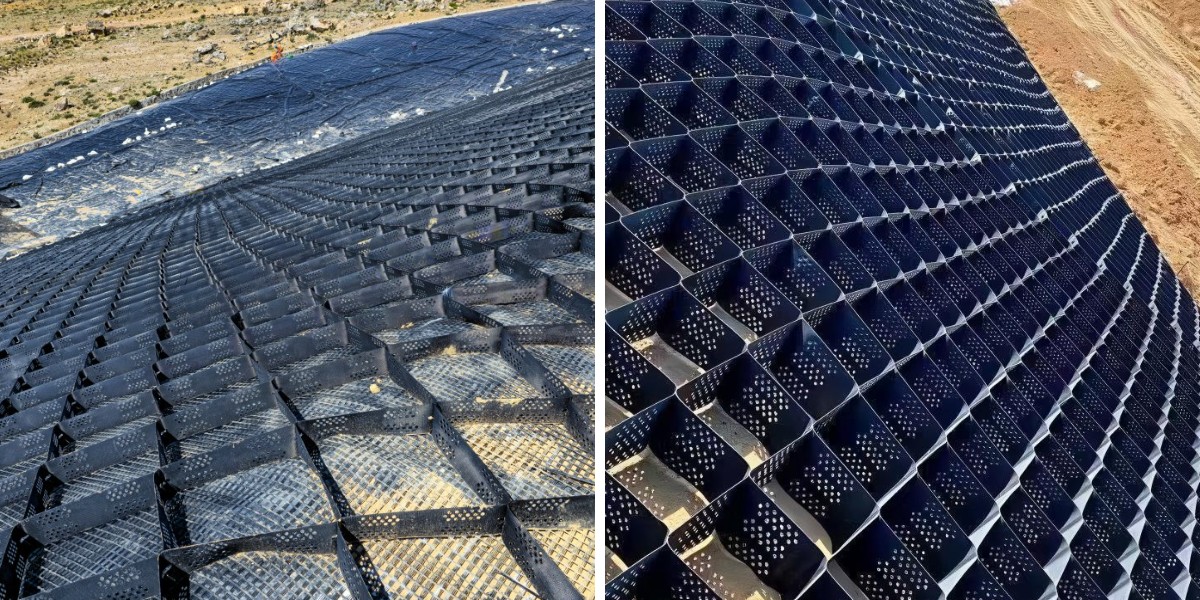

Road development is one of the most stressful functions for HDPE geocell, as the grid need to stand up to heavy automobile loads, repeated site visitors stress, and environmental elements like moisture and temperature changes. Seaming and connection methods for avenue development geocell ought to be tailor-made to these challenges, making sure a unified grid that distributes masses evenly, prevents soil lateral movement, and extends pavement lifespan. Geoweb structures designed for avenue development frequently require specialised seaming tactics to meet the industry’s strict overall performance standards.

In avenue subgrade stabilization, HDPE geocell is normally set up in layers, with seams staggered to keep away from growing non-stop susceptible lines. Thermal welding is the favored approach here, as it creates a seamless bond that can stand up to the vertical and horizontal stresses from traffic. Welded seams are located perpendicular to the path of site visitors go with the flow to decrease stress concentration—this orientation ensures that automobile hundreds are disbursed throughout the whole grid as an alternative than focusing on character seams. Additionally, area connections between geocell panels and street curbs or shoulders are strengthened with greater welds or mechanical fasteners to stop area lifting, a frequent difficulty that can lead to pavement damage.

For street embankment and slope reinforcement adjoining to roadways, HDPE geocell seaming have to accommodate the slope’s perspective whilst retaining grid integrity. Thermal welding with extrusion welders is perfect for curved or sloped seams, as it permits for unique manage over the weld bead. Seams are spaced nearer collectively on steeper slopes (typically 30–50 cm apart) to beautify stability, and the geocell grid is anchored to the slope base with heavy-duty mechanical fasteners to stop sliding. In these applications, the aggregate of thermal welding and mechanical anchoring creates a sturdy device that resists soil erosion and slope failure, defending the adjoining roadway.

Another necessary consideration for street building geocell is moisture resistance. Seams and connections ought to be totally water-resistant to stop water infiltration, which can weaken the subgrade and compromise grid stability. Thermal welding creates a water-tight seal that outperforms mechanical or adhesive connections in this regard. Additionally, post-installation sealing of all seams with HDPE-compatible sealants in addition enhances moisture resistance, making sure that the geocell machine stays high-quality even in wet or humid climates. These tailor-made strategies show how suited seaming and connection practices are integral for maximizing the overall performance of HDPE geocell in street construction.

Conclusion: Mastering Seaming & Connection for Reliable HDPE Geocell Performance

HDPE geocell’s effectiveness as a geotechnical solution hinges on the high-quality of its seaming and connections. By deciding on the proper technique (thermal welding for permanent, high-stress applications, mechanical fasteners for flexibility, and adhesive bonding for supplements), enforcing rigorous fantastic manage measures, and tailoring strategies to precise purposes like street building geocell, authorities can make certain a unified, steady grid that meets venture requirements. Geoweb structures remember on these practices to supply long-term durability, load-bearing capacity, and resistance to environmental stresses.

For engineers, contractors, and mission managers working with HDPE geocell, investing time in learning seaming and connection strategies is a rewarding endeavor. Properly completed seams and connections no longer solely stop infrastructure failure however additionally minimize upkeep charges and prolong the project’s lifespan. As geoweb structures proceed to evolve, staying up to date on the present day seaming applied sciences and first-rate practices will continue to be crucial for reaching most desirable overall performance in geotechnical engineering initiatives worldwide.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province