Woven Geotextile for Soil Separation: Preventing Mixing Under Driveways and Parking Lots

Introduction: The Unseen Problem Beneath the Surface

A stable, long-lasting driveway or parking lot starts with what lies below the asphalt or concrete. The major danger to this steadiness is the gradual mixing of distinctive soil layers. When the compacted subgrade mixes with the combination base, it leads to contamination, decreased drainage, and eventual pavement failure. This is the place a quintessential geosynthetic answer comes into play. Woven geotextile fabric serve as a durable, permeable barrier mainly engineered to stop this genuine problem. By putting in a separation layer, contractors make certain structural integrity, extend pavement life, and limit long-term preservation costs. This article explores how woven geotextiles feature as the integral setting apart membrane below paved surfaces and their broader purposes in tasks like embankment reinforcement woven geotextile systems.

The Science of Separation: How Woven Geotextiles Work

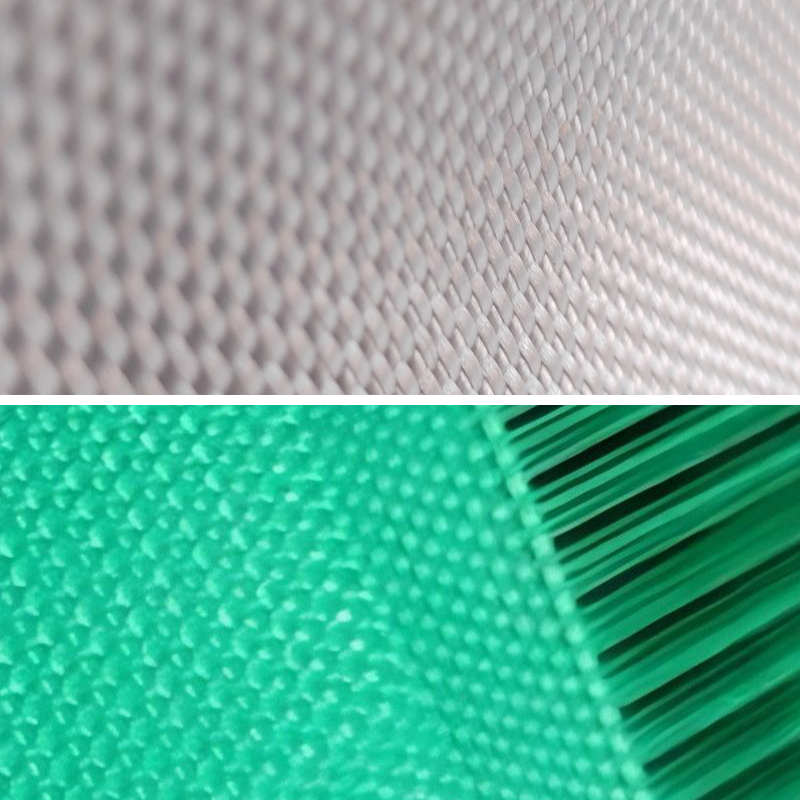

Woven geotextiles are manufactured by means of interlacing polypropylene or polyester tapes into a stable, uniform fabric. This manner creates a high-strength cloth with exactly managed pore sizes. Its major feature below pavements is mechanical separation.

When positioned between the smooth subgrade soil and the coarse combination base, the geotextile prevents the two substances from intermixing. This is crucial, specifically all through development and beneath dynamic loads. The material lets in water to ignore thru freely, stopping pore water stress build-up, whilst rigidly confining every layer in its place. The tensile power of woven geotextiles is a key asset, enabling them to face up to set up stresses and long-term masses barring tearing. This identical sturdy precept is why a railway geotextile is essential for keeping apart ballast from the subballast, making sure song steadiness underneath heavy, cyclic teach loads.

Key Benefits for Driveway and Parking Lot Projects

Using woven geotextiles as a separation layer supplies multiple, tangible advantages for pavement overall performance and task economics.

Extended Pavement Lifespan: By stopping fantastic soils from pumping up into the mixture base, the base keeps its authentic thickness and drainage capacity. This at once interprets to a decreased charge of rutting, potholing, and cracking, probably doubling or tripling the time earlier than a predominant overlay or reconstruction is needed.

Improved Load Distribution: The cloth helps distribute vehicular masses extra evenly throughout the subgrade. This is mainly critical in areas with weak, wet, or clay-rich soils, as it minimizes localized deformation and differential settlement.

Enhanced Drainage and Frost Resistance: A clean, uncontaminated combination base drains water successfully away from the subgrade. In chillier climates, this reduces the viable for frost heave, a frequent reason of pavement damage. The fabric's permeability is central to this function.

Cost and Material Savings: By stopping contamination, the combination base layer stays advantageous for its whole diagram life. This can enable for a plausible discount in base combination thickness whilst reaching equal or higher performance, main to tremendous savings on cloth and hauling costs. The precept of attaining greater with much less is additionally central to slope stabilization woven geotextile applications, the place they support and separate layers to forestall erosion and slumping.

Installation Best Practices for Maximum Effectiveness

Proper set up is integral to realizing the full advantages of the woven geotextile.

Site Preparation: The subgrade ought to be graded to the detailed format and compacted. All sharp protrusions, debris, and vegetation ought to be eliminated to stop harm to the material in the course of placement.

Geotextile Placement: Rolls are laid at once on the organized subgrade. Adjacent rolls ought to be overlapped by way of a minimal of 12 to 18 inches (or as targeted through the engineer). On curves, reducing and fan-folding can also be crucial to make sure conformity to the form except wrinkles or gaps.

Anchoring and Seaming: The cloth ought to be anchored quickly the use of staples or backfill at the edges. For imperative projects, seaming (sewing or thermal bonding) is encouraged over easy overlapping to create a continuous, monolithic barrier.

Immediate Covering: The uncovered geotextile ought to be blanketed with combination as quickly as viable to guard it from UV degradation and displacement by way of wind. Aggregate need to be dumped onto the cloth from the facet and unfold carefully, keeping off direct drops from high-quality heights that should reason punctures.

Compaction: The combination base is then compacted as per fashionable specifications. The excessive power of woven geotextiles approves them to face up to the forces of modern-day compaction equipment.

Beyond Pavements: Versatility in Geotechnical Engineering

While our focal point is on driveways and parking lots, the separation feature of woven geotextiles is necessary to infinite civil engineering applications. Their excessive tensile power and sturdy shape make them perfect for greater stressful scenarios.

In transportation infrastructure, a specialised railway geotextile performs the crucial function of isolating the ballast stone from the underlying soil, stopping fouling and preserving tune geometry underneath intense loads. For earthworks, an embankment reinforcement woven geotextile is used to assemble secure embankments over smooth foundations. Here, the cloth no longer solely separates however additionally presents tensile reinforcement, distributing masses and growing standard stability. Similarly, a slope stabilization woven geotextile is employed in erosion manage and slope repair. It separates fill substances from native soils whilst its reinforcement feature helps to anchor the slope face and guide vegetative or armoring systems.

Conclusion: The Foundational Layer for Success

Investing in a nice woven geotextile for soil separation is a minor upfront price that can pay huge long-term dividends. For property owners, developers, and contractors, it is a established insurance plan coverage in opposition to untimely pavement failure. By making sure a stable, non-mixing foundation, woven geotextiles assurance that driveways and parking plenty can stand up to years of site visitors and environmental stress. The engineering standards that make them so high quality beneath asphalt are the very equal that make certain reliability in large-scale tasks requiring an embankment reinforcement woven geotextile, a fundamental railway geotextile, or a long lasting slope stabilization woven geotextile. When planning your subsequent paving project, specifying the right woven geotextile is now not simply an add-on—it is a imperative step in constructing a shape that is designed to last.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province