Geotextile Tubes for Mine Tailings Management: Ensuring Environmental Safety & Compliance

Mine tailings— the fine, mineral-rich waste generated from ore processing—pose widespread environmental and regulatory challenges. Traditional storage techniques like tailings dams are susceptible to failure, leakage, and long-term land degradation, risking infection of groundwater, rivers, and ecosystems. In contrast, geotextile tube and geosynthetic tubes provide a modern, sustainable answer that prioritizes each environmental safety and regulatory compliance. These engineered structures streamline tailings dewatering, storage, and reuse, making them a go-to desire for mines aiming to decrease threat and meet world standards. Below are three necessary approaches geotextile tube technological know-how transforms mine tailings management, with actionable insights for implementation.

1. Geotextile Tubes: A Sustainable Replacement for High-Risk Traditional Storage

Traditional tailings storage relies closely on earthen dams, which require tremendous land areas, eat immoderate water, and raise inherent protection risks. Geotextile tube structures tackle these flaws through combining dewatering effectivity with compact storage, aligning with present day mining’s sustainability goals.

1.1 The Risks of Traditional Tailings Dams

Traditional tailings dams face three principal barriers that geosynthetic tubes eliminate: they are structurally prone (prone to erosion and failure in severe climate like heavy rain or seismic activity, as considered in failures like the 2019 Brumadinho incident that triggered loss of existence and ecosystem destruction), waste immoderate water (tailings slurry saved in dams retains up to 80% water, tying up a fundamental mining resource), and occupy giant everlasting land areas (disrupting nearby habitats and stopping post-mining land reuse).

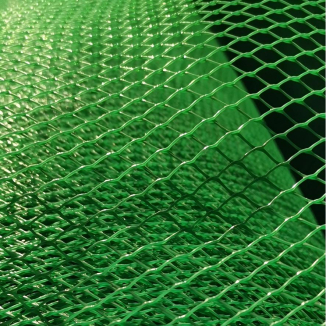

1.2 How Geotextile Tubes Work for Tailings Dewatering & Storage

A geotextile tube is a large, bendy container made from high-strength, permeable geosynthetic cloth (such as polyester or polypropylene), and its tailings administration operation follows three key steps: first, tailings slurry is pumped into the geosynthetic tube by means of high-pressure hoses, with the tube’s material permitting water to seep out (through filtration) whilst trapping strong tailings inside; next, over days to weeks, the filtered water (called “effluent”) is collected, treated, and reused in mining techniques (reducing freshwater demand by means of up to 60%), whilst strong tailings inner compact into a dense, secure mass; finally, as soon as dewatered, the geotextile tube (filled with compacted tailings) can be stacked for brief storage or used as structural factors like embankments or website barriers, and empty tubes are light-weight and convenient to transport, slicing logistical costs.

1.3 Sustainability Benefits: Less Waste, More Resource Efficiency

Geosynthetic tubes minimize the environmental footprint of tailings administration in three impactful ways: they allow water recycling (effluent from dewatering is smooth sufficient for reuse in ore processing or dirt suppression, reducing reliance on freshwater), preserve land (compact storage capability geotextile tube structures use 50–70% much less land than standard dams, and the region can be restored to grasslands, forests, or agricultural land post-use), and reduce carbon emissions (fewer substances like concrete or dam soil and decreased transportation decrease the carbon footprint of tailings operations—critical for mines pursuing net-zero goals).

2. Environmental Safety: Mitigating Tailings Risks with Geosynthetic Tubes

The important environmental risk of mine tailings is the leakage of heavy metals (e.g., lead, arsenic) and poisonous chemical compounds into soil and water. Geotextile tube structures are designed to stop this threat via strong filtration, impenetrable containment, and post-use website online restoration—protecting ecosystems and close by communities.

2.1 Leakage Prevention: The Impermeable Advantage of Geotextile Fabrics

High-quality geotextile tube fabric are engineered to block poisonous seepage: they have low permeability (a tight weave with hydraulic conductivity normally <10⁻⁹ m/s, stopping water and dissolved contaminants from passing thru and stopping heavy metals from leaching into groundwater or floor water), function strengthened seams (geosynthetic tubes use heat-welded or stitched seams more desirable than the material itself, doing away with leakage-prone vulnerable points, and producers take a look at seams for electricity and water tightness earlier than delivery), and help secondary containment (for high-risk tailings like these with excessive heavy steel content, mines regularly add a secondary liner underneath geotextile tube installations, developing a “double barrier” to forestall infection even if the tube is damaged).

2.2 Controlling Dust & Air Pollution

Dry tailings from normal storage are a foremost supply of air pollution, releasing dangerous particles, however geotextile tube structures remedy this issue: compacted tailings inner the tube remain moist and contained, stopping wind erosion, and empty geosynthetic tubes can be used as brief windbreaks round mine sites, similarly lowering dirt unfold to close by communities.

2.3 Ecosystem Restoration: From Waste Storage to Habitat Recovery

Unlike tailings dams— which regularly depart barren, unusable land—geotextile tube web sites are convenient to restore: after disposing of the tube (or leaving it as a barrier), compacted tailings can be capped with topsoil and seeded with native plants; decreased land use minimizes upfront habitat destruction, permitting neighborhood flowers and fauna to get better quicker post-mining; and case research (such as gold mines in Australia) exhibit geotextile tube web sites can be restored to practical ecosystems in 2–3 years, in contrast to 10+ years for dam sites.

3. Regulatory Compliance: Aligning Geotextile Tube Systems with Global Standards

Mines face strict rules for tailings management—from neighborhood environmental legal guidelines to global frameworks—with heavy penalties for non-compliance. Geotextile tube structures simplify compliance by means of assembly key necessities for safety, monitoring, and environmental impact.

3.1 Key Global Regulations for Tailings Management

Mines working internationally have to comply with requirements together with the Global Tailings Standard (GTS) (developed through the UN and mining groups, requiring hazard assessments, strong containment, and public disclosure of tailings plans), Canada’s Tailings Management Framework (mandating impartial facility audits, emergency response plans, and ordinary water great monitoring), and the U.S. EPA’s Mine Waste Regulations (requiring poisonous launch prevention and website online restoration to pre-mining conditions)—and geosynthetic tubes are designed to meet all these standards, as their sketch prioritizes hazard discount and transparency.

3.2 How Geotextile Tubes Simplify Compliance

Geotextile tube structures assist mines meet regulatory necessities in a couple of ways: producers furnish check facts (like cloth electricity and permeability) that mines use in chance assessments (a key GTS and Canadian framework requirement); the above-ground layout of geotextile tube structures makes it convenient to check out for damage, measure dewatering efficiency, and take a look at effluent quality, permitting rapid submission of ordinary monitoring reviews to regulators; and in contrast to dams, geosynthetic tubes have low catastrophic failure risk—if a tube is damaged, contained tailings are effortless to isolate and repair, supporting mines meet emergency preparedness rules.

3.3 Third-Party Certification: Building Trust with Regulators

To improve compliance, many mines pick geotextile tube structures with third-party certifications (such as ISO 9001 for first-class or ISO 14001 for environmental management); this certification gives impartial verification that the device meets international standards, lowering regulatory scrutiny and constructing have confidence with nearby communities.

Final Thoughts: Geotextile Tubes—The Future of Compliant, Safe Tailings Management

For mines, geotextile tube and geosynthetic tubes are extra than simply a storage solution—they are a strategic device to guard the environment, keep away from regulatory penalties, and construct long-term sustainability. By changing high-risk dams with efficient, leak-proof geotextile tube systems, mines can limit their environmental influence whilst assembly the strictest world standards.

The key to success lies in selecting the proper geotextile tube (matched to tailings kind and assignment size) and working with skilled carriers who provide testing, installation, and compliance support. With the proper system, mines can flip a legal responsibility (tailings) into an probability to reveal environmental leadership.

If you want a tailor-made Geotextile Tube Sizing & Compliance Checklist for your mine’s particular tailings project—including cloth resolution hints and regulatory checkpoints—let me create one for you. It will assist you rapidly align your tailings administration diagram with security requirements and keep away from compliance gaps.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province