Geotube vs. Traditional Lagoon or Press Dewatering: A Comparative Overview

Introduction to Sludge and Sediment Dewatering

In the world of industrial, municipal, and environmental management, coping with sludge, sediment, and slurry is a consistent challenge. Whether dealing with wastewater cure residuals, industrial byproducts, or dredged materials, the intention is the same: successfully separate water from solids to minimize volume, simplify disposal, and get better precious resources. For decades, two traditional methods—lagooning and mechanical press dewatering—have dominated the landscape. However, an revolutionary and an increasing number of famous solution, regularly referred to as the geo luggage dewatering technique, is altering the game. This article gives a complete comparative overview, analyzing the operational, economic, and environmental components of geotextile filter bag structures in opposition to common approaches.

The Conventional Approach: Lagoon Dewatering

Lagoon dewatering is one of the oldest and easiest strategies for isolating solids from liquids. The method includes pumping slurry into large, shallow, lined or unlined ponds. Over time, gravity motives solids to settle at the bottom, whilst water evaporates or is decanted from the top.

How it Works: The slurry sits for weeks or months, relying on herbal processes. The settled sludge is then regularly excavated and hauled away for disposal as soon as it reaches a adequate solids content.

Key Considerations: While lagoons have a low preliminary capital fee and easy operation, they come with massive drawbacks. They require tremendous tracts of land, and the dewatering method is completely weather-dependent—rain can reverse progress. There are additionally great dangers of groundwater contamination, smell issues, and the attainable for liner failures. Furthermore, the remaining product regularly has a low solids content, making transportation costly. For initiatives like managing settled sediments, the usage of a easy silt baggage machine in a managed place can every now and then be a greater focused choice to a large, open lagoon.

The Mechanical Workhorse: Press Dewatering

Mechanical dewatering presses, such as belt presses, filter presses, and centrifuges, use pressure and filtration to separate water from solids rapidly. These structures are commonly housed in a plant or facility.

How it Works: Chemically conditioned slurry is fed into the press. Using excessive pressure, rollers, or centrifugal force, water is compelled out thru filter cloths or screens, producing a dry cake. The method is non-stop or batch-based, relying on the technology.

Key Considerations: Press dewatering affords a fast, constant procedure that yields a excessive solids cake in a compact footprint. However, it includes excessive capital expenditure, widespread electricity consumption, and ongoing operational fees for chemicals, maintenance, and knowledgeable labor. The gadget is additionally surprisingly rigid and now not effortlessly moved. For positive waste streams with nice particles, the geotextile filter bag precept operates on a comparable filtration mechanism however in a passive, containerized form.

The Innovative Solution: Geotube Dewatering Technology

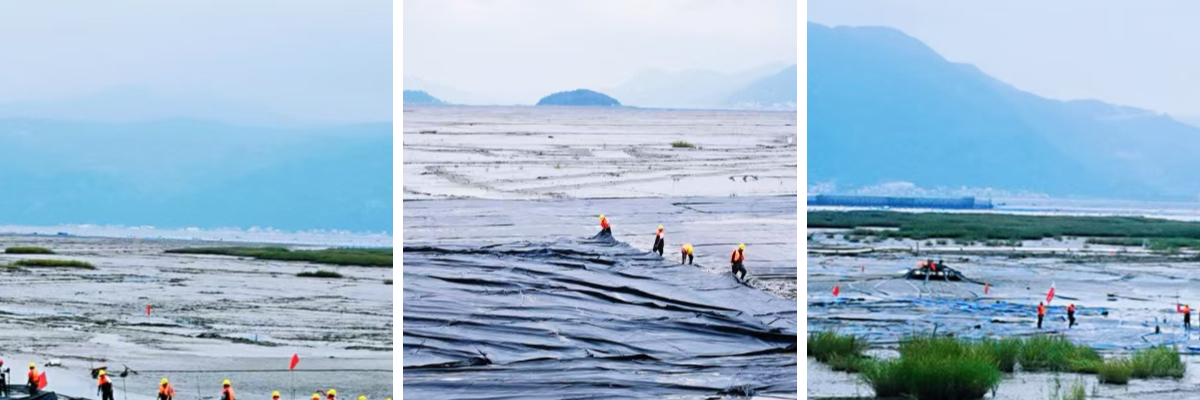

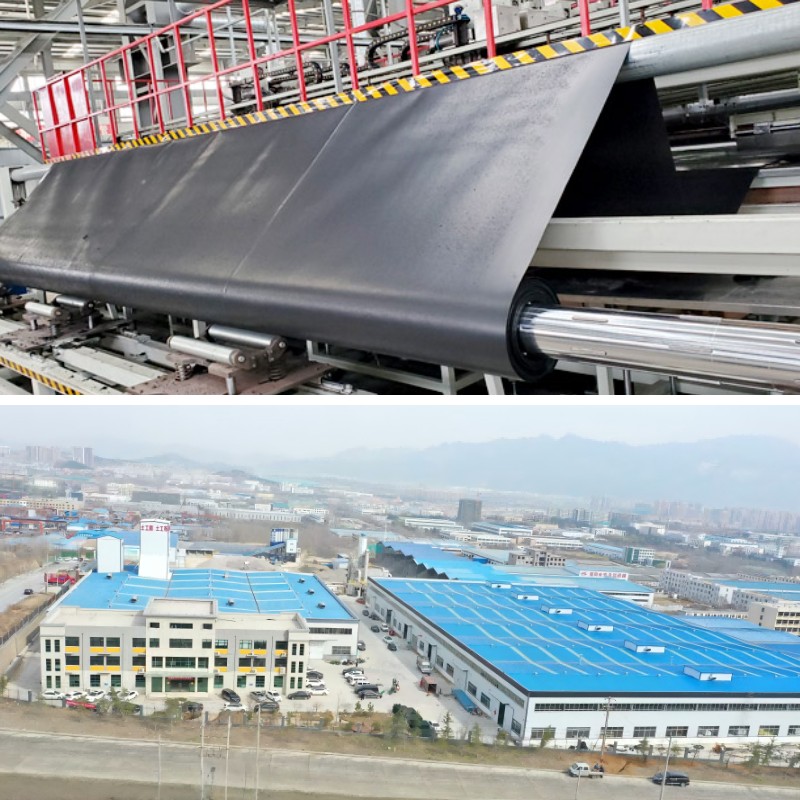

Geotube dewatering represents a modern, engineered utility of geosynthetic containers. It makes use of high-strength, permeable geotextile filter baggage designed to dewater slurry efficiently.

How it Works: The manner starts with the placement of large-diameter geo baggage dewatering devices at the site. Slurry is pumped into the bags, frequently with flocculants to bind pleasant particles. Water without delay starts offevolved to seep thru the tiny pores in the geotextile fabric, whilst solids are retained inside. The system continues till the bag is full of dewatered solids, which can then be left to similarly consolidate earlier than ultimate disposal or soil reuse.

Key Components: The coronary heart of the gadget is the geotextile filter bag itself, engineered with precise pore sizes to keep goal particles whilst permitting easy effluent to drain. For smaller-scale or turbidity manipulate applications, such as containing runoff, silt luggage hire the identical foundational technology.

Comparative Analysis: Key Factors for Decision-Making

1. Capital and Operational Costs:

Lagoon: Very low preliminary fee however excessive land cost. Minimal operational expense.

Press: Very excessive capital investment. High operational fees (energy, chemicals, labor, maintenance).

Geotube: Moderate capital value (materials and setup). Low operational costs, specifically for pumps and polymers. It provides an super balance, warding off the huge capex of presses and the hidden long-term liabilities of lagoons.

2. Efficiency and Performance:

Lagoon: Slow (can take months), weather-dependent, and produces a low-solids cake.

Press: Fast and produces the driest cake. Performance can be touchy to feed consistency and requires optimization.

Geotube: Faster than lagoons however slower than presses. Produces a reliably stable, stackable solid. Its overall performance is regular throughout more than a few materials, which include difficult-to-treat high-quality sediments. The geo baggage dewatering procedure excels in attaining huge quantity reduction.

3. Flexibility and Footprint:

Lagoon: Requires a very large, everlasting footprint.

Press: Small footprint however constant in a plant setting; now not mobile.

Geotube: Highly bendy and mobile. Units can be deployed immediately at the factor of waste era (e.g., dredging sites, pond cleanouts). The footprint is extensively smaller than a lagoon for the equal volume.

4. Environmental Impact and Safety:

Lagoon: High danger of seepage, odor, and fuel emissions. Potential for overflow.

Press: Controlled surroundings however includes chemical coping with and excessive strength use.

Geotube: Closed-container machine minimizes odor, prevents spillage, and consists of contaminants safely. The filtered effluent is regularly clear sufficient for direct discharge or recycling. Using a geotextile filter bag machine is extensively diagnosed as an environmentally preferable technology.

5. Disposal and End Result:

Lagoon: Wet sludge is luxurious to haul and might also require in addition dewatering at a landfill.

Press: Dry cake reduces hauling expenses and may additionally be appropriate for positive kinds of reuse.

Geotube: Produces a stable, contained stable mass. The whole silt baggage or geotube unit can once in a while be buried on-site (if permitted), or the dewatered fabric can be eliminated for landfill or really useful use, substantially slicing transportation costs.

Conclusion: Choosing the Right Dewatering Strategy

The preference between common strategies and geo luggage dewatering technological know-how is no longer one-size-fits-all. Lagoon dewatering can also nevertheless suffice for non-critical, long-term initiatives with considerable land and low environmental risk. Press dewatering stays imperative for high-volume municipal vegetation the place pace and most dryness are paramount.

However, for a huge array of applications—from pond and lagoon cleanouts, industrial sludge handling, and dredging tasks to agricultural waste and mine tailings—the geotextile filter bag device affords a ideal alternative. It correctly bridges the hole between the simplistic lagoon and the complicated mechanical press.

Geotube science presents a compelling mixture of cost-effectiveness, operational simplicity, environmental safety, and fantastic performance. It reduces whole challenge costs, mitigates environmental liabilities, and presents a practical, scalable solution. Whether managing large-scale sediment or imposing easy turbidity manage with silt bags, this approach deserves sturdy consideration for any modern-day dewatering mission searching for effectivity and sustainability.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province