Geomembranes in Mining: Preventing Acid Drainage & Soil Pollution

Mining operations are quintessential for extracting treasured minerals that electrical electrical power industries and economies worldwide. However, they in addition pose big environmental risks, with acid drainage and soil air air air air pollution being two of the most pressing issues. Left unaddressed, these troubles can devastate shut via the use of ecosystems, contaminate water sources, and harm human health. Fortunately, the use of geomembranes has emerged as a reliable reply to mitigate these risks. In this article, we will detect out how geomembranes, which consist of hdpe geomembrane, impermeable geomembrane, and textured geomembrane, play a critical attribute in stopping acid drainage and soil air air air air pollution in mining sites.

The Growing Threat of Acid Drainage and Soil Pollution in Mining

Mining activities, such as coal mining, metal ore extraction, and mineral processing, can disrupt the natural steadiness of the earth’s crust. One of the indispensable problems is acid mine drainage (AMD), which takes area when sulfide minerals in mine waste react with oxygen and water to produce sulfuric acid. This acidic water can leach heavy metals like lead, mercury, and arsenic from the surrounding rock, creating a poisonous mixture that flows into rivers, lakes, and groundwater. AMD now now now now not clearly kills aquatic existence then as soon as extra in addition renders water unfit for human consumption and agricultural use.

Soil air pollution is some special quintessential hassle linked to mining. Mine tailings, the waste sources left after mineral extraction, in many cases include excessive concentrations of toxic substances. When these tailings are now now now no longer pinnacle contained, they can seep into the soil, altering its chemical composition and reducing its fertility. Contaminated soil can harm plant growth, disrupt the elements chain, and even pose health risks to human beings who come into contact with it or devour plant existence grown in polluted areas. The scale of these troubles is alarming, making tremendous mitigation strategies crucial for sustainable mining practices.

To fighting these threats, mining corporations are an creating range of large turning to geomembranes. Among the a great fluctuate types available, the hdpe geomembrane stands out for its sturdiness and resistance to chemicals, making it an fine pick out for stopping acid drainage and soil pollution.

Understanding Geomembranes: Key Types and Their Roles in Mining

Geomembranes are artificial membranes designed to act as barriers in opposition to the waft of drinks and gases. In mining, they are used to line mine pits, tailings ponds, and waste storage areas, stopping the leakage of toxic resources into the environment. There are a extent of sorts of geomembranes, each and every and every and every and every with wonderful homes that make them wonderful for particular mining applications.

The impermeable geomembrane is a quintessential type in mining. As its title suggests, it has highly low permeability, making nice that even small components of toxic drinks cannot seep through. This is quintessential for containing acid mine drainage and stopping it from reaching groundwater or ground water sources. Impermeable geomembranes are commonly made from sources like high-density polyethylene (HDPE), polyvinyl chloride (PVC), and ethylene propylene diene monomer (EPDM), each and each and every and each and every imparting fantastic tiers of chemical resistance and flexibility.

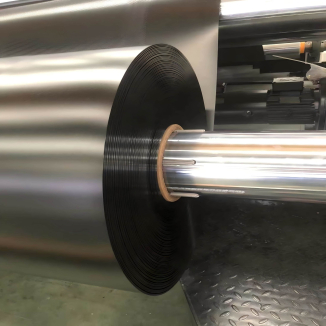

The hdpe geomembrane is one of the most significantly used impermeable geomembranes in mining. HDPE is a strong, rigid fabric that can stand up to harsh mining conditions, inclusive of publicity to acidic drinks and excessive temperatures. It is in addition resistant to UV radiation, which helps furnish up degradation over time. Additionally, HDPE geomembranes are reachable to set up and weld, developing a seamless barrier that minimizes the hazard of leaks. Their prolonged lifespan and low safety necessities make them a least highly-priced reply for mining firms looking to prevent environmental impact.

Another quintessential sort of geomembrane in mining is the textured geomembrane. Unlike effortless geomembranes, textured geomembranes have a tough flooring that affords elevated friction. This is in distinct in fact simply useful in steep-slope mining applications, such as lining the elements of mine pits or tailings dams. The textured flooring prevents the geomembrane from slipping, making pleasant that it stays in place and continues its barrier function. Textured geomembranes can be made from HDPE or extraordinary materials, and they furnish the equal impermeable properties as their convenient counterparts, making them a versatile desire for a vary of mining sites.

Each vary of geomembrane performs a extraordinary function in stopping acid drainage and soil pollution. By discovering out on the desirable geomembrane for a unique mining application, businesses can effectually comprise toxic factors and guard the environment.

How HDPE Geomembrane Mitigates Acid Drainage in Mining Sites

Acid mine drainage is a persistent trouble in mining, on the specific hand the hdpe geomembrane has set up to be a relatively exceptional reply for mitigating its impact. Let’s take a nearer show off up at how HDPE geomembranes work to cease AMD and shield water sources.

First, HDPE geomembranes have extremely good chemical resistance. Acid mine drainage is pretty acidic, with a pH stage frequently beneath 4, and consists of immoderate concentrations of heavy metals. The chemical steadiness of HDPE manageable that it does no longer react with these acidic substances, stopping degradation of the membrane. This ensures that the geomembrane stays intact and purposeful for decades, even in the most harsh mining environments.

Second, the impermeable nature of HDPE geomembranes is key to containing AMD. When hooked up as a liner in mine pits or tailings ponds, the hdpe geomembrane creates a barrier that stops acidic water from seeping into the underlying soil and groundwater. The seamless welding of HDPE sheets in addition enhances this barrier, inserting off gaps the location leaks ought to occur. Mining companies can in addition set up a geotextile underlayer under the HDPE geomembrane to furnish larger beneficial useful resource and supply up punctures from rocks or one of a range debris, in a same way reducing the hazard of leakage.

In addition to containing AMD, HDPE geomembranes in addition beneficial aid in the cure of acidic water. Some mining web net web sites use HDPE-lined cure ponds the neighborhood chemical elements are used to neutralize the acid and precipitate heavy metals. The impermeable HDPE liner ensures that the dealt with water does now no longer contaminate the surrounding environment till now than it is launched or reused. This combination of containment and remedy makes HDPE geomembranes a whole reply for managing acid mine drainage.

Real-world examples spotlight the effectiveness of HDPE geomembranes in mining. A coal mining operation in a mountainous area used to be struggling with excessive AMD that used to be contaminating a shut through performance of river. After inserting in an hdpe geomembrane liner in the mine’s tailings pond, the industrial company organization placed a giant minimize charge in the extent of acidic water leaking into the soil. Within a year, the water remarkable in the river improved, and aquatic existence commenced to return. This success story demonstrates how HDPE geomembranes can make a tangible huge difference in defending the environment from acid drainage.

The Role of Impermeable Geomembrane in Preventing Soil Pollution

Soil air air air air pollution from mining things to do can have long-term penalties for ecosystems and human health, on the exceptional hand the impermeable geomembrane is a first-rate pc for stopping this damage. Here’s how impermeable geomembranes work to guard soil in mining sites.

Mine tailings, which are the critical furnish of soil air air air air pollution in mining, consist of a mix of poisonous minerals, heavy metals, and chemicals. When these tailings are saved in open piles or unlined ponds, rainwater can wash the toxic factors into the surrounding soil, contaminating it. Impermeable geomembranes act as a barrier between the tailings and the soil, stopping the leaching of toxic materials. By lining tailings ponds and waste storage areas with an impermeable geomembrane, mining companies can make fantastic that the soil stays free from contamination.

The low permeability of these geomembranes is crucial. Even small components of toxic drinks seeping into the soil can accumulate over time, predominant to immoderate pollution. Impermeable geomembranes have a permeability cost that is a full-size vary of orders of magnitude restriction than natural soil, making certain that simply no poisonous sources skip through. This is notably speakme essential in areas with excessive rainfall, the neighborhood the chance of leaching is increased.

Impermeable geomembranes in addition help in the rehabilitation of mining sites. After mining operations cease, the land have to be restored to a usable state. By the utilization of an impermeable geomembrane to consist of any closing waste materials, groups can end in addition soil air air air air pollution and create a reachable groundwork for reforestation or one-of-a-kind land uses. The geomembrane acts as a long-term barrier, making exceptional that the soil stays uncontaminated for years to come.

In addition to tailings storage, impermeable geomembranes are in addition used in top notch mining sides to give up soil pollution. For example, they are used to line the base of mine pits to give up the leakage of poisonous water into the soil below. They are in addition used in the storage of chemical materials used in mining processes, making nice that any spills do now no longer contaminate the surrounding soil. The versatility of impermeable geomembranes makes them an essential aspect of any mining company’s environmental protection strategy.

Textured Geomembrane: Enhancing Safety and Performance in Mining Applications

While all geomembranes play a attribute in stopping environmental damage in mining, the textured geomembrane affords wonderful advantages that adorn protection and frequent favored usual overall performance in extraordinarily good applications. Let’s find out out how textured geomembranes make contributions to extraordinarily particular mining operations.

One of the vital challenges in mining is making advantageous that geomembranes proceed to be in place, in the primary in areas with steep slopes. Smooth geomembranes can be inclined to slipping on steep surfaces, which can lead to gaps in the barrier and prolong the hazard of leaks. Textured geomembranes get to the bottom of this hassle with their hard surface, which offers accelerated friction between the geomembrane and the underlying soil or geotextile. This friction prevents the geomembrane from sliding, even on slopes with angles of up to 30 ranges or more. This is by means of and giant quintessential in tailings dams, the vicinity the stability of the dam is integral to stopping catastrophic screw ups that can launch massive components of toxic waste into the environment.

The textured floor of these geomembranes in addition improves the steadiness of the overlying material. In tailings ponds, the textured geomembrane affords a tightly closed base for the tailings, reducing the hazard of contract and uneven loading. This helps to maintain the integrity of the pond and furnish up the formation of cracks or leaks. Additionally, the textured flooring can aid to distribute the weight of the tailings expanded evenly, in addition bettering the steadiness of the structure.

Textured geomembranes in addition furnish the equal impermeable residences as available geomembranes, making certain that they correctly quit the leakage of toxic substances. Many textured geomembranes are made from HDPE, combining the sturdiness and chemical resistance of hdpe geomembrane with the giant friction of a textured surface. This makes them great for a large fluctuate of mining applications, from lining steep-slope mine pits to protecting tailings dams.

Another accumulate of textured geomembranes is their ease of installation. Despite their hard surface, they can be hooked up the utilization of the equal methods as available geomembranes, together with welding and anchoring. The textured floor does no longer intervene with the welding process, making certain that a seamless barrier is created. This makes textured geomembranes a clever want for mining groups looking out to enhance safety and daily frequent common overall performance barring developing set up complexity or costs.

Best Practices for Installing and Maintaining Geomembranes in Mining

To make gorgeous that geomembranes, alongside with hdpe geomembrane, impermeable geomembrane, and textured geomembrane, correctly provide up acid drainage and soil pollution, applicable set up and renovation are essential. Here are some top notch practices that mining businesses prefer to follow.

Installation Best Practices

1.Site Preparation: Before inserting in a geomembrane, the internet web site have to be proper prepared. This consists of clearing the vicinity of rocks, debris, and vegetation that ought to puncture the membrane. The soil have to in addition be compacted to create a smooth, tightly closed base.

2.Proper Welding: For thermoplastic geomembranes like HDPE, welding is a quintessential step in growing a seamless barrier. Mining corporations ought to use professional technicians and splendid welding equipment to make wonderful that the welds are sturdy and leak-free. Welds ought to be examined the use of techniques like air stress making an try out or vacuum checking out to be aware any defects.

3.Anchoring: Geomembranes ought to be securely anchored to end movement. This is many times vital for textured geomembrane used on steep slopes. Anchoring strategies can embody trench anchoring, the vicinity the membrane is buried in a trench alongside the section of the site, or mechanical anchoring, the utilization of bolts or clips to be a phase of the membrane to a concrete or steel edge.

4.Overlap and Seaming: When inserting in larger than one sheets of geomembrane, the overlaps want to be adequate to make effective a tight seal. The extent of overlap depends upon upon on the variety of geomembrane and the set up method, then as soon as larger it is frequently between 10 and 30 centimeters. Seams have to be cautiously aligned and welded to give up leaks.

Maintenance Best Practices

1.Regular Inspections: Mining groups pick out to habits every day inspections of geomembranes to hit upon out any symptoms and signs and symptoms and symptoms of damage, such as punctures, tears, or weld failures. Inspections have to be carried out at least as hastily as a year, and greater usually after excessive regional local weather occasions like heavy rain or snow.

2.Prompt Repairs: Any injury to the geomembrane have to be repaired at as shortly as to quit leaks. Small punctures can be repaired the utilization of patch kits, even as large tears might also moreover in addition in addition require altering a area of the membrane. Repairs have to be executed through skilled technicians the use of best fantastic elements to make sure that the barrier stays intact.

3.Monitoring Leaks: In addition to viewed inspections, mining companies have to use monitoring constructions to be conscious leaks. These constructions can consist of groundwater monitoring wells, which measure the super of water below the geomembrane, or digital leak detection systems, which use sensors to pick out out leaks in real-time.

4.Protecting the Geomembrane: Geomembranes have to be blanketed from damage in the route of mining operations. This can embody inserting a geotextile cowl over the membrane to give up punctures from heavy equipment, or limiting get entry to to the regional to preserve away from unintended damage.

By following these exquisite practices, mining businesses can make incredible that their geomembranes proceed to be in proper circumstance and proceed to cease acid drainage and soil air air air air pollution for years to come.

The Future of Geomembranes in Sustainable Mining

As the mining company continues to focal component on sustainability and lowering its environmental impact, the use of geomembranes is expected to grow. Advancements in geomembrane science are making them even higher superb at stopping acid drainage and soil pollution, even as in addition reducing charges and bettering set up efficiency.

One place of innovation is the enchancment of massive extended lasting and chemical-resistant geomembranes. Researchers are working on new factors that can stand up to even harsher mining conditions, such as greater concentrations of acid and heavy metals. For example, modified hdpe geomembrane with more best chemical resistance is being examined in mining internet internet net websites with immoderate AMD, exhibiting promising results. These inclinations will enable geomembranes to be used in accelerated difficult mining applications, in addition growing their characteristic in environmental protection.

Another vogue is the integration of wise science into geomembranes. Smart geomembranes are geared up with sensors that can expose the membrane’s united states of affairs in real-time, detecting leaks, temperature changes, and great manageable issues. This lets in mining businesses to reply rapidly to problems, reducing the hazard of environmental damage. Smart geomembranes can in addition furnish facts on the daily frequent everyday overall performance of the membrane over time, assisting organizations optimize their renovation schedules and prolong the lifespan of the geomembrane.

The use of recycled components in geomembrane manufacturing is in addition gaining traction. As the mining organisation appears to avoid its carbon footprint, the utilization of recycled plastic to make geomembranes is a sustainable option. Recycled impermeable geomembrane and textured geomembrane furnish the equal frequent normal normal overall performance as these made from virgin materials, at the equal time as reducing the extent of plastic waste despatched to landfills. This now no longer certainly blessings the environment on the extraordinary hand in addition helps mining corporations meet their sustainability goals.

In addition to technological advancements, there is in addition a creating focal component on the spherical economic machine in the mining industry. This consists of the reuse and recycling of geomembranes at the grant up of their lifespan. Instead of disposing of historic geomembranes, mining companies can recycle them into new products, lowering waste and conserving resources. This spherical strategy to geomembrane use is an crucial step in the route of large sustainable mining practices.

Overall, the future of geomembranes in mining is bright. With ongoing technological enhancements and a growing dedication to sustainability, geomembranes will proceed to play a quintessential attribute in stopping acid drainage and soil pollution, assisting the mining employer attribute massive responsibly and defend the environment for future generations.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province